Device for efficiently getting water, eliminating white smoke and cooperatively removing contaminants and working method for device

A pollutant and white smoke technology, applied in the field of efficient water intake and white smoke collaborative pollutant removal device, can solve the problems of chimney internal corrosion, white "smoke plume pollution, waste of water resources, etc., to reduce the level of anti-corrosion, Whitening phenomenon, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

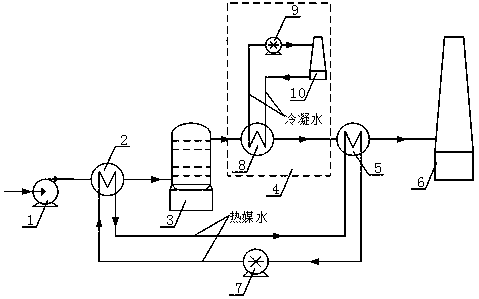

[0037] see figure 1 ,3-7.

[0038] This embodiment is a high-efficiency water intake and white smoke elimination collaborative pollutant removal device, including induced draft fan 1, deep waste heat recovery system 2, desulfurization system 3, high-efficiency condensation water intake system 4, flue gas reheating and white smoke elimination system 5, and a chimney 6 and heat medium water circulation pump 7. The high-efficiency condensate water intake system 4 includes a condensate water intake heat exchange system 8 , a condensate water circulation pump 9 and a mechanical ventilation cooling tower 10 .

[0039]Induced fan 1, deep waste heat recovery system 2, desulfurization system 3, high-efficiency condensation water intake system 4, flue gas reheating and white smoke elimination system 5 and chimney 6 are arranged in sequence along the flue gas flow direction, induced draft fan 1 and deep waste heat recovery system 2 Connection, the deep waste heat recovery system 2 is a...

Embodiment 2

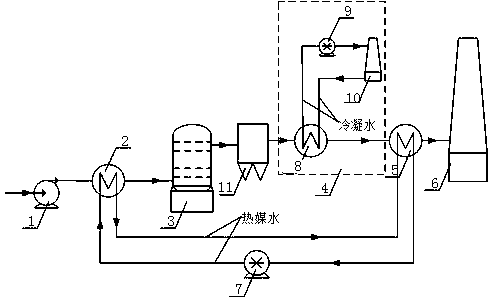

[0057] see Figure 2-7 .

[0058] This embodiment is a high-efficiency water intake and white smoke collaborative pollutant removal device, including a wet electrostatic precipitator system 11, an induced draft fan 1, a deep waste heat recovery system 2, a desulfurization system 3, a high-efficiency condensation water intake system 4, and flue gas reheating White smoke elimination system 5, chimney 6 and heat medium water circulation pump 7. The high-efficiency condensate water intake system 4 includes a condensate water intake heat exchange system 8 , a condensate water circulation pump 9 and a mechanical ventilation cooling tower 10 .

[0059] Induced fan 1, deep waste heat recovery system 2, desulfurization system 3, wet electrostatic precipitator system 11, high-efficiency condensation water intake system 4, flue gas reheating and white smoke elimination system 5 and chimney 6 are arranged in sequence along the flue gas flow direction, and the induced draft fan 1 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com