A method for reducing the breakage rate of quartz tubes during the preparation of scintillation single crystals

A preparation process and technology of quartz tubes, which are applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem that the volume of scintillation crystal materials changes with temperature, the expansion coefficient of scintillation crystal materials is low, and the expansion coefficient of quartz tubes is small. and other problems, to achieve the effect of reducing the risk of crystal cracking, reducing the probability of self-absorption, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

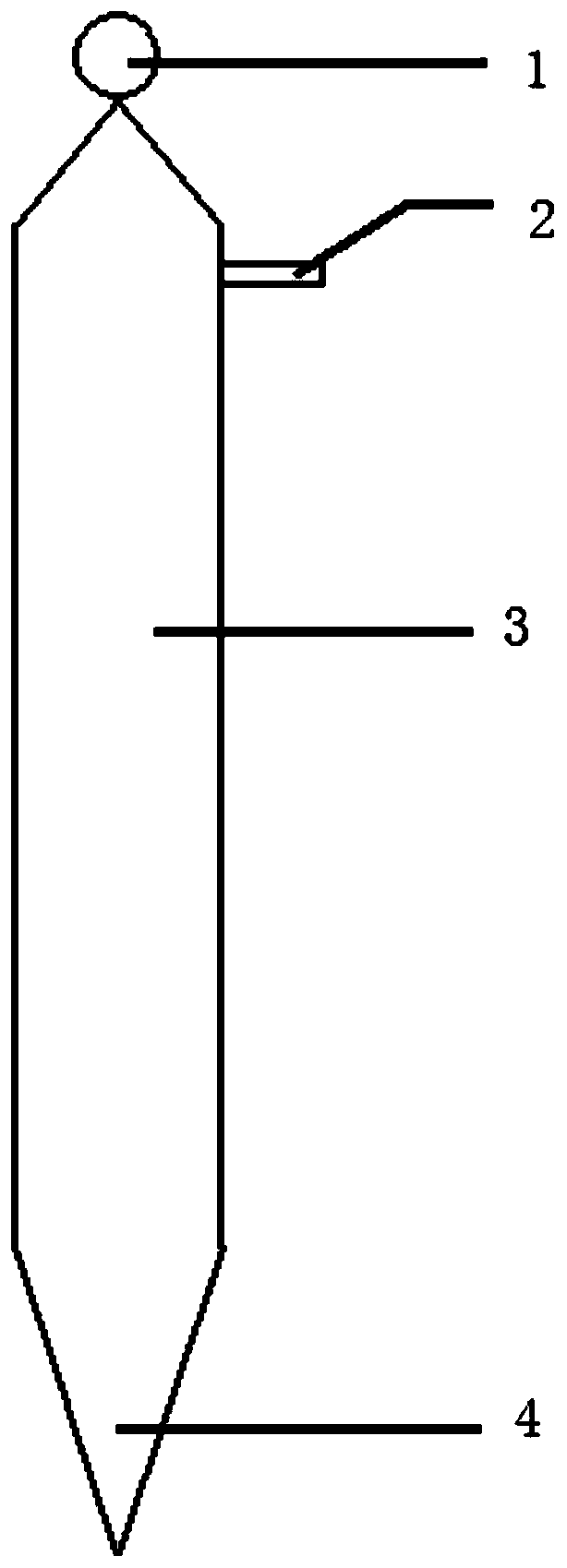

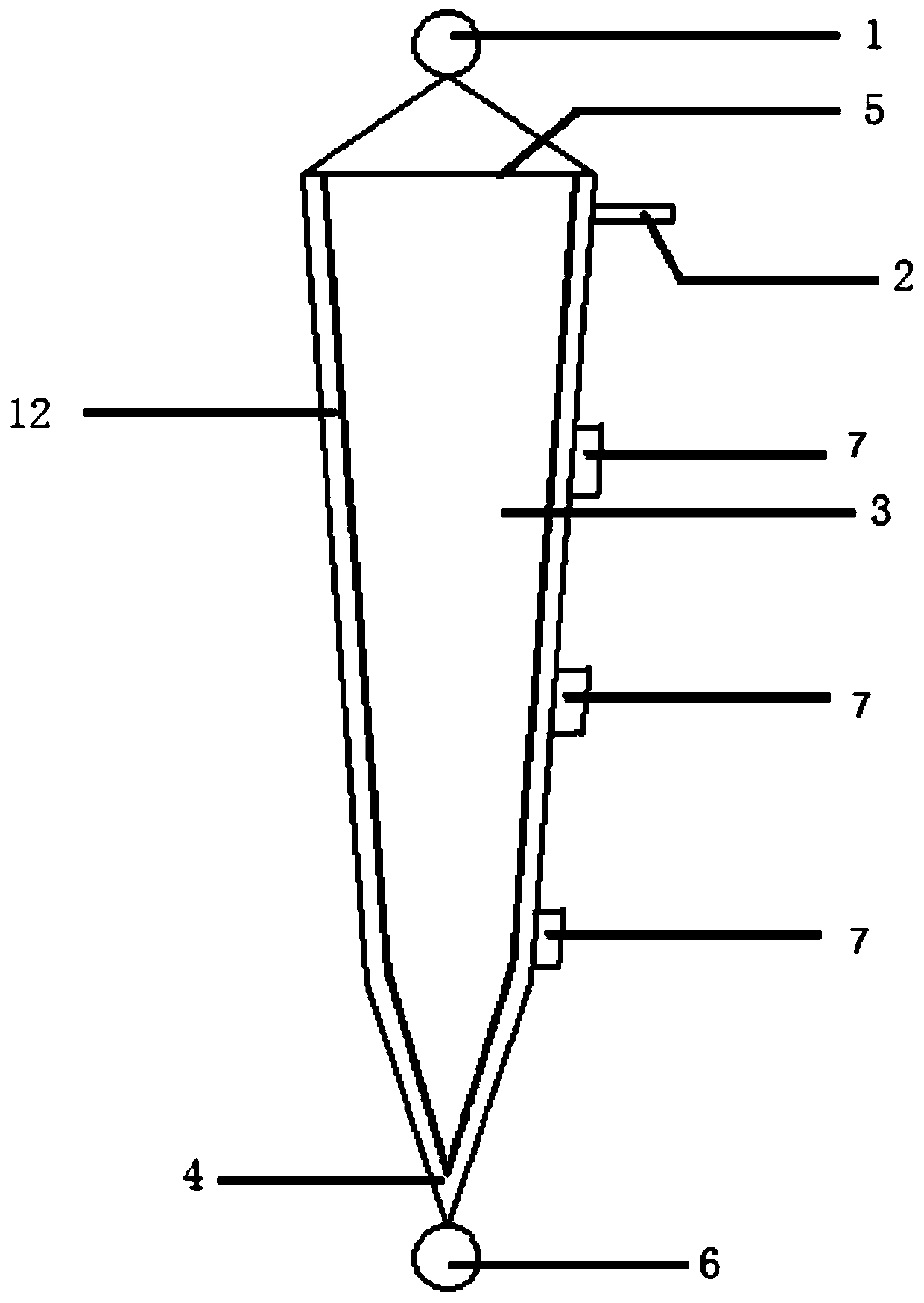

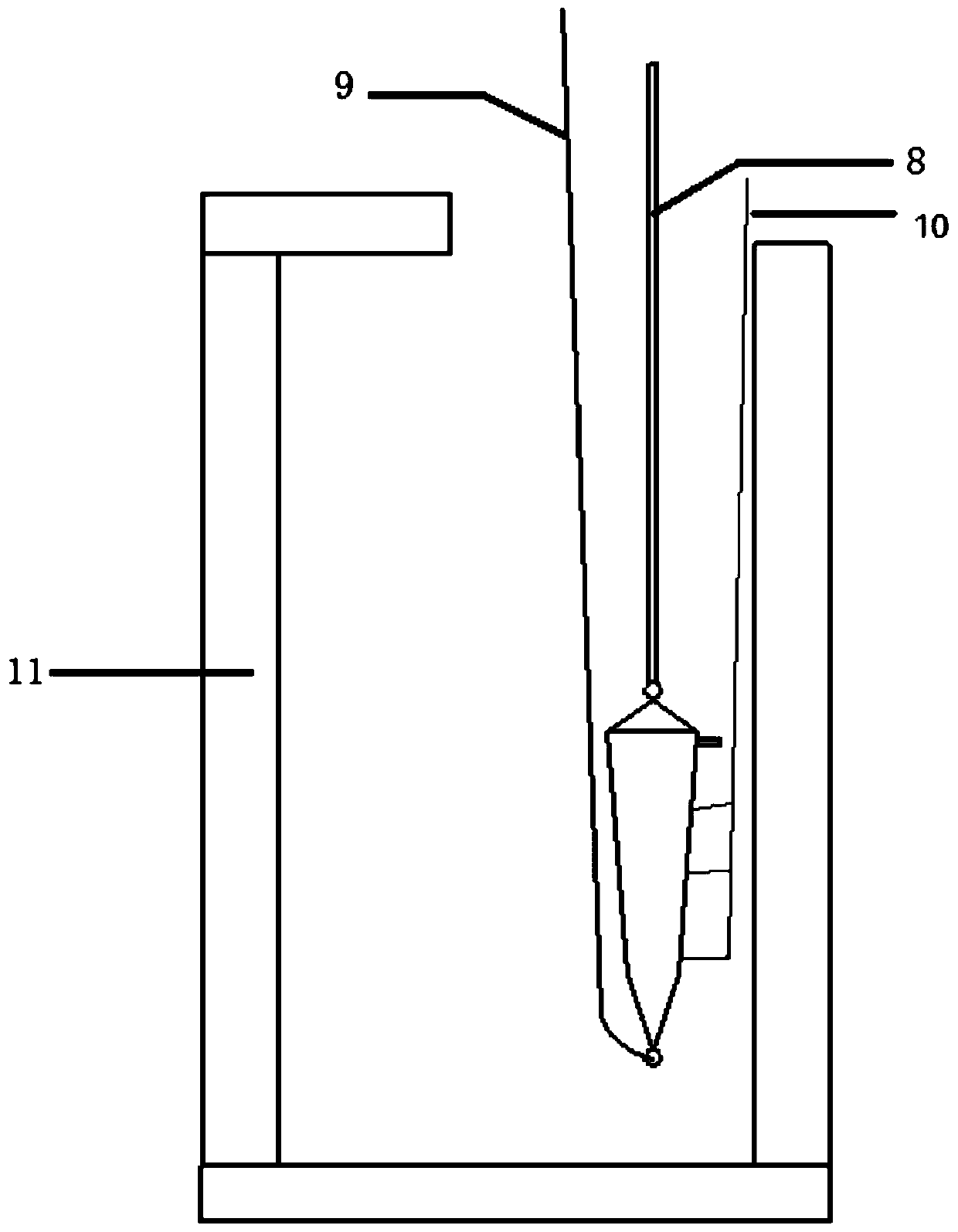

[0040] figure 2 It is a schematic diagram of the special-shaped quartz tube adopted in the present invention, image 3 It is a schematic diagram of the arrangement of quartz tubes in a single crystal furnace.

[0041] Take sodium iodide doped indium (NaI:In) scintillation single crystal material as an example:

[0042] (1) Quartz tube drawing

[0043] Choose a quartz tube with no defects and a smooth inner wall, wash it repeatedly with deionized water, dry it, and heat it to 1900-2000°C with an oxygen-hydrogen flame to soften the quartz tube, and draw it into a special-shaped quartz tube with a thick top and a thin bottom;

[0044] (2) Inner wall coating of special-shaped quartz tube

[0045] The above-mentioned special-shaped quartz tube is repeatedly washed with deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com