A liquid metal convective heat transfer coefficient detection device

A convective heat transfer coefficient and liquid metal technology, which is applied in the field of liquid metal convective heat transfer coefficient detection devices, can solve the problem of large measurement errors and difficult to solve the problem of heat soaking of convective heat exchange plates, convective heat exchangers and vacuum chamber heat spreaders Problems such as heat transfer difficulties, to solve corrosion problems and ensure the accuracy of experimental testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

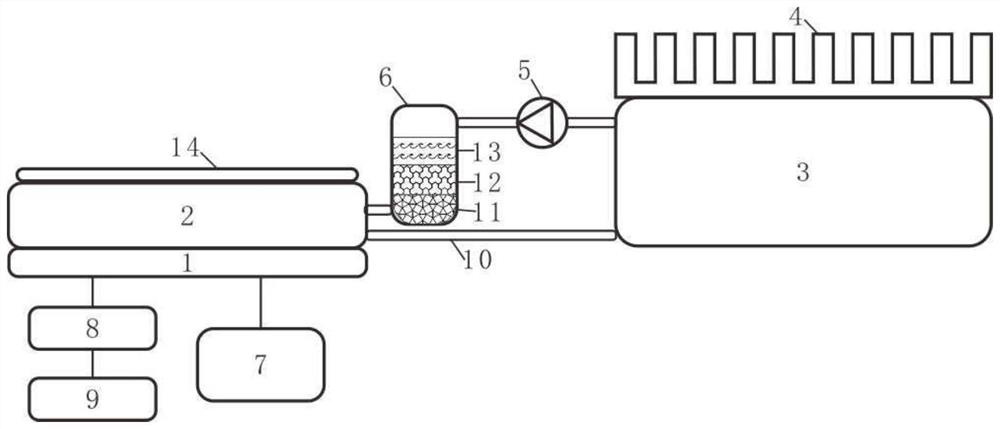

[0030] Embodiment 1 shows a typical application of the liquid metal convective heat transfer coefficient detection device of the present invention. figure 1 It is a structural schematic diagram of the liquid metal convective heat transfer coefficient detection device.

[0031] Such as figure 1 as shown,

[0032] In this embodiment, the liquid metal convective heat transfer coefficient detection device includes: a liquid metal circulation loop composed of a convective heat exchanger 2, a heat exchanger 3, a peristaltic pump 5 and a purifier 6 connected in sequence; the convective heat exchanger 2 The two independent sides are attached to the electric heating heat source 1 and the plate-type vacuum chamber heat spreader 14 respectively; the heat source 1 is provided with a temperature acquisition module 7 and a power meter 8 . Purifiers in the purifier 6 include liquid metal 11 , metasilicate solution 12 and vegetable oil 13 .

[0033]After the peristaltic pump 5 is started, ...

