Method for preparing magnetic 5A molecular sieve from coal gangue and application of magnetic 5A molecular sieve

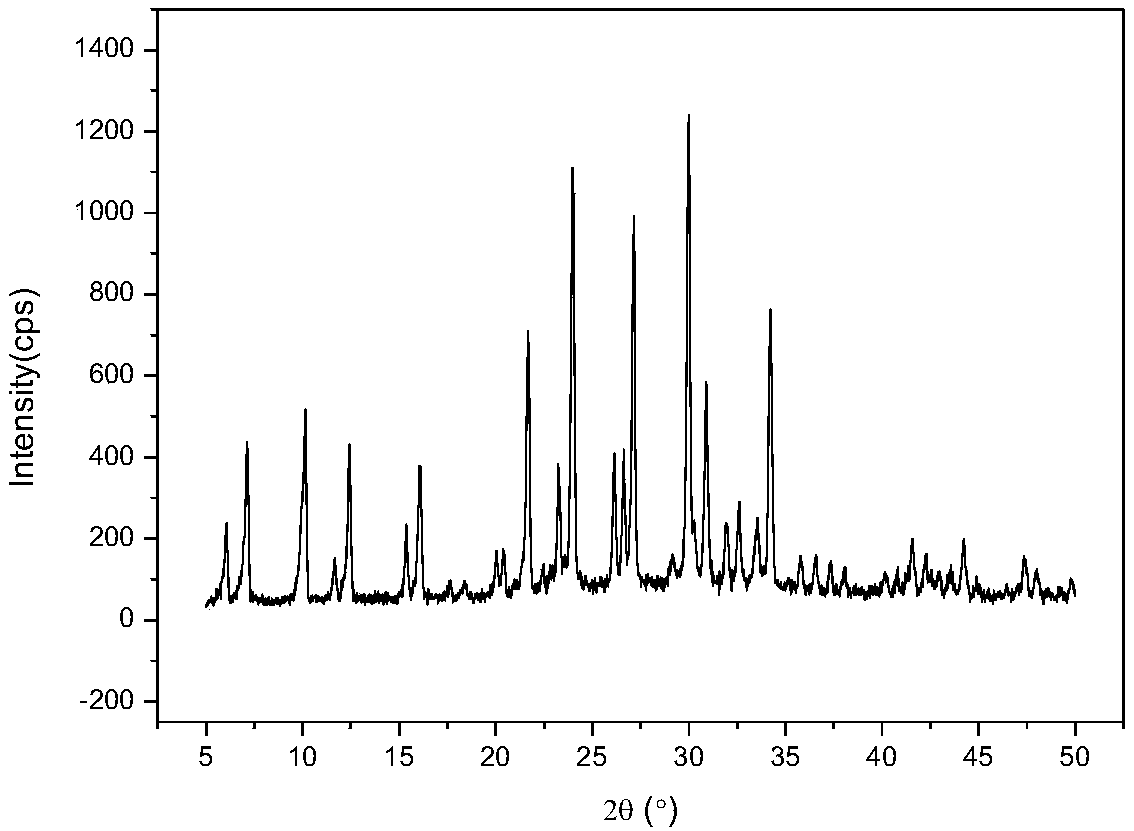

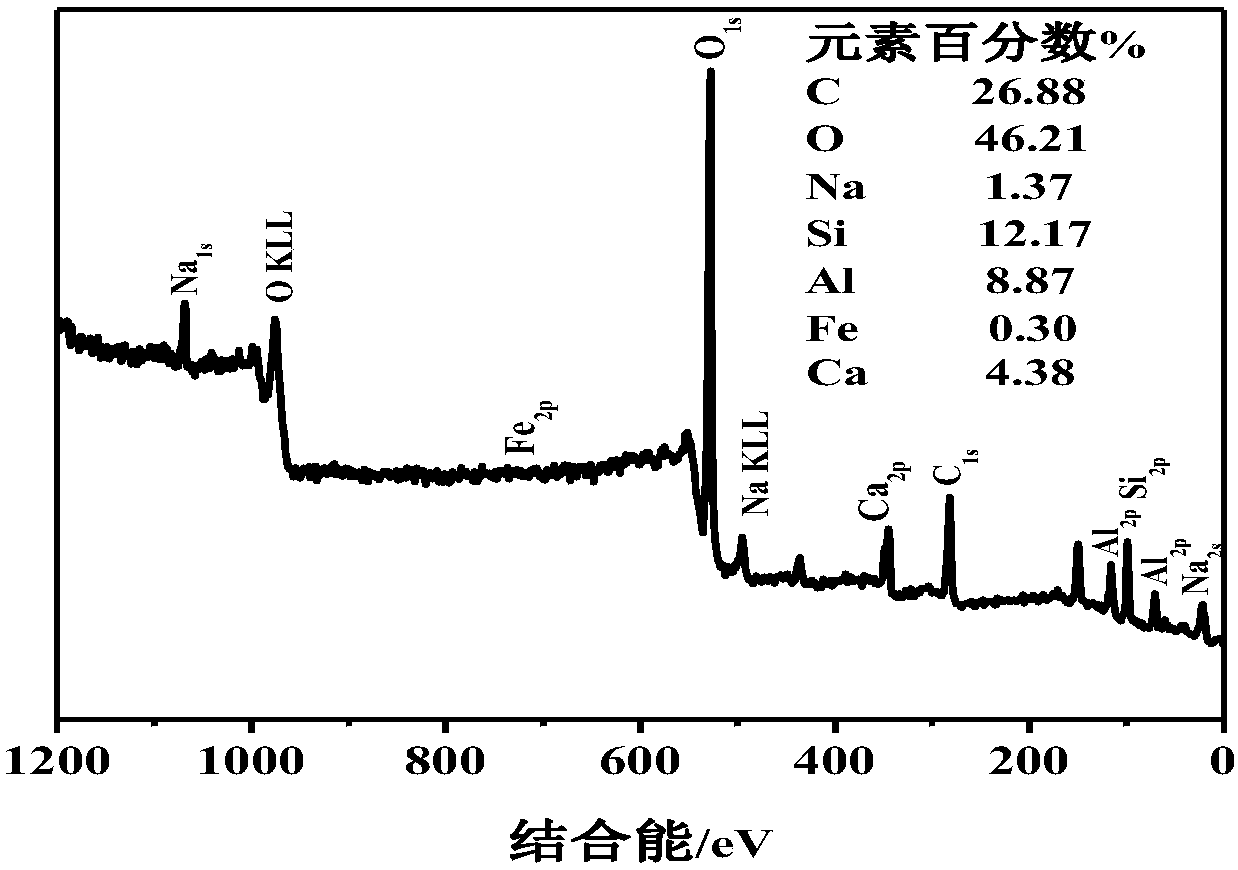

A molecular sieve and coal gangue technology, applied in the field of preparation of magnetic 5A molecular sieve, can solve problems such as high cost, and achieve the effects of high crystallinity, regular crystal morphology and uniform crystal distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment utilizes coal gangue to prepare magnetic 5A molecular sieves, including the following steps:

[0038] Step 1: Grind coal gangue to 325 mesh and place it in an ash dish, then add sodium carbonate to the ash dish, roast for 3 hours at a temperature of 850° C. and then grind to obtain a pretreated sample; the coal gangue and carbonic acid The mass ratio of sodium is 2:1;

[0039] Step 2, oxidizing the pretreated coal gangue powder at 350°C for 2h, adding hydrochloric acid with a mass concentration of 15%, soaking at 95°C for 2h, and filtering to obtain filtered solids and filtrate;

[0040] Step 3. Weigh 3.36g of NaOH and 150ml of deionized water and dissolve them in a 500ml Erlenmeyer flask; add cobalt acetate to the filtrate, and add 0.1g of cobalt acetate to each gram of gangue. After dissolving, pour the filtrate into boiling In the Erlenmeyer flask, reflux for 1h, wash and filter to pH=7, and dry to obtain magnetic ferric cobaltate;

[0041] Step 4. ...

Embodiment 2

[0048] This embodiment utilizes coal gangue to prepare magnetic 5A molecular sieves, including the following steps:

[0049] Step 1: Grind coal gangue to 325 mesh and place it in an ash dish, then add sodium carbonate to the ash dish, roast for 3 hours at a temperature of 880° C. and then grind to obtain a pretreated sample; the coal gangue and carbonic acid The mass ratio of sodium is 2.5:1;

