System and method for preparing magnesium-zinc ferrite from acid pickling sludge and acid pickling waste liquor

A technology for pickling sludge and pickling waste liquid, which is applied in the field of hazardous waste recycling, can solve the problems of difficult treatment of pickling sludge and pickling waste liquid, and achieve the effect of realizing resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

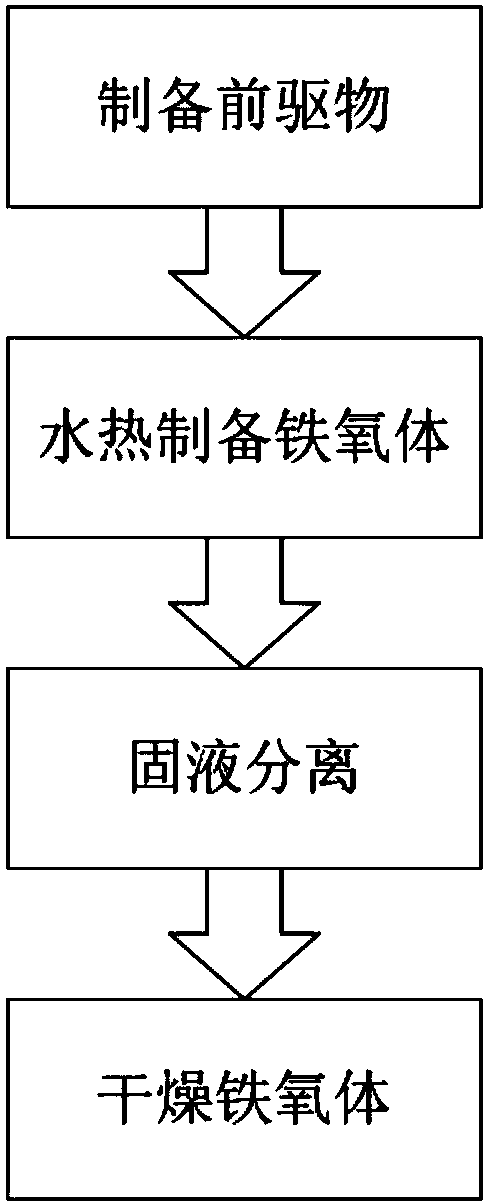

[0059] Such as figure 1 As shown, a system for preparing magnesium-zinc ferrite by using pickling sludge and pickling waste liquid includes a water storage tank 1, a water pump 2, a ferrite hydrothermal preparation device 3, a first feed pump 4, a second Two feed pump 5, acid storage tank 6, alkali storage tank 7, discharge pump 8, solid-liquid separation press filter device 9 and ferrite drying device 11, the water storage tank 1, the acid storage tank 6, The alkali storage tank 7 is connected to the ferrite hydrothermal preparation device 3 through the water pump 2, the first feed pump 4, and the second feed pump 5 respectively, and the ferrite hydrothermal The discharge port of the preparation device 3 is connected to the solid-liquid separation filter press device 9 through the discharge pump 8 , and the solid-liquid separation filter press device 9 is connected to the ferrite drying device 11 . The ferrite hydrothermal preparation device 3 has a stirring function, and th...

Embodiment 2

[0062] Such as figure 1 As shown, a system for preparing magnesium-zinc ferrite by using pickling sludge and pickling waste liquid, its structure is compared with that of Example 1, the difference is: the ferrite hydrothermal preparation device 3 includes A reaction kettle and an agitator, the agitator is located in the reaction kettle, the longitudinal section of the bottom of the reaction kettle is oval, and the bottom concave structure is conducive to the discharge of the ferrite mixed liquid, in order to achieve acid and alkali resistance For the purpose of high temperature and high pressure resistance, the agitator is made of polytetrafluoroethylene and has a U-shaped structure.

Embodiment 3

[0064] Such as figure 1 As shown, a system for preparing magnesium-zinc ferrite by using pickling sludge and pickling waste liquid, its structure is compared with that of Example 1, the difference is: the solid-liquid separation filter press device 9 is a plate frame Filter press, plate and frame filter press process can realize the effective separation of solids and liquids. At present, the water content can be reduced to 70% at most through this process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com