Single-layer graphene/aluminum composite material and preparation method thereof

A technology of single-layer graphene and aluminum composite materials, applied in the direction of conductive materials, conductive materials, metal/alloy conductors, etc., can solve the problems that the expected effect of uniform dispersion is not achieved, the comprehensive performance of composite materials is not obvious, and the cost is low , Reasonable composition ratio and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

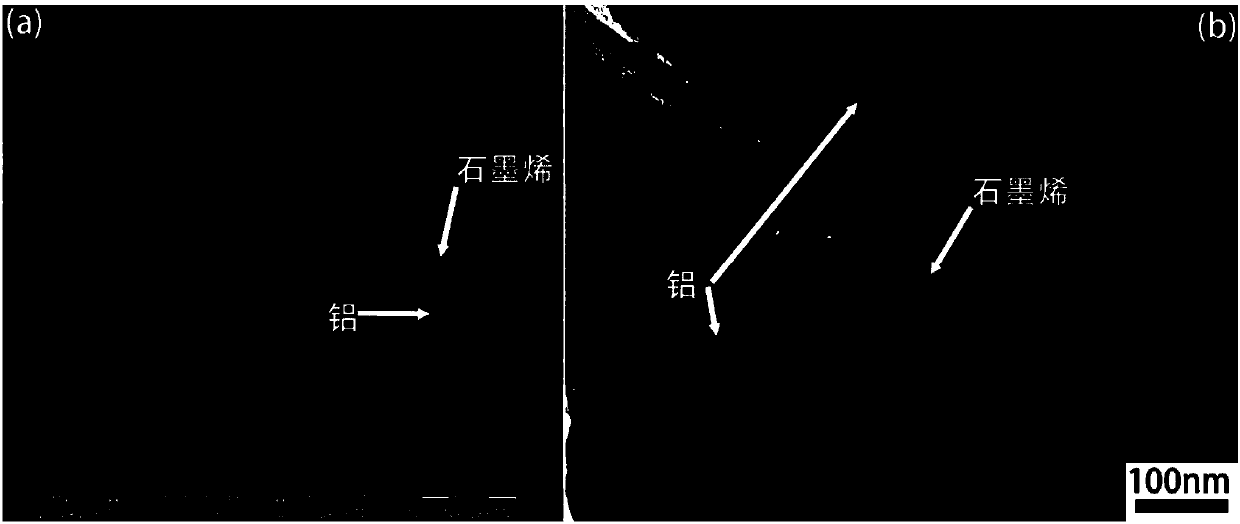

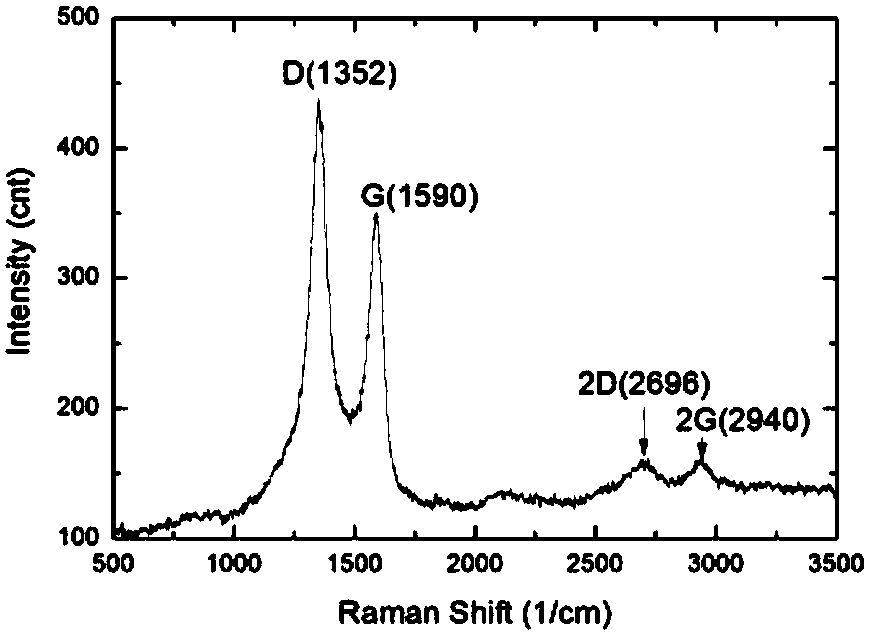

Image

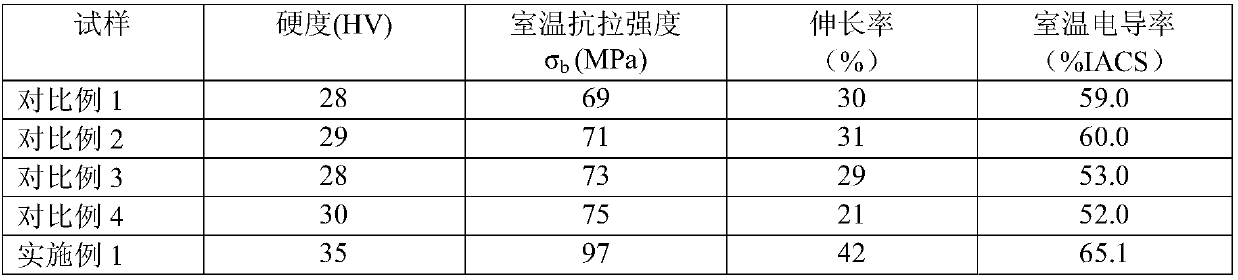

Examples

Embodiment 1

[0032] It is 0.1% graphene / aluminum composite material to prepare graphene dosage, and preparation method is: 1) prepare mass fraction concentration by ultrasonic dispersion method and be 0.5% monolayer graphene alcohol dispersion; 2) by mass fraction 0.5% graphene : the ratio of 99.5% superfine aluminum powder, the purity of pure aluminum powder is 99.9%, and the number of orders is 600 orders. Pure aluminum powder is added in the single-layer graphene alcohol dispersion in step 1), and under argon protection Lower the ball mill and mix for 6 hours, the ball mill speed is 200r / min, and then dry in a vacuum oven at 50°C to obtain a single-layer graphene / aluminum composite powder; 3) Pass the single-layer graphene / aluminum composite powder in step 2) through Prepare the preform by spark plasma sintering, the sintering temperature is 400°C, the sintering time is 5min, and the axial pressure is 5MPa; 4) Melt the pure aluminum at a temperature of 720°C, and degas and remove slag; 5...

Embodiment 2

