Test module, system and test method for testing damping valve of oil damper

A technology of testing modules and damping valves, which is applied in the testing of machines/structural components, shock absorbers, mechanical valves, etc., which can solve problems such as inconvenient, infeasible, and non-energy-saving, and achieve convenient and accurate movement and management of equipment Effect of test temperature and accurate temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

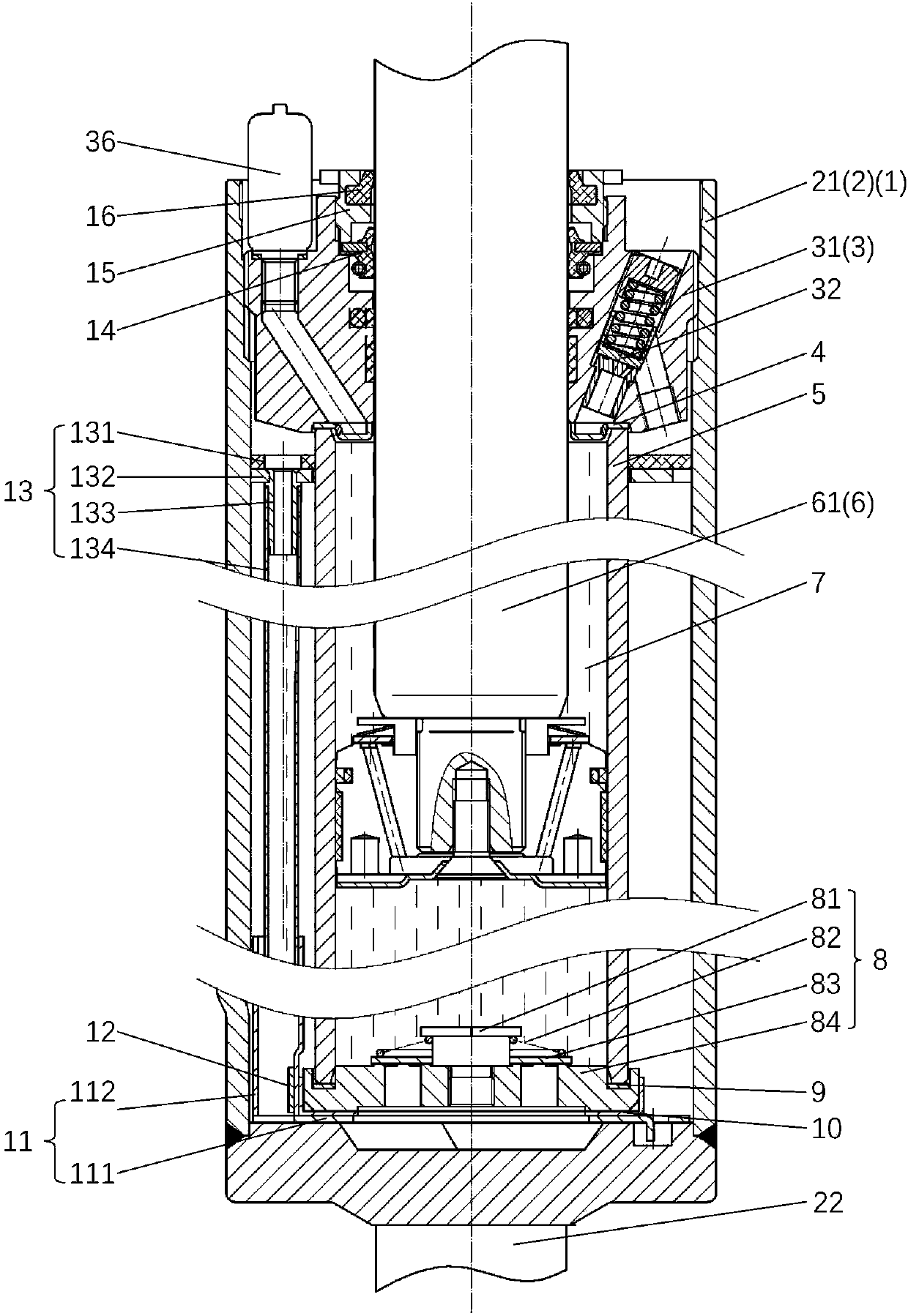

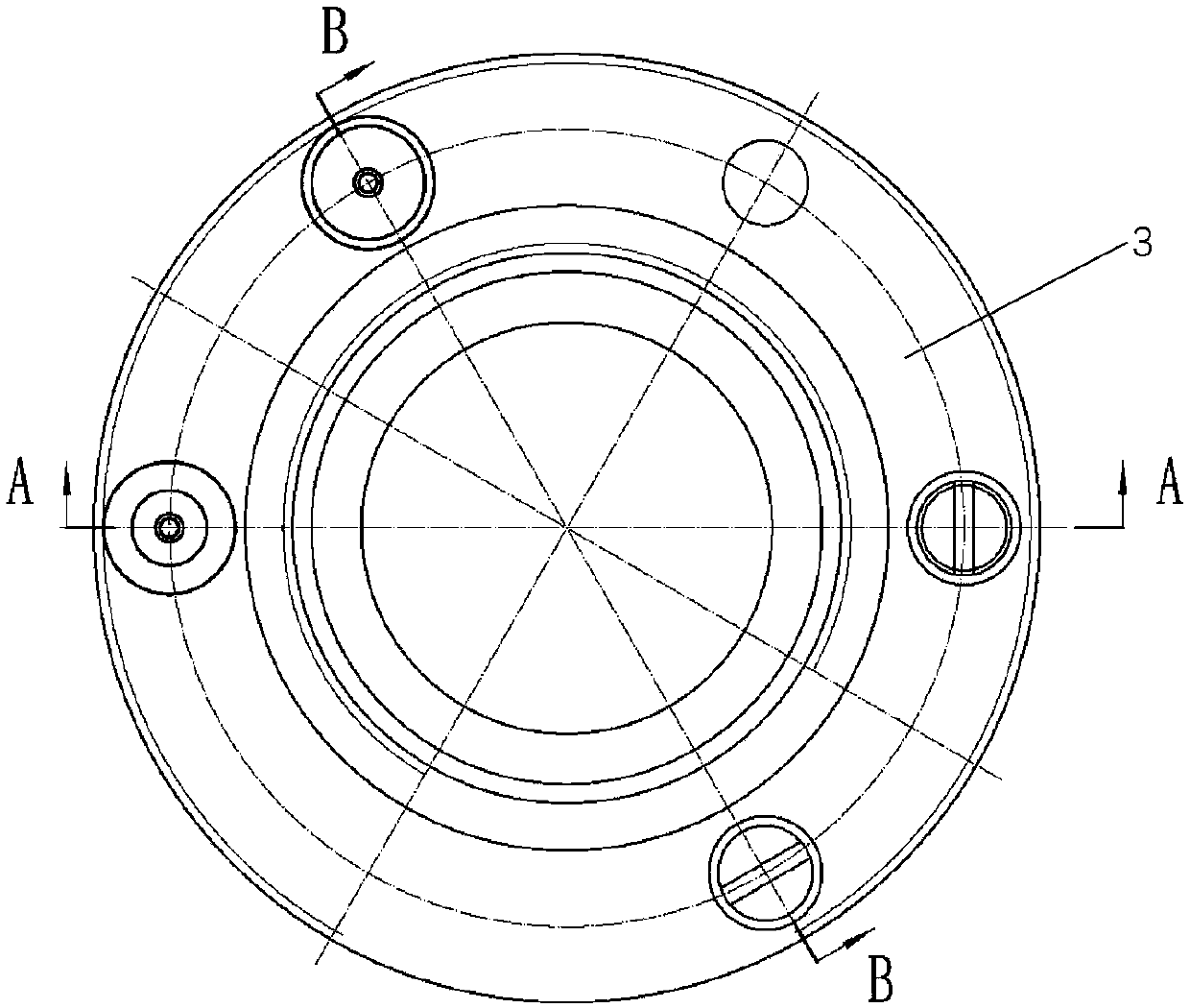

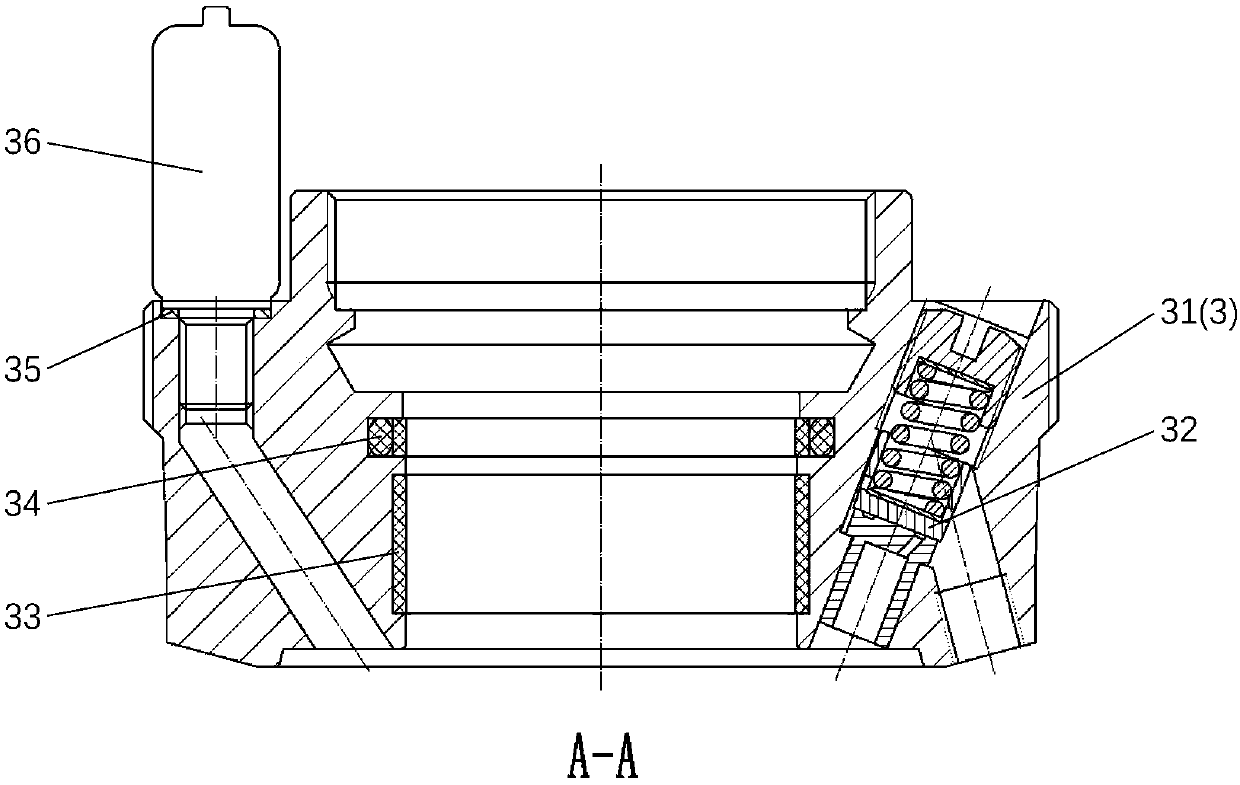

[0049] Figure 1 to Figure 8 It shows an embodiment of a testing module of the present invention for testing the dynamic characteristics of a damper valve of an oil pressure shock absorber. The test module includes oil storage cylinder assembly 2, guide assembly 3, guide exhaust plate 4, pressure cylinder 5, piston-piston rod assembly 6, hydraulic oil 7, bottom valve assembly 8, pressure cylinder gasket 9, bottom Valve gasket 10, oil guide plate assembly 11, magnet 12, oil return assembly 13, skeleton oil seal 14, screw cap 15 and dustproof ring 16. The oil deflector assembly 3 is connected to the oil storage cylinder assembly 2, the oil deflector assembly 3 is placed at the bottom of the cylinder barrel of the oil storage cylinder assembly 2, the bottom valve gasket 10 is placed on the base of the oil deflector assembly 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com