Cross hole burr removing equipment

A burr removal and burr technology, used in metal processing equipment, abrasives, manufacturing tools, etc., can solve problems such as surface tarnishing and affect dimensional accuracy, and achieve the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

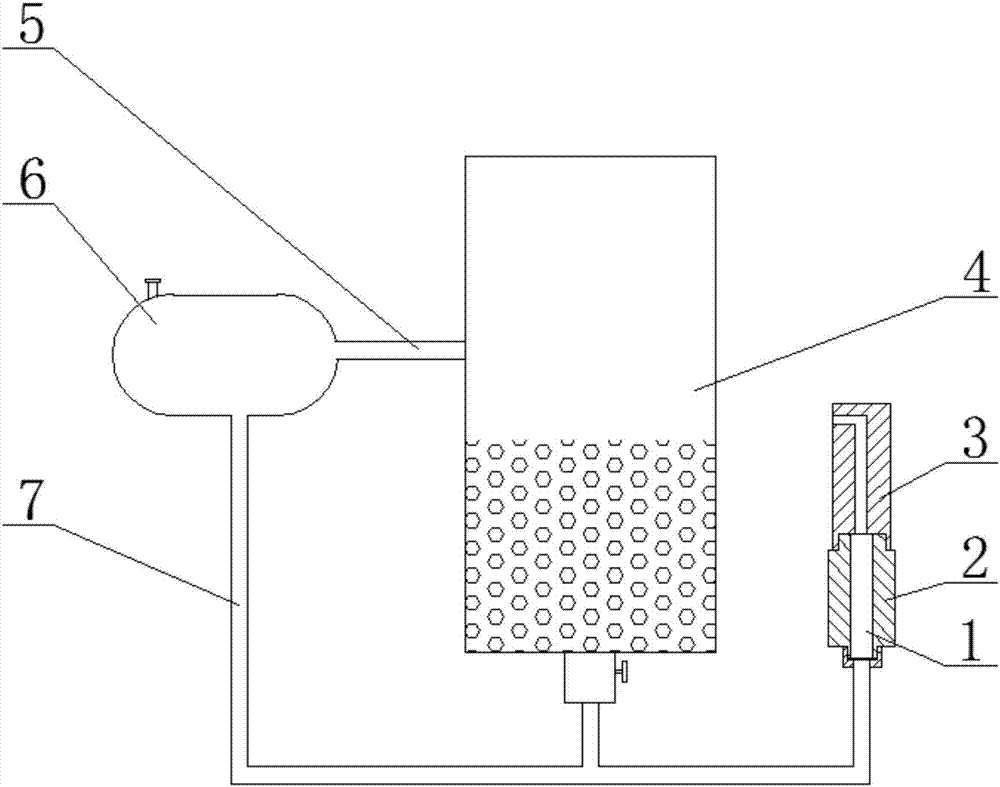

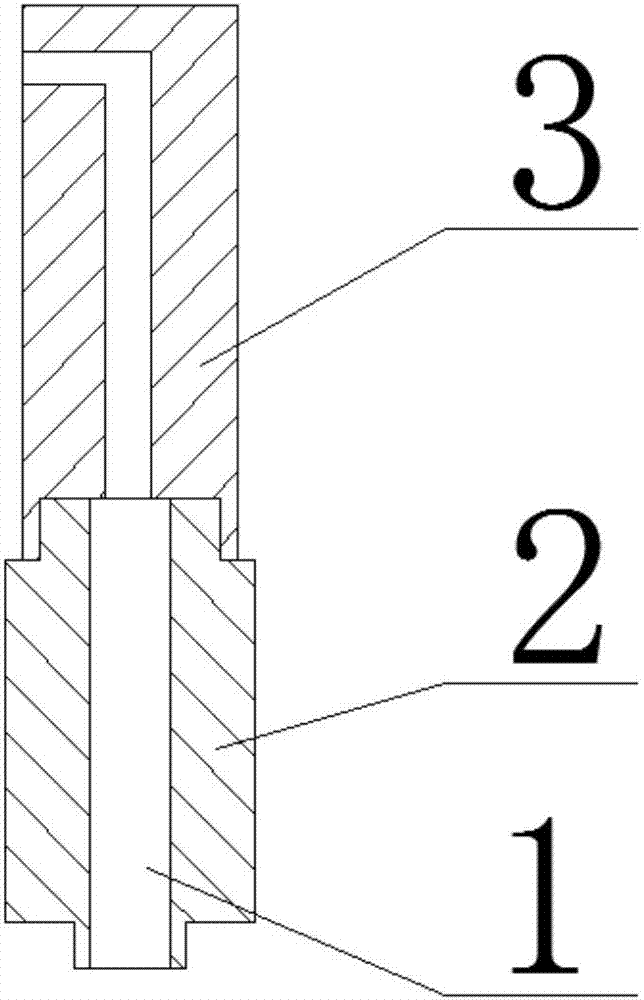

[0034] According to the drawings, this embodiment provides a cross-hole burr removal device, including a burr removal assembly 1, an abrasive cylinder 4, an abrasive cylinder pressurized intake pipe 5, an air compressor 6, and a compressed air discharge pipe 7. The burr The removal assembly 1 is threadedly connected with the compressed air discharge pipe 7, which is convenient for disassembly and has good sealing performance; Disassembly can also withstand higher air pressure, and the sealing performance is good; the air compressor 6 is flange-connected with the abrasive cylinder pressurized intake pipe 5 and the compressed air discharge pipe 7, which is easy to disassemble and can withstand high air pressure. Air pressure, and good sealing.

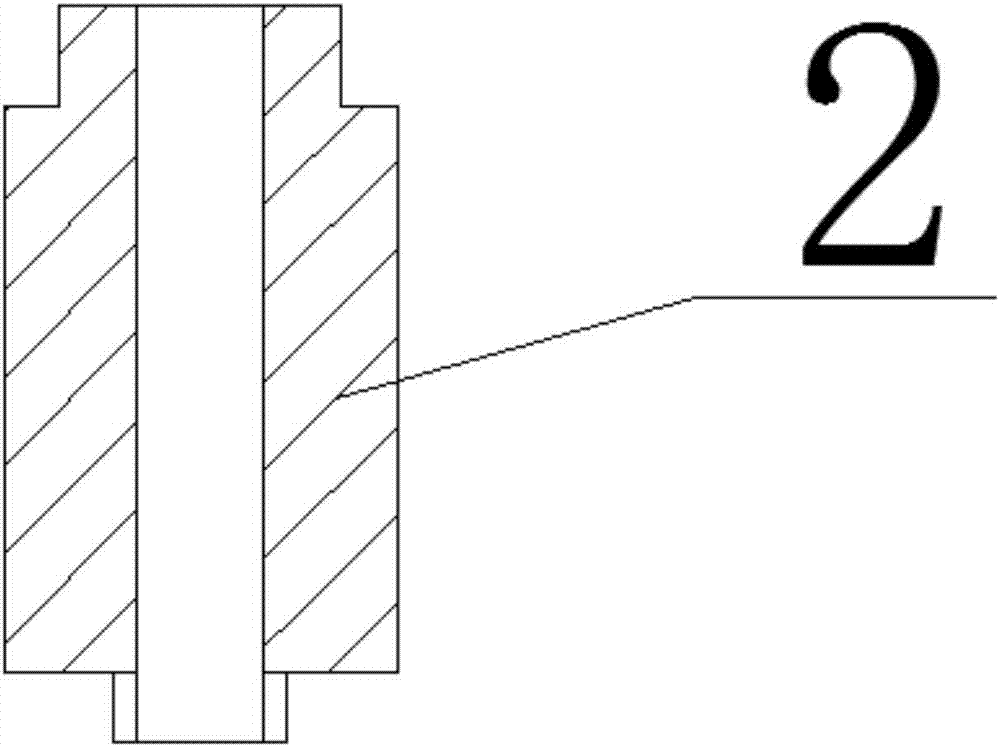

[0035] The deburring assembly 1 includes a sandblasting joint 2 and a guide rod 3 , and the guide rod 3 is threadedly connected with the sandblasting joint 2 . The sandblasting joint 2 is a hollow tubular structure. The guide rod 3 is ...

Embodiment 2

[0037] According to the drawings, this embodiment provides a cross-hole burr removal device, including a burr removal assembly 1, an abrasive cylinder 4, an abrasive cylinder pressurized intake pipe 5, an air compressor 6, and a compressed air discharge pipe 7. The burr The removal assembly 1 is threadedly connected with the compressed air discharge pipe 7, which is convenient for disassembly and has good sealing performance; Disassembly can also withstand higher air pressure, and the sealing performance is good; the air compressor 6 is flange-connected with the abrasive cylinder pressurized intake pipe 5 and the compressed air discharge pipe 7, which is easy to disassemble and can withstand high air pressure. Air pressure, and good sealing.

[0038] The abrasive cylinder 4 is set to a cylindrical structure, and the abrasive cylinder 4 belongs to a pressure vessel, and the cylindrical structure can allow the stress distribution of the abrasive cylinder to be uniform; the abras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com