Recycling equipment for scrap ceramic tiles in scrap decoration building materials

A technology for waste ceramic tile recycling and processing, applied in grain processing and other directions, can solve the problems of low work efficiency, high labor intensity, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

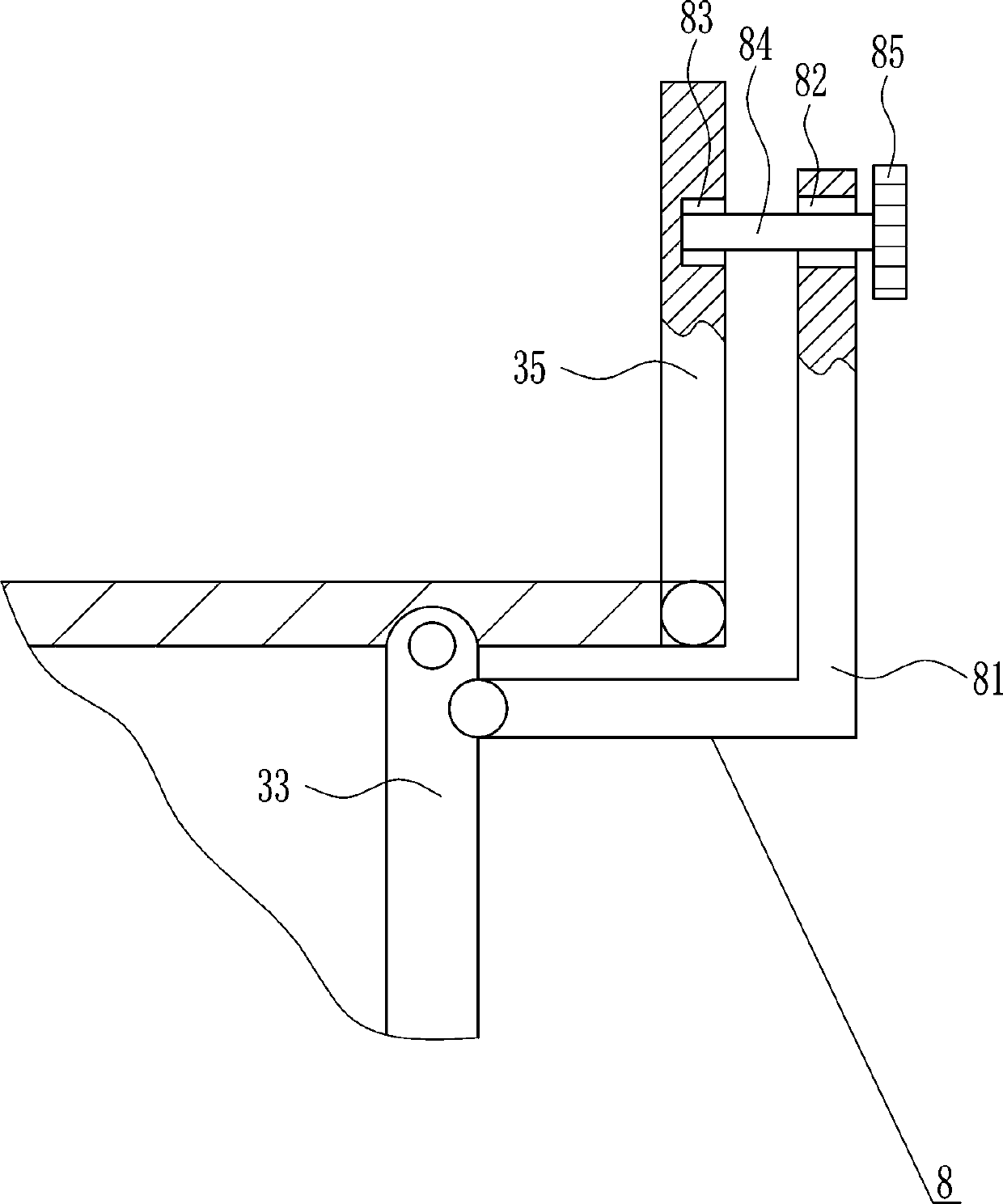

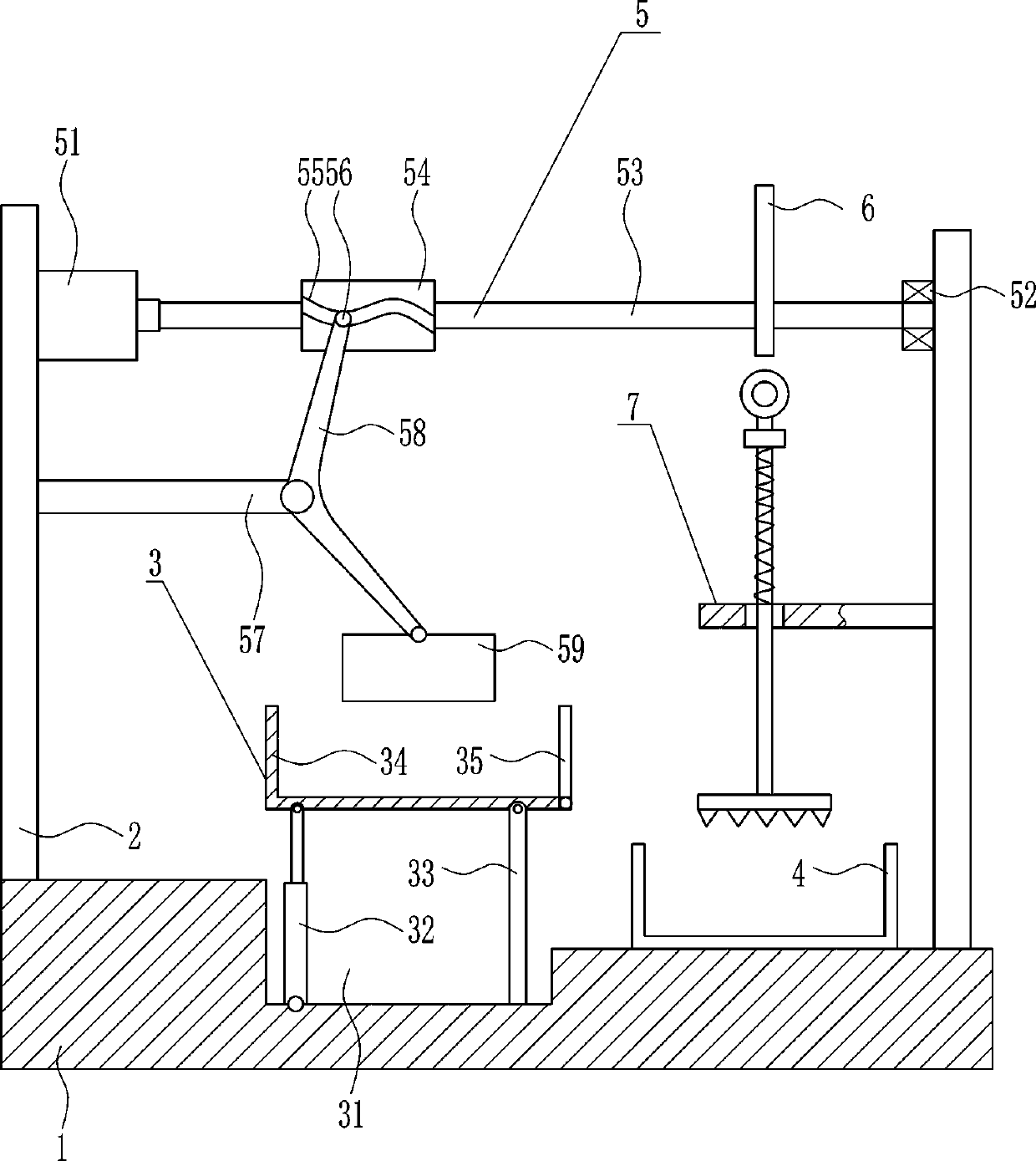

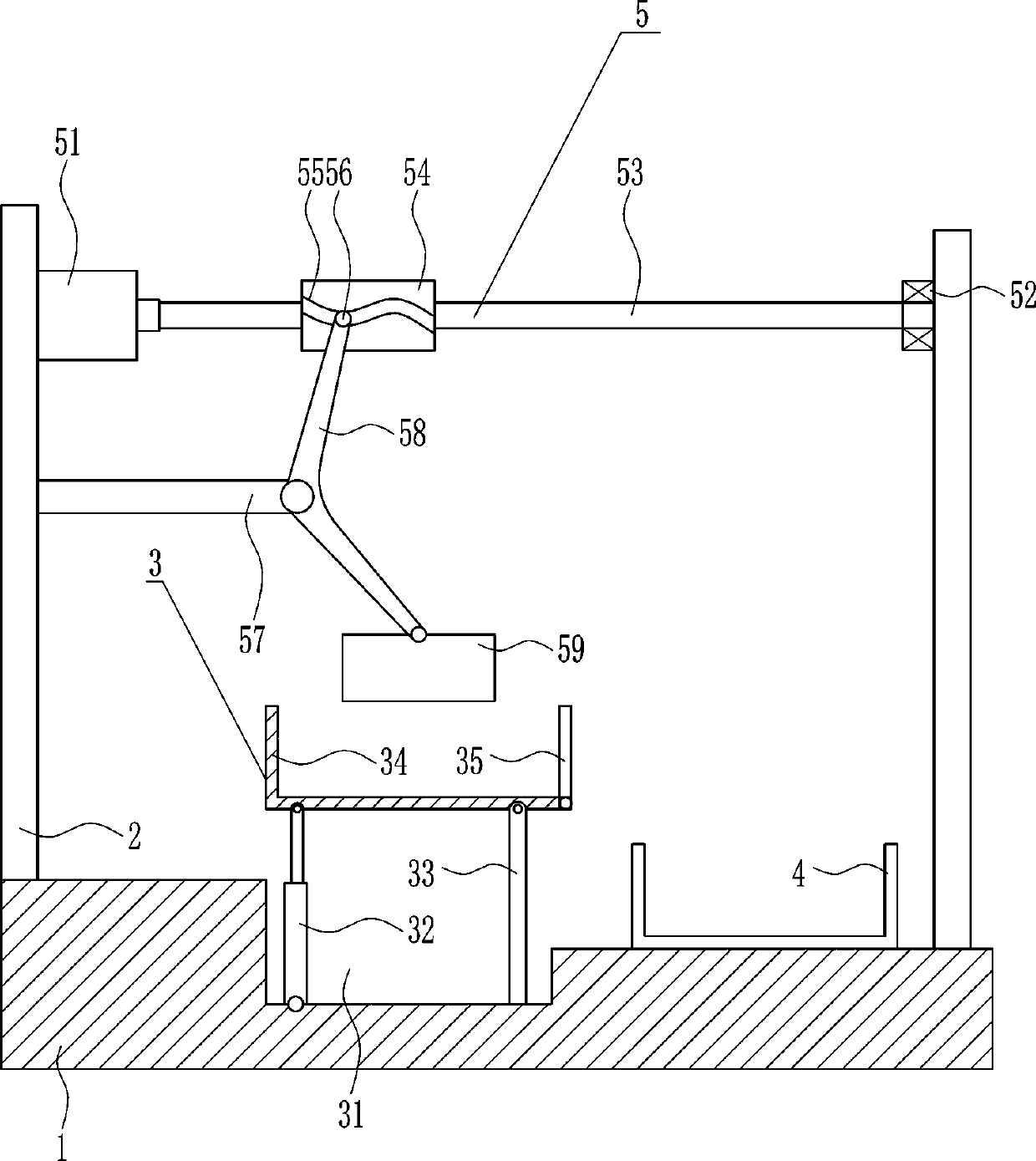

[0034] A recycling and processing equipment for waste ceramic tiles in waste decoration building materials, such as Figure 1-6 As shown, it includes a base 1, a support 2, a placement device 3, a collection frame 4, and a first processing device 5. The top of the base 1 is vertically installed with a support 2 in a symmetrical way connected by bolts, and the left side between the two supports 2 A placement device 3 is provided, and the top of the base 1 on the right side of the placement device 3 is provided with a collection frame 4, the collection frame 4 is located between the two supports 2, and the placement part of the placement device 3 is located at the upper left of the collection