[0035]It is 0.2% graphene / aluminum composite material to prepare graphene dosage, and preparation method is: 1) prepare the single-layer graphene alcohol dispersion liquid that mass fraction concentration is 1% by ultrasonic dispersion method; 2) by mass fraction 1% graphite Graphene: the ratio of 99% ultrafine aluminum powder, the pure aluminum powder is 600 mesh, the pure aluminum powder is added to the single-layer graphene alcohol dispersion in step 1), and ball milled and mixed for 12h under the protection of argon, ball milled The rotation speed is 400r / min, and then dried in a vacuum drying oven at 80°C to obtain a single-layer graphene / aluminum composite powder; 3) The single-layer graphene / aluminum composite powder in step 2 is prepared into a prefabricated body by spark plasma sintering , the sintering temperature is 500°C, the sintering time is 10min, and the axial pressure is 20MPa; 4) Melt pure Al at a temperature of 740°C, and remove gas and slag; 5) At a stirring...

Embodiment 3

[0038] Prepare the graphene / aluminum alloy composite material that the graphene dosage is 0.1%, the aluminum alloy is Al-0.05Si-0.03Cu-0.02Fe, the composite material preparation method is: 1) prepare mass fraction concentration by ultrasonic dispersion method and be 1% Single-layer graphene alcohol dispersion; 2) by mass fraction 1% graphene: 99% ultra-fine aluminum powder ratio, pure aluminum powder is 600 orders, pure aluminum powder is added to the single-layer graphene alcohol in step 1) Dispersion liquid, and ball milling and mixing for 12h under the protection of argon, the ball milling speed is 400r / min, and then drying in a vacuum oven at 80°C to obtain a single-layer graphene / aluminum composite powder; 3) the single-layer graphene / aluminum composite powder in step 2) Layer graphene / aluminum composite powder is prepared into a preform by spark plasma sintering, the sintering temperature is 500°C, the sintering time is 10min, and the axial pressure is 20MPa; 4) The alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com