Farm wastewater treatment method

A sewage treatment method and farm technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of insufficient treatment of suspended matter, long treatment reaction time, and complicated process and other problems, to achieve excellent results, achieve flocculation and precipitation, and inhibit biological reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

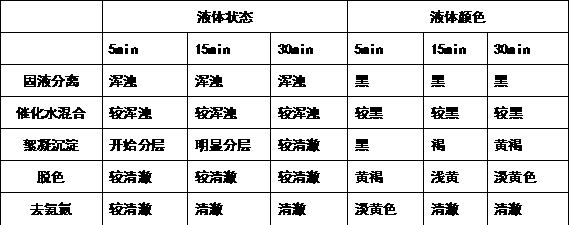

[0027] A method for treating sewage in a farm, comprising the steps of:

[0028] Step 1, separate the sewage from the farm from wet to dry, discharge the solid dregs, and send the liquid sewage into the mixing device to mix with the catalytic water device at a ratio of 1:1 and deodorize;

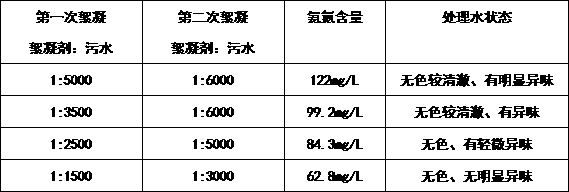

[0029] Step 2, adding a flocculant to the liquid sewage mixed and deodorized in step 1 and catalytic water for mixing, and then performing sedimentation treatment, discharging the settled sediment, and sending the liquid part to the next step;

[0030] Step 3, adding alum diluent to the liquid part treated in step 2 and performing stirring, mixing and sedimentation treatment, discharging the treated sediment, and sending the liquid part to the next step;

[0031] Step 4, adding alum diluent to the liquid part after step 3 treatment, and adding catalytic water at the same time, after mixing, sedimentation is carried out again, after sedimentation, the sediment is discharged, and the remaining...

Embodiment 2

[0034] A method for treating sewage in a farm, comprising the steps of:

[0035] Step 1, separate the sewage from the farm from wet to dry, discharge the solid dregs, and send the liquid sewage into the mixing device to mix with the catalytic water device at a ratio of 1:1 and deodorize;

[0036] Step 2, adding a flocculant to the liquid sewage mixed and deodorized in step 1 and catalytic water for mixing, and then performing sedimentation treatment, discharging the settled sediment, and sending the liquid part to the next step;

[0037] Step 3, adding alum diluent to the liquid part treated in step 2 and performing stirring, mixing and sedimentation treatment, discharging the treated sediment, and sending the liquid part to the next step;

[0038] Step 4, adding alum diluent to the liquid part after step 3 treatment, and adding catalytic water at the same time, after mixing, settling again, after settling, the sediment is discharged, and the remaining liquid is discharged int...

Embodiment 3

[0043] A method for treating sewage in a farm, comprising the steps of:

[0044] Step 1, separate the sewage from the farm from wet to dry, discharge the solid dregs, and send the liquid sewage into the mixing device to mix with the catalytic water device at a ratio of 1:1 and deodorize;

[0045] Step 2, adding a flocculant to the liquid sewage mixed and deodorized in step 1 and catalytic water for mixing, and then performing sedimentation treatment, discharging the settled sediment, and sending the liquid part to the next step;

[0046] Step 3, adding alum diluent to the liquid part treated in step 2 and performing stirring, mixing and sedimentation treatment, discharging the treated sediment, and sending the liquid part to the next step;

[0047] Step 4, adding alum diluent to the liquid part after step 3 treatment, and adding catalytic water at the same time, after mixing, sedimentation is carried out again, after sedimentation, the sediment is discharged, and the remaining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com