Casting process for bolt hole of large-scale ductile iron main bearing cover casting process

A main bearing cap and casting process technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of difficult processing, easy to produce iron-clad sand, and high cost, so as to improve production efficiency, save production costs, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

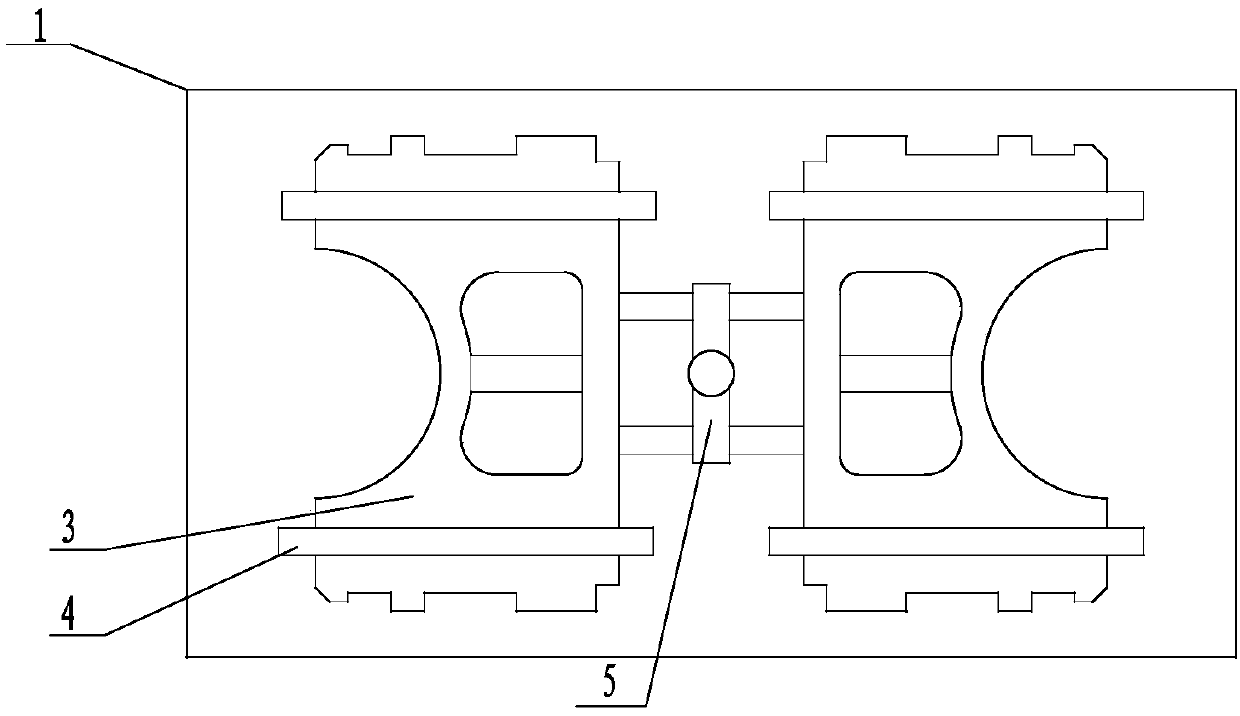

[0031] The test was carried out on the 270 main bearing cap made of QT600-3,

[0032] Determine the size of the ceramic tube 4 according to the 270 main bearing cap and purchase the corundum-mullite ceramic tube 4. This type of ceramic tube has high refractoriness and avoids the occurrence of sintering defects.

[0033] Set the fixed core head of the ceramic tube according to the size of the ceramic tube, and mold it with resin sand.

[0034] The casting sand mold 3 is painted with coating (the coating can be the coating of graphite type coating, quartz powder, zircon powder, mullite powder etc. as aggregate), and dry.

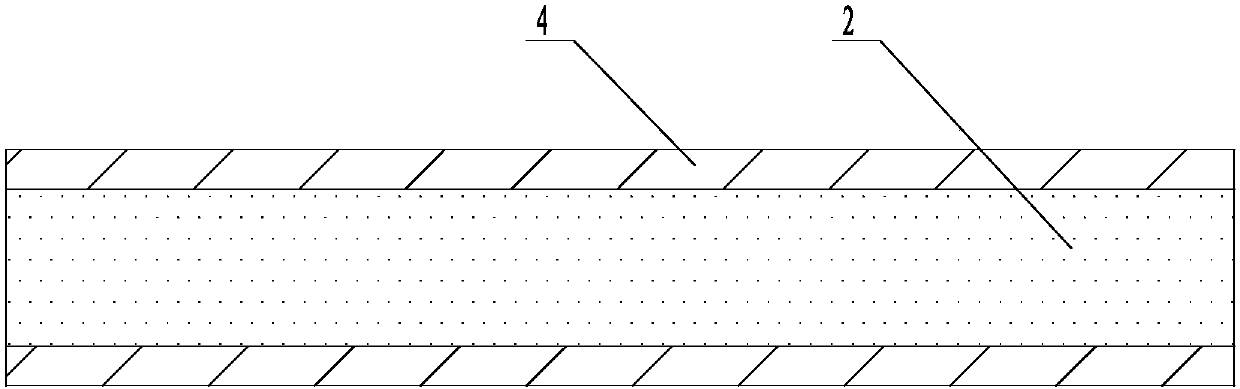

[0035] The middle of the ceramic tube is filled with furan resin sand 2 so that the ceramic tube 4 will not break when heated.

[0036] Brush the outer wall of the ceramic tube with alcohol-based refractory paint for 1 to 2 times (the paint can be graphite-based paint, quartz powder, zircon powder, mullite powder, etc. as aggregate) to prevent sintering, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com