Lifting seat that can be fixed freely

A lifting seat, free technology, applied in the field of lifting seat, can solve the problems of unevenness, position deviation from the original position, and the cloth is prone to rollover, etc., and achieves the effect of convenient use and exquisite structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below according to the drawings and embodiments.

[0019] refer to Figure 1-Figure 5 , a lifting seat capable of being freely fixed, comprising:

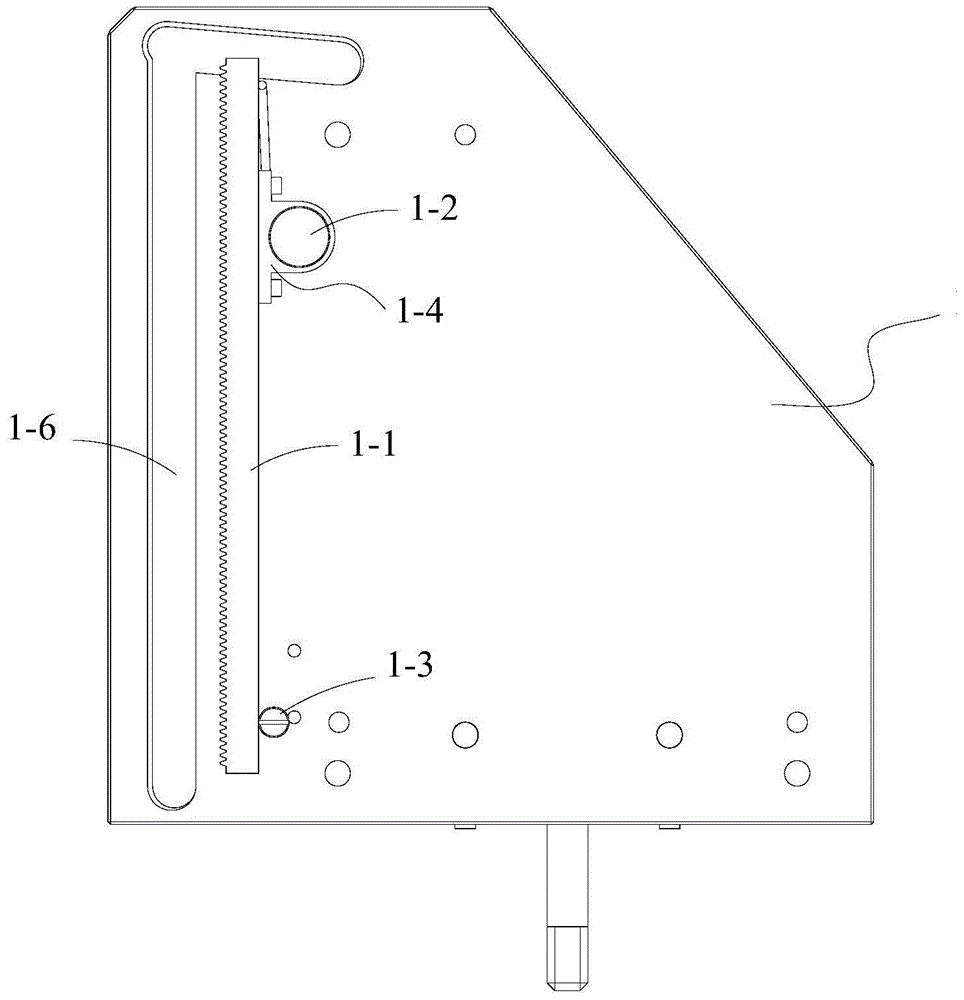

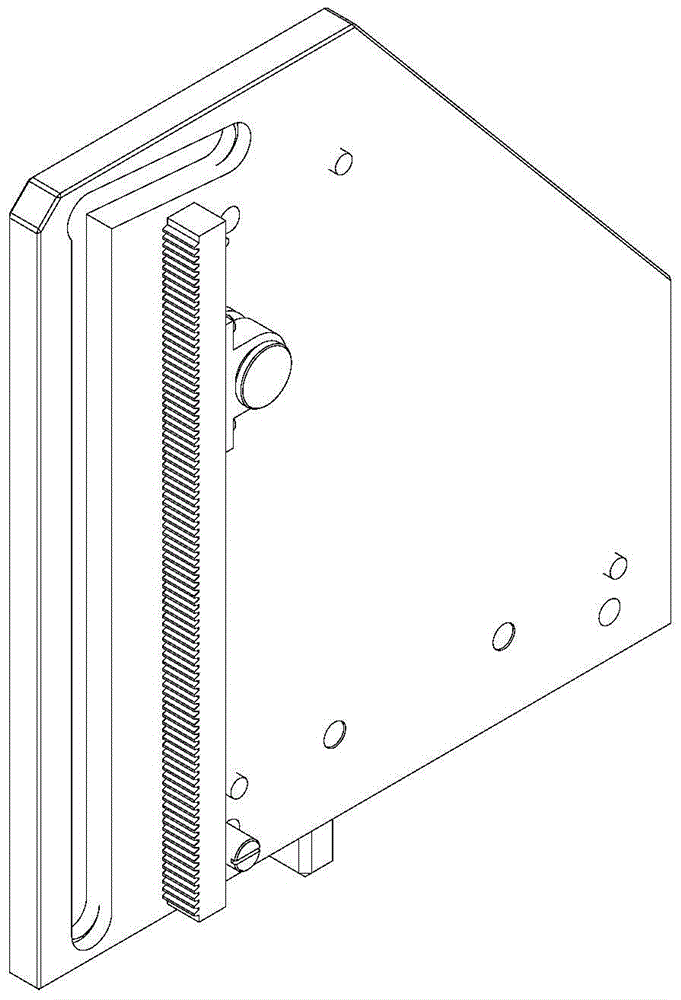

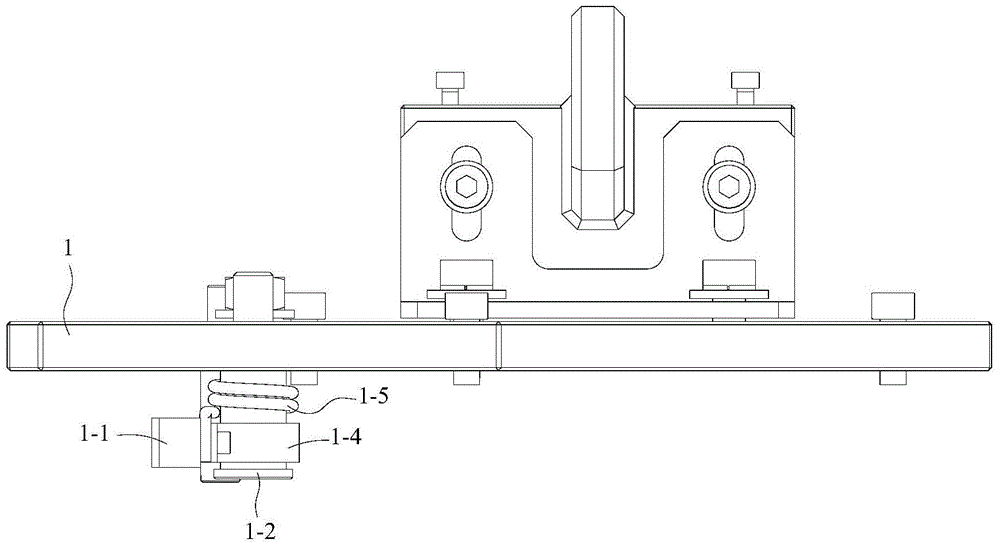

[0020] Two lifting seats 1 are symmetrically located on both sides of the above-mentioned lifting frame 1, and the inner surface of the above-mentioned lifting seat 1 is provided with a vertical rack 1-1, and the above-mentioned rack 1-1 is used for lifting and lowering of the cloth pressing device.

[0021] The inner surface of the above-mentioned lifting seat 1 is provided with an upper positioning pin 1-2 and a lower positioning pin 1-3, and the upper half of the back of the above-mentioned rack 1-1 is provided with a snap ring 1-4, and the above-mentioned snap ring 1-4 slides Set on the above-mentioned upper positioning pin 1-2, the above-mentioned upper positioning pin 1-2 is set with a rack recovery spring 1-5, and one end of the above-mentioned rack recovery s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com