[0050] Step 2, oxidize the pretreated coal gangue powder at 350° C. for 2 hours, add hydrochloric acid with a mass concentration of 15%, soak at 95° C. for 3 hours, and filter to obtain filtered solids and filtrate;

[0051] Step 3. Weigh 3.36g of NaOH and 150ml of deionized water and dissolve them in a 500ml Erlenmeyer flask; add cobalt acetate to the filtrate, and add 0.08g of cobalt acetate to each gram of coal gangue. After dissolving, pour the filtrate into boiling In the Erlenmeyer flask, reflux for 1h, wash and filter to pH=7, and dry to obtain magnetic ferric cobaltate;

[005...

Embodiment 3

[0055] This embodiment utilizes coal gangue to prepare magnetic 5A molecular sieves, including the following steps:

[0056] Step 1: Grind coal gangue to 325 mesh and place it in an ash dish, then add sodium carbonate to the ash dish, roast for 2 hours at a temperature of 900° C. and then grind to obtain a pretreated sample; the coal gangue and carbonic acid The mass ratio of sodium is 3:1;

[0057] Step 2, oxidizing the pretreated coal gangue powder at 400°C for 2h, adding hydrochloric acid with a mass concentration of 15%, soaking at 85°C for 3h, and filtering to obtain filtered solids and filtrate;

[0058] Step 3. Weigh 3.36g of NaOH and 150ml of deionized water and dissolve them in a 500ml Erlenmeyer flask; add cobalt acetate to the filtrate, and add 0.09g of cobalt acetate to each gram of gangue. After dissolving, pour the filtrate into boiling In the Erlenmeyer flask, reflux for 1h, wash and filter to pH=7, and dry to obtain magnetic ferric cobaltate;

[0059] Step 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com