Working method of rubber wrapping device with air exhausting function used for cable processing

A working method and technology of functional packages, applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc., can solve the problem of cable processing consistency and quality can not be well guaranteed, component temperature rise, personnel operation complex, etc. Problems, achieve good cooling effect, increase production efficiency, and eliminate dust impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

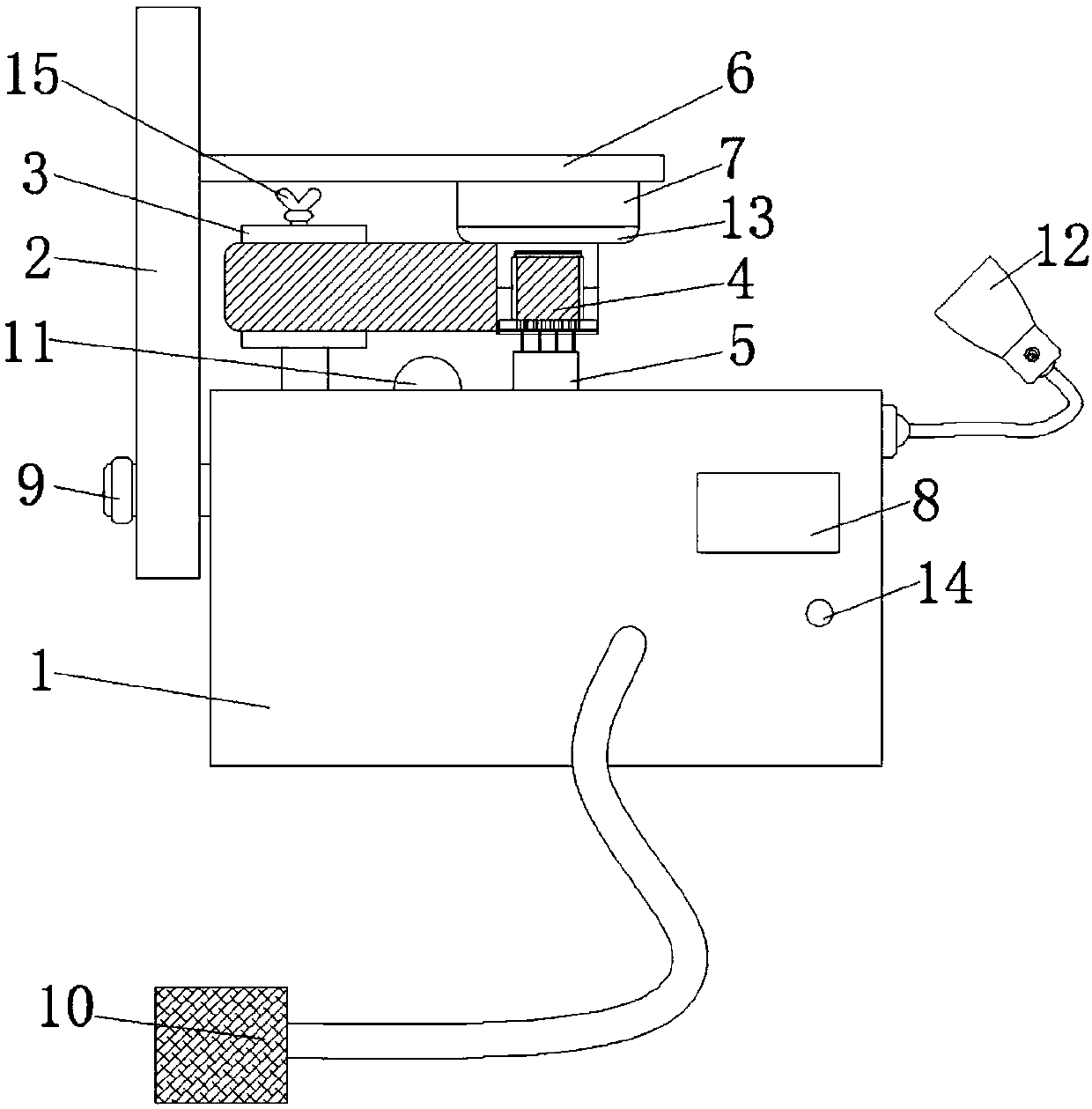

[0033] Such as figure 1 As shown, the working method of a cable processing rubber covering device with exhaust function in this embodiment, the specific working steps are as follows:

[0034](1) The staff first fix the cable on the corresponding fixture 4, and fix the matching tape fixing mechanism 3 on the frame 1, and then move the tape fixing mechanism 3, the rotating mechanism 5 and the pressing mechanism 7 back and forth to the proper location;

[0035] (2), the staff set the working parameters of the rotating mechanism 5 and the pressing mechanism 7 through the control panel 8, and turn on the power supply of the pedal 10 through the control panel 8;

[0036] (3) The staff drives the cylinder 2 by stepping on the pedal 10, and then the slide bar 6 drives the compression mechanism 7 to move downward, and the cable is fixed through the cooperation of the compression mechanism 7 and the jig 4;

[0037] (4), then the staff turns on the power supply of the rotating mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com