Multi-stage exhaust gas turbocharger

A technology of exhaust gas turbine and supercharger, which is applied to gas turbine devices, non-variable pumps, non-volume pumps, etc., to achieve the effects of increased efficiency, good cooling, and less structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

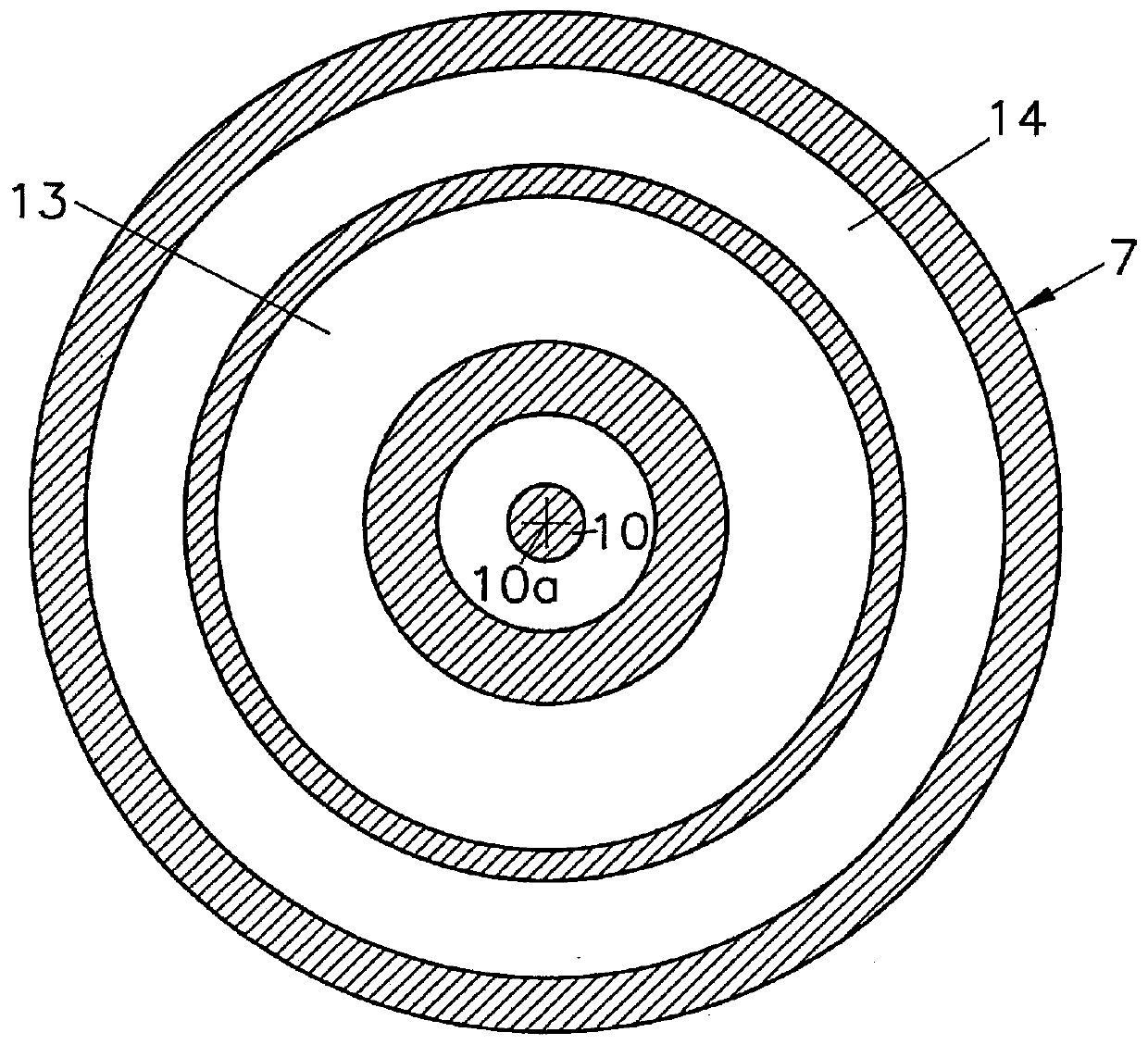

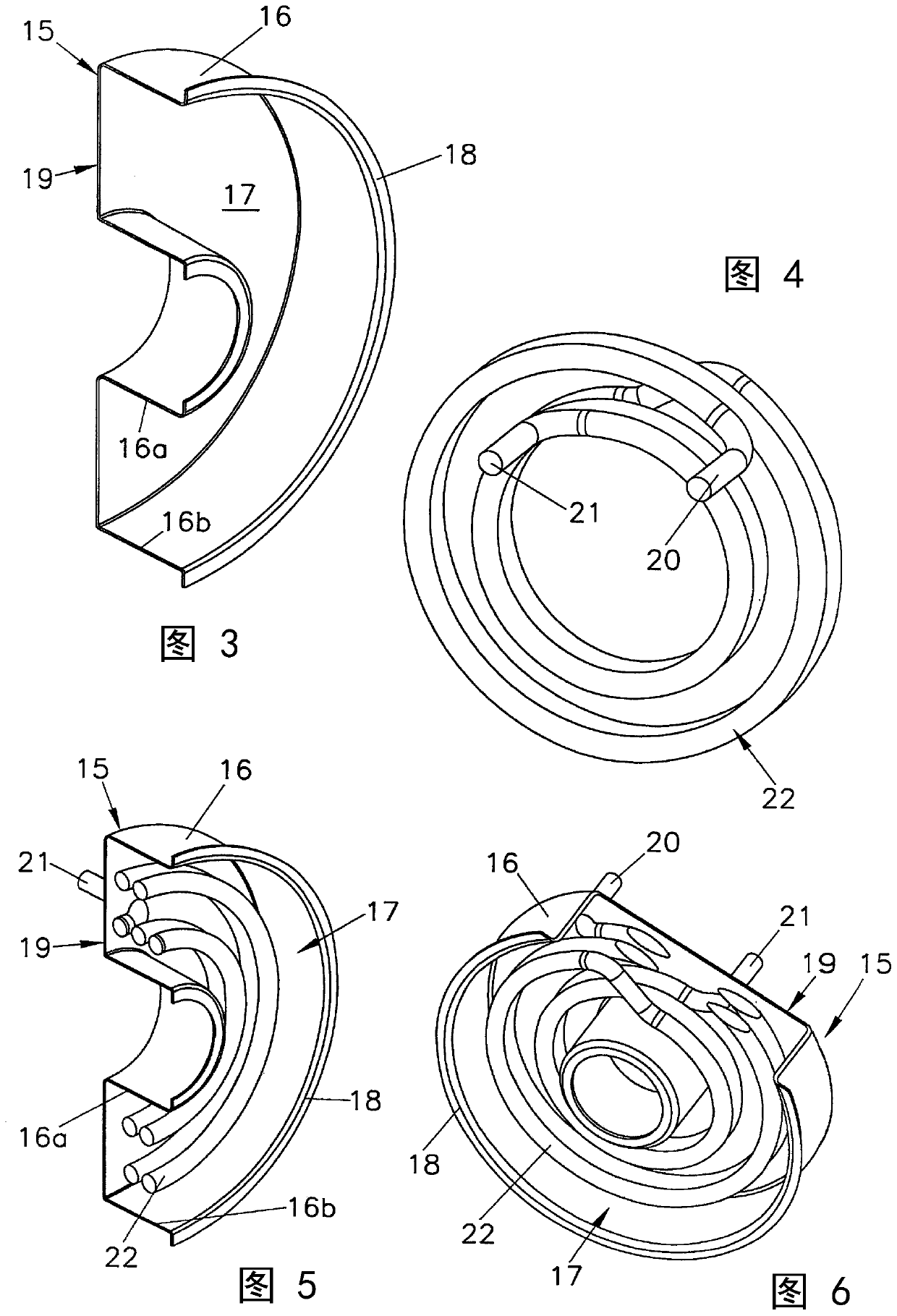

[0057] figure 1 A compressor 1 a of an exhaust gas turbocharger 2 is shown, which has a first compressor stage 3 and a second compressor stage 4 . A compressor rotor 9 configured with rotor wheels 5 , 6 on both sides and arranged in the compressor housing part 7 of the exhaust gas turbocharger housing 8 is mounted rotatably in the exhaust gas turbocharger housing 8 about an axis of rotation 10 a The shaft 10 of the exhaust gas turbocharger 2 is non-rotatably connected to a turbine rotor (not further shown) of the exhaust gas turbine of the exhaust gas turbocharger 2 . The compressor housing part 7 has an axial compressor inlet 11 connected to a not further shown fresh air line for taking in fresh air and a connection to the charge air line of the internal combustion engine indicated by reference numeral 12 for Compressor outlet for charge air. The flow of air is indicated by arrow S.

[0058] The compressor stage outlet 13 from the first compressor stage 3 is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com