frame 4, between the two supports 2 The upper part is provided with a first processing device 5, and the processing part of the first processing device 5 is located directly above the placing part of the placing device 3.

Embodiment 2

[0036] A recycling and processing equipment for waste ceramic tiles in waste decoration building materials, such as Figure 1-6 As shown, it includes a base 1, a support 2, a placement device 3, a collection frame 4, and a first processing device 5. The top of the base 1 is vertically installed with a support 2 in a symmetrical way connected by bolts, and the left side between the two supports 2 A placement device 3 is provided, and the top of the base 1 on the right side of the placement device 3 is provided with a collection frame 4, the collection frame 4 is located between the two supports 2, and the placement part of the placement device 3 is located at the upper left of the collection frame 4, between the two supports 2 The upper part is provided with a first processing device 5, and the processing part of the first processing device 5 is located directly above the placing part of the placing device 3.

[0037] The placement device 3 includes a cylinder 32, a pole 33, a ...

Embodiment 3

[0039] A recycling and processing equipment for waste ceramic tiles in waste decoration building materials, such as Figure 1-6 As shown, it includes a base 1, a support 2, a placement device 3, a collection frame 4, and a first processing device 5. The top of the base 1 is vertically installed with a support 2 in a symmetrical way connected by bolts, and the left side between the two supports 2 A placement device 3 is provided, and the top of the base 1 on the right side of the placement device 3 is provided with a collection frame 4, the collection frame 4 is located between the two supports 2, and the placement part of the placement device 3 is located at the upper left of the collection frame 4, between the two supports 2 The upper part is provided with a first processing device 5, and the processing part of the first processing device 5 is located directly above the placing part of the placing device 3.

[0040] The placement device 3 includes a cylinder 32, a pole 33, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com