Embodiment 2

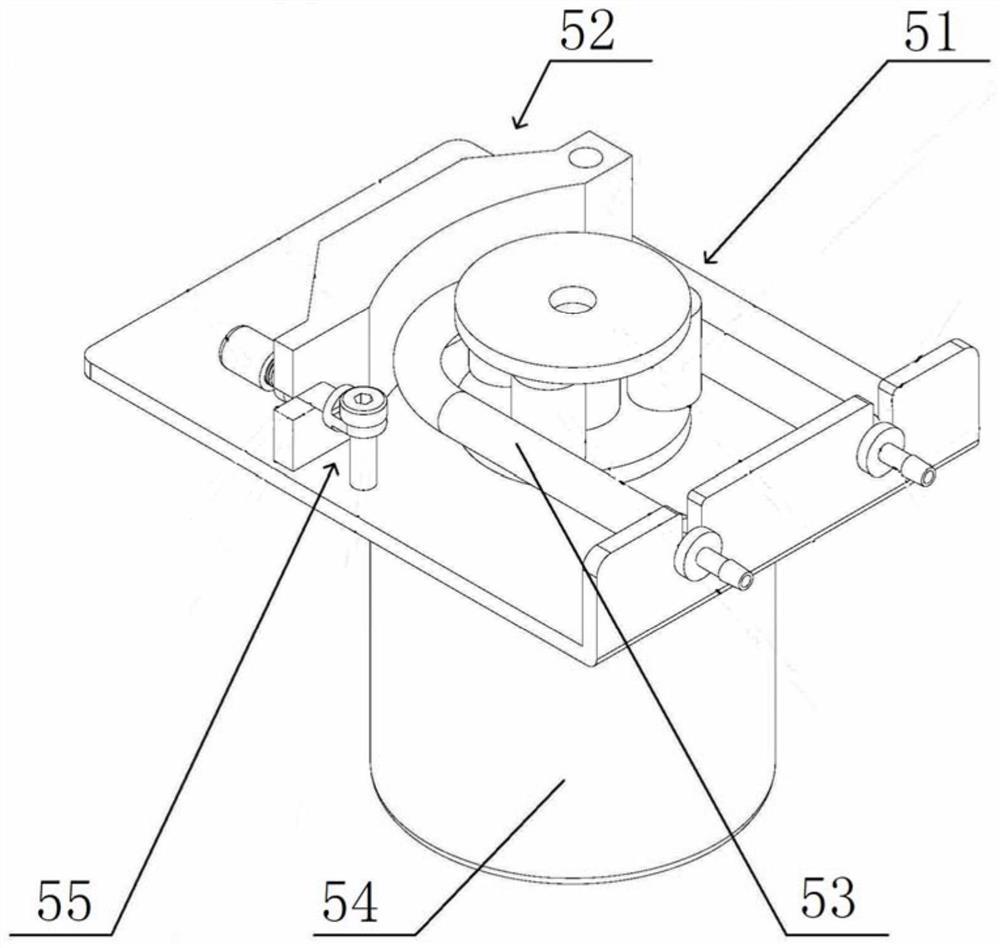

[0037] Example 2, such as figure 2 Shown is a schematic diagram of the structure of the peristaltic pump 5; the peristaltic pump 5 includes: a rotating extrusion part 51 provided with a main shaft and extrusion rollers, a stopper 52 provided with an upper cover and a base, a hose 53 and a driver 54 The driver 54 is arranged on the base of the limiting part 52, the output shaft of the driver 54 passes through the base and is connected to the main shaft of the rotating extrusion part 51; the main shaft is provided with the extruding roller, so The hose 53 is erected on the squeeze roller, and the hose 53 is fixed in position by the base of the limiting part 52. The upper cover of the limiting part 52 is buckled on the top of the hose 53, and the upper cover It is in contact with the base and fixed by the locking mechanism 55; when the peristaltic pump 5 is started, the output shaft of the driver 54 drives the rotation extrusion part 51 to rotate; the rotation extrusion part 51 ...

Embodiment 3

[0038] Example 3, the liquid metal 11 is gallium-indium-tin-zinc-bismuth aluminum alloy, and the amounts of each component are 63% gallium, 21% indium, 10% tin, 2% zinc, 3% bismuth, Aluminum 1%. According to the test of differential scanning calorimeter (Netzsch: DSC200F3), the melting point of the gallium indium tin zinc bismuth aluminum alloy is minus 5 degrees Celsius, which is lower than the current known low melting point alloy; the gallium indium tin zinc The heat capacity of bismuth aluminum alloy is 530J / Kg / K, which is higher than that of currently known low melting point alloys. Zinc gallate powder with a mass fraction of 0.01% is added to the liquid metal 11. Zinc gallate can strengthen the supercooling degree of the liquid metal at low temperature, so that the liquid metal is not easy to crystallize at low temperature, so it can be measured in a lower temperature range. The liquid metal convective heat transfer coefficient.

[0039] The vacuum chamber vapor chambe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com