Method for removing acetanilide in wastewater

A technology of acetanilide and waste water, applied in chemical instruments and methods, water pollutants, neutralization water/sewage treatment and other directions, can solve the problems of complex catalytic oxidation equipment, high catalyst cost, unfavorable industrial waste water treatment and wide application, etc. There is no secondary pollution problem and the effect of improving biodegradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

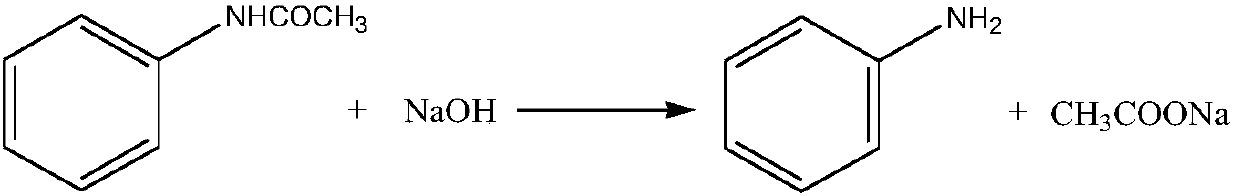

Method used

Image

Examples

Embodiment 1

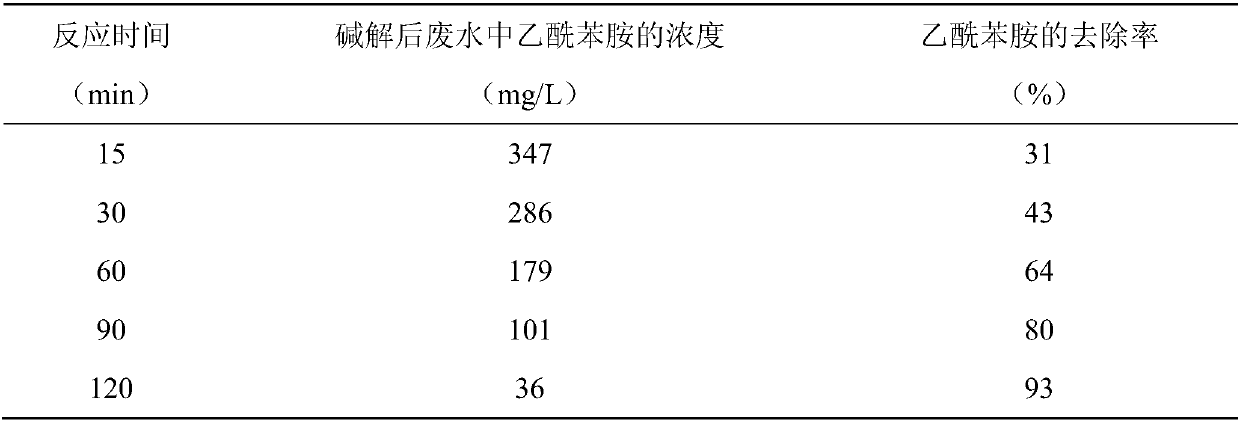

[0025] Acetanilide (analytical pure) and distilled water were used to prepare simulated wastewater containing acetanilide, wherein the concentration of acetanilide was 500mg / L. Take several parts of simulated wastewater with a volume of 100mL and place them in different 250mL conical flasks, and use solid sodium hydroxide (analytical pure) to dilute the OH of the wastewater - The concentrations were all adjusted to 0.5mol / L. Then, they were all reacted in a water bath at 90°C for 15-120 minutes, and one of the water samples was taken at regular intervals, and finally the pH value of the water sample was adjusted to about 7 with concentrated sulfuric acid. The results are shown in Table 1.

[0026] Table 1

[0027]

[0028] It can be seen from Table 1 that when high-temperature alkaline hydrolysis is used to treat simulated wastewater containing acetanilide, the reaction time has a greater impact on the removal rate of acetanilide by alkaline hydrolysis. When the reaction ...

Embodiment 2

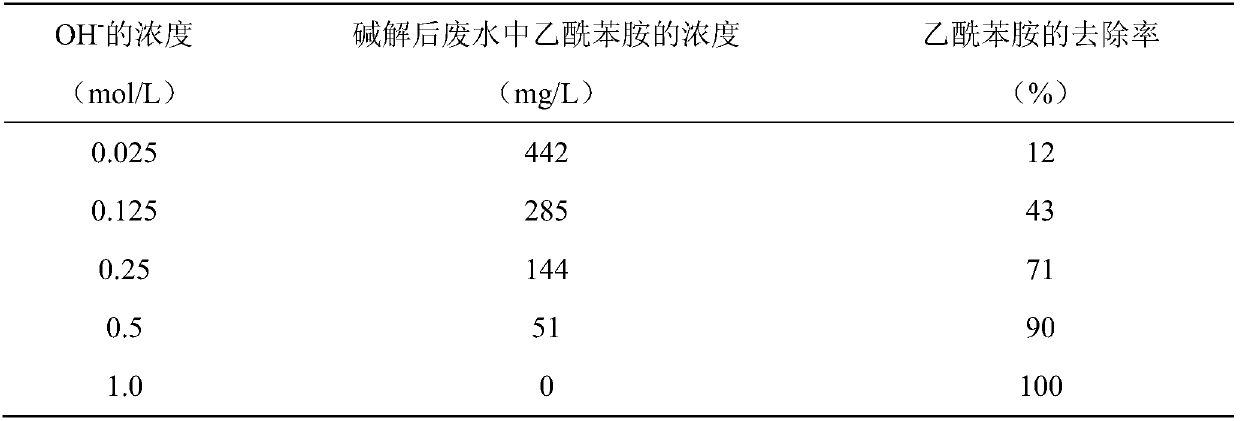

[0030] Acetanilide (analytical pure) and distilled water were used to prepare simulated wastewater containing acetanilide, wherein the concentration of acetanilide was 500mg / L. Take several parts of simulated wastewater with a volume of 100mL and place them in different 250mL Erlenmeyer flasks. Add different amounts of solid sodium hydroxide (analytical pure) to these several parts of simulated wastewater, and then place them in a water bath at 90°C. After reacting for 2 hours, the pH value of the water sample was adjusted to about 7 with concentrated sulfuric acid. The results are shown in Table 2.

[0031] Table 2

[0032]

[0033] It can be seen from Table 2 that when high-temperature alkaline hydrolysis is used to treat simulated wastewater containing acetanilide, as the alkaline hydrolysis system OH - With the increase of concentration, the alkaline hydrolysis removal rate of acetanilide in wastewater gradually increased, but the alkaline hydrolysis rate gradually dec...

Embodiment 3

[0035] Acetanilide (analytical pure) and distilled water were used to prepare simulated wastewater containing acetanilide, wherein the concentration of acetanilide was 500mg / L. Take several parts of simulated wastewater with a volume of 100mL and place them in different 250mL conical flasks, and use solid sodium hydroxide (analytical pure) to dilute the OH of the wastewater - The concentrations were all adjusted to 0.5mol / L. Then alkaline hydrolysis was carried out at room temperature (20°C) and in a water bath at 50°C to 100°C for 2 hours, and finally the pH value of the water sample was adjusted to about 7 with concentrated sulfuric acid. The results are shown in Table 3.

[0036] table 3

[0037]

[0038] It can be seen from Table 3 that when high-temperature alkaline hydrolysis is used to treat simulated wastewater containing acetanilide, as the reaction temperature increases, the alkaline hydrolysis removal rate of acetanilide in wastewater increases gradually, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com