Wood slotting robot with depth adjusting function

An adjustable and robotic technology, used in slotting machines, wood processing appliances, mortising machines, etc., can solve the problems of no rollers and brushes, inability to remove sawdust waste, and inability to prevent sawdust from splattering, etc. The effect of drifting and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

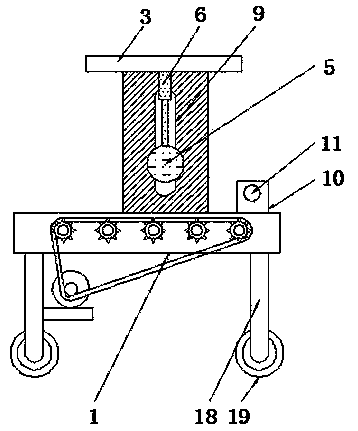

[0021] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a wood slotting robot with adjustable depth, including a workbench 1, a mounting frame 2 is installed on the top of the workbench 1, a horizontal plate 3 is installed on the top of the mounting frame 2, and The inside of the mounting bracket 2 is provided with a perforation 9, and the inside of the perforation 9 is installed with a first roller 4. One end of the first roller 4 is equipped with a bearing 7, and the outside of the first roller 4 is covered with a blade 8. The other end of the roller 4 is equipped with a first motor 5, a hydraulic rod 6 is installed above the first motor 5, a fixed block 10 is installed on the top of the workbench 1 near the rear side of the mounting frame 2, and the inside of the fixed block 10 is installed with The second roller 11, a second motor 14 is installed on one end of the second roller 11, and a cylinder 12 is installed on the outside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com