Primary lithium battery with high discharging efficiency

A discharge efficiency and battery technology, which is applied to the electrodes of primary batteries, components of primary batteries, non-aqueous electrolyte batteries, etc., and can solve the problems of broken metal lithium in the negative lithium strip, safety hazards, and small thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

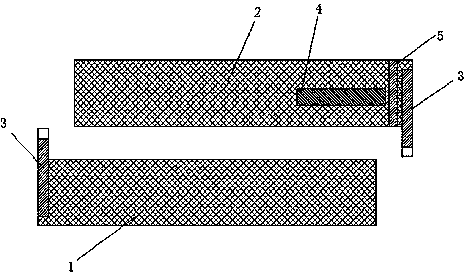

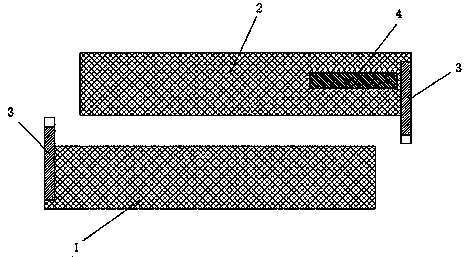

[0015] like figure 2 Shown: a lithium primary battery with high discharge efficiency, including a positive electrode sheet 1, a diaphragm, a lithium strip negative electrode sheet 2, and a tab 3 arranged on the positive and negative electrode sheets, the positive electrode sheet 1, the diaphragm and the lithium strip negative electrode Sheet 2 is wound together with the tab end of the positive electrode sheet as the starting end, and an inhibition reaction area is provided at the winding tail end of the lithium strip negative electrode sheet 2; a polymer tape sheet 4 is provided on the inhibition reaction area ; A groove 5 for stopping the reaction is provided between the tab 3 of the lithium strip negative electrode sheet 2 and the polymer tape sheet 4 . The formation of the positive plate is as follows: Weigh 1843g of heat-treated electrolytic manganese dioxide, 37g of graphite, 120g of conductive carbon black, and 72g of polytetrafluoroethylene solution, stir them in deion...

Embodiment 2

[0017] Prepare lithium strip positive electrode sheet 1 by the method described in embodiment 1, press figure 2 In the position shown, the length and width of the polymer tape sheet 4 are 25mm×4mm, and the length and width of the lithium strip negative electrode sheet are 240mm×25mm. The length of the groove for stopping the reaction is 25 mm, and the depth of the groove 5 accounts for 40% to 90% of the thickness of the entire negative electrode sheet. The width of the groove 5 accounts for 0.1%-7% of the length of the entire negative electrode sheet.

Embodiment 3

[0019] Prepare lithium strip positive electrode sheet 1 by the method described in embodiment 1, press figure 2 In the position shown, the length and width of the polymer tape sheet 4 are 30mm×8mm, and the length and width of the lithium strip negative electrode sheet are 240mm×25mm. The length of the groove for stopping the reaction is 25 mm, and the depth of the groove 5 accounts for 40% to 90% of the thickness of the entire negative electrode sheet. The width of the groove 5 accounts for 0.1%-7% of the length of the entire negative electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com