Method for utilizing microchannel reactor for synthesizing Nintedanib intermediate

A technology of microchannel reactor and nintedanib, which is applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc., can solve the problem of low frequency of catalyst recycling and easy occurrence Problems such as violent explosion and long reaction time, etc., to achieve the effect of easy realization of automatic control, economical production guarantee and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

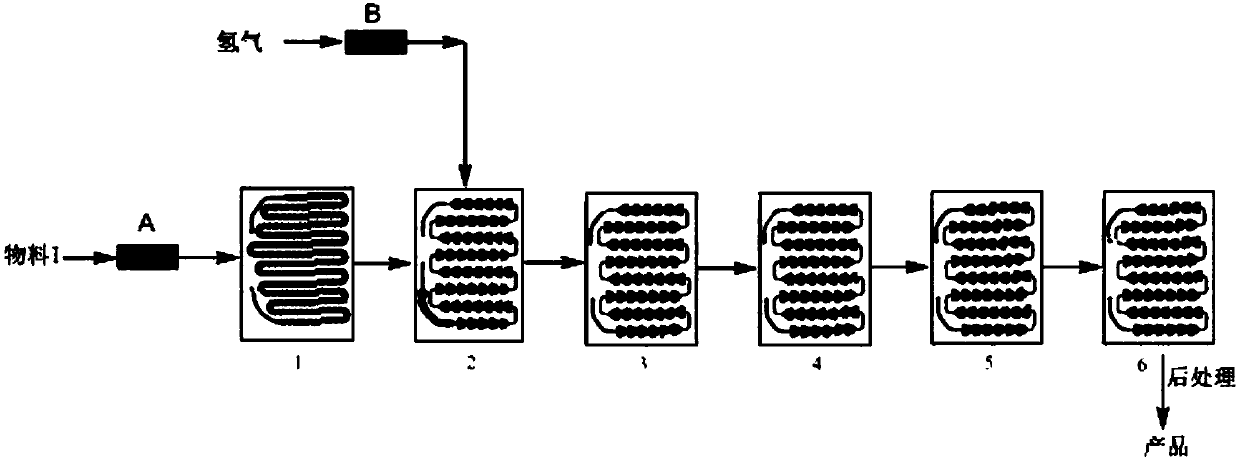

[0042] This embodiment provides a method for synthesizing nintedanib intermediate using a microchannel reactor, and the synthesis method is as follows:

[0043] 1) Weigh 150g of N-(4-nitrophenyl)-N,4-dimethyl-1-piperazineacetamide and add 3L of anhydrous methanol, stir evenly, add 5g of 10% Pd / C, stir well Mix to form material I, and transport material I to the preheating module of the microchannel reactor for preheating;

[0044] 2) Hydrogen is directly delivered to the reaction module group of the microchannel reactor, and the reduction hydrogenation reaction is carried out with the preheated material I in the reaction module group, wherein: the flow rate of the slurry pump is adjusted so that the flow rate of the material I is 30.0g / min, adjust H 2 The flow rate of the gas flow meter is 450ml / min, the reduction hydrogenation reaction temperature is 100°C, and the nitro compound of the nintedanib intermediate is mixed with H 2 The molar ratio is 1:3.5, the total residence ...

Embodiment 2

[0046] This embodiment provides a method for synthesizing nintedanib intermediate using a microchannel reactor, and the synthesis method is as follows:

[0047] 1) Weigh 200g of N-(4-nitrophenyl)-N,4-dimethyl-1-piperazineacetamide and add 4L of absolute ethanol, stir evenly, add 6g of 10% Pd / C, stir well Mix to form material I, and transport material I to the preheating module of the microchannel reactor for preheating;

[0048] 2) Hydrogen is directly delivered to the reaction module group of the microchannel reactor, and the reduction hydrogenation reaction is carried out with the preheated material I in the reaction module group, wherein: the flow rate of the slurry pump is adjusted so that the flow rate of the material I is 35.0g / min, adjust H 2 The flow rate of the gas flow meter is 500ml / min, the reduction hydrogenation reaction temperature is 90°C, and the nitro compound of the nintedanib intermediate is mixed with H 2 The molar ratio is 1:3.4, the total residence tim...

Embodiment 3

[0050] This embodiment provides a method for synthesizing nintedanib intermediate using a microchannel reactor, and the synthesis method is as follows:

[0051] 1) Weigh 180g of N-(4-nitrophenyl)-N,4-dimethyl-1-piperazineacetamide and add 3.6L of anhydrous methanol, stir evenly, add 5g of 10% Pd / C, fully Stir and mix to form material I, and transport material I to the preheating module of the microchannel reactor for preheating;

[0052] 2) Hydrogen is directly delivered to the reaction module group of the microchannel reactor, and the reduction hydrogenation reaction is carried out with the preheated material I in the reaction module group, wherein: the flow rate of the slurry pump is adjusted so that the flow rate of the material I is 35.0g / min, adjust H 2 The flow rate of the gas flow meter is 600ml / min, the reduction hydrogenation reaction temperature is 100°C, and the nitro compound of the nintedanib intermediate is mixed with H 2 The molar ratio is 1:3.5, the total res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com