Three-phase tissue engineering scaffold

A tissue engineering scaffold, a three-phase technology, applied in tissue regeneration, prosthesis, medical science, etc., can solve the problems of lack of gradient structure regeneration, easy re-fracture of bone and tendon structure, and inability to disperse stress and avulsion of bone and tendon junctions. , to accelerate the decellularization process, reduce the decellularization time, and promote regeneration and healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

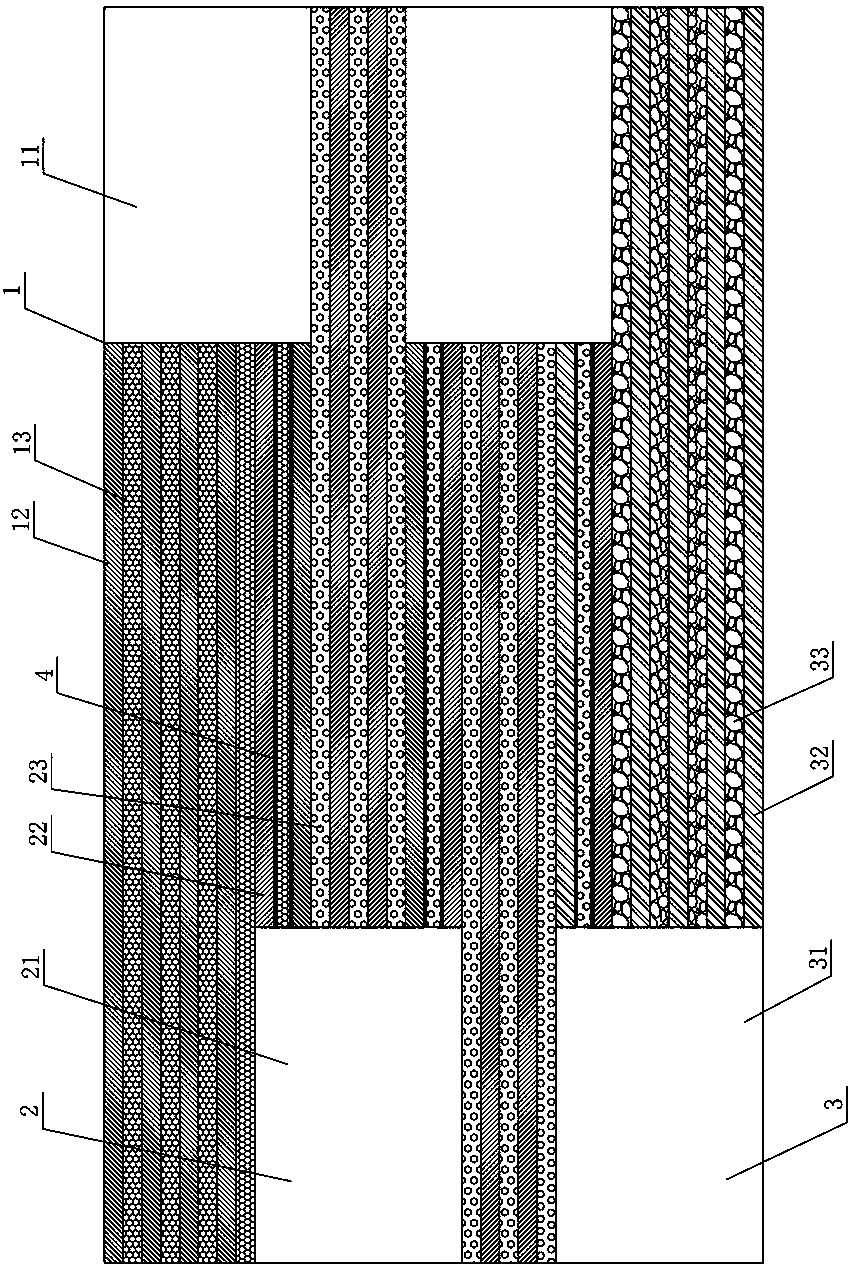

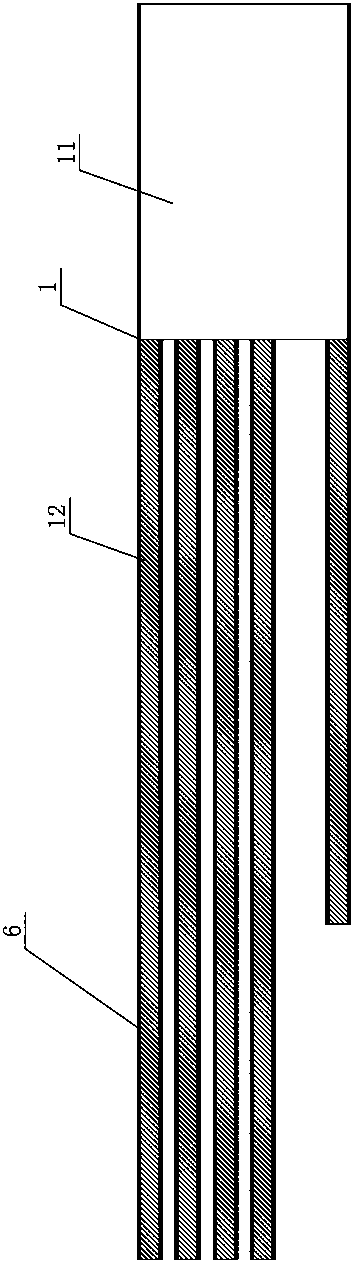

[0022] like Figure 1 to Figure 3 As shown, an embodiment of the three-phase tissue engineering scaffold of the present invention includes a bone scaffold 1, a cartilage scaffold 2 and a tendon scaffold 3 stacked and integrated sequentially from top to bottom, and one end of the bone scaffold 1 is set as a bone fixation cladding part 11. The other end of the bone bracket 1 is cut transversely and provided with a plurality of bone leaf sheets 12 extending to the bone fixation wrapping part 11, and a bone differentiation cell sheet 13 is arranged between each bone leaf sheet 12; one end of the cartilage bracket 2 Set as the cartilage-fixed wrapping portion 21, the other end of the cartilage support 2 is cut transversely and provided with a plurality of cartilage-like leaf sheets 22 extending to the cartilage-fixed wrapping portion 21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com