Gas stove with lifting type dry-boiling prevention temperature sensors and control method thereof

A technology of temperature sensor and gas cooker, which is applied in the control of the above-mentioned gas cooker and the field of gas cooker, can solve the problems of small contact pressure, small contact area, prone to skewed contact between the temperature sensor and the bottom of the pot, etc., and achieve simple control, The effect of the simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

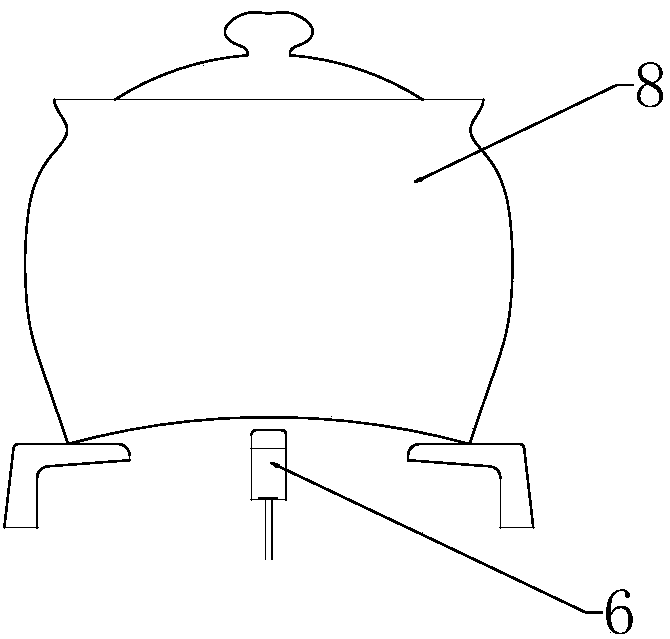

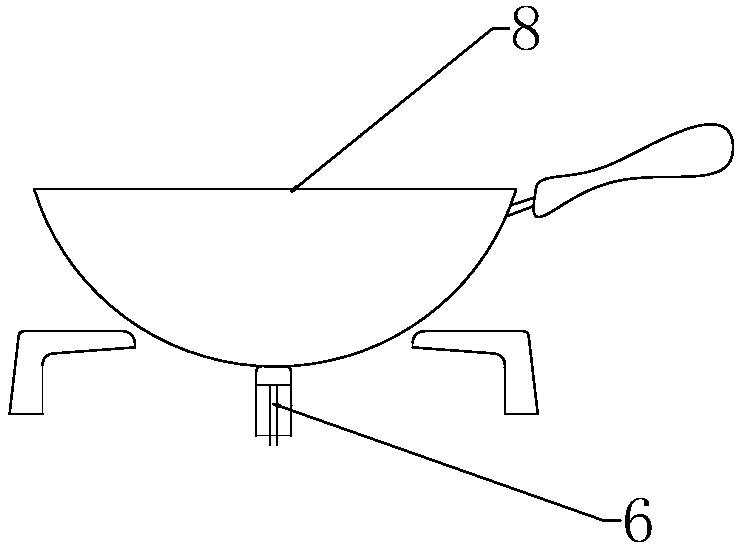

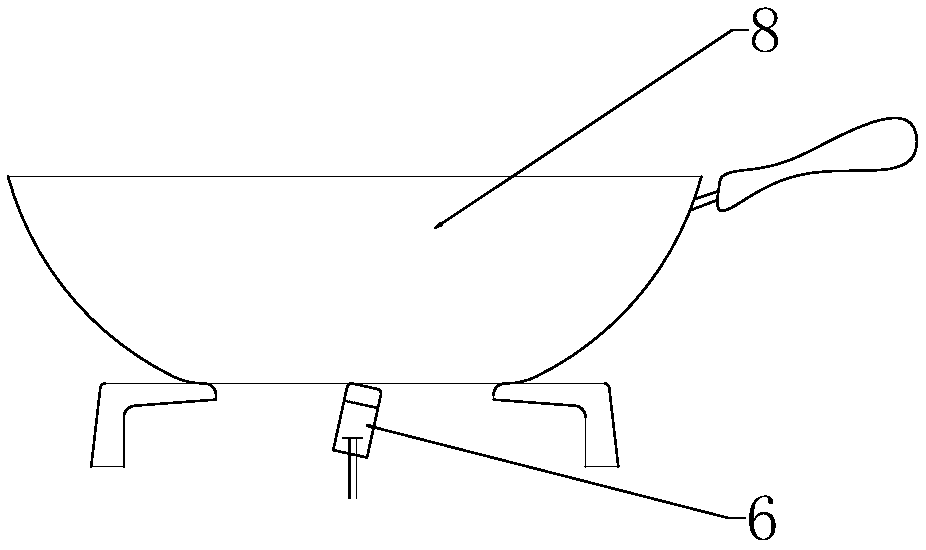

[0052] Figure 4 to Figure 11 A preferred embodiment of a gas cooker with a lift-type anti-dry heating temperature sensor according to the present invention is shown. As shown in the figure, the gas stove includes a panel 3, a burner 2, a pot support 1, and the burner 2 also includes a fire cover with a central through hole and a temperature sensor 6 arranged in the central through hole of the fire cover. Wherein the fire cover can be one circle or multiple circles (single or multiple). The gas cooker also includes a lift mechanism 7 connected with the temperature sensor 6 for driving the temperature sensor up and down, and a control system connected with the lift mechanism 7 for controlling the lift of the temperature sensor 6 . When the gas cooker is not working, the temperature sensor 6 can be lowered into the inside of the cooker through the central through hole of the fire cover through the lifting mechanism under the control of the control system, such as Figure 7 sho...

Embodiment 2

[0093] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

[0094] Such as Figure 12 with Figure 13As shown, the judging device includes a limit switch 65 arranged on the inner tube 61, and a sensitive block 68 is arranged on the wire 67. When the elastic element 64 reaches a predetermined amount of compression, the sensitive block 68 on the wire 67 and the limit switch 68 Correspondingly, and trigger the limit switch 68. That is to say, when the lifting mechanism 7 drives the temperature sensor 6 to rise and fall, the limit switch 68 rises and falls together with the temperature sensor 6, and when the temperature sensor 6 touches the pot 8 during the rising process, the outer end cover stops rising, and the inner pipe 61 As it continues to rise, th...

Embodiment 3

[0106] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

[0107] Such as Figure 15 As shown, the lifting mechanism 7C includes a fixed bracket 7C-1 for fixing the temperature sensor 6, a cam 7C-2 and a support frame 7C-5 for supporting the cam 7C-2, the fixed bracket 7C-1 includes a fixed bracket body, One side of the fixed bracket body is provided with a transverse chute 7C-8, and the free end of the cam 7C-2 is slidably connected with the transverse chute 7C-8.

[0108] During use, the cam 7C-2 is rotated, and the fixed bracket 7C-1 cooperating with the cam 7C-2 is driven to move up and down under the rotation of the cam 7C-2, thereby driving the temperature sensor 6 connected with the fixed bracket 7C-1 to move up and down, so , the lifting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com