Upper furnace lid of waste aluminum melting furnace and having temperature measuring function

A technology of aluminum smelting furnace and temperature measurement function, which is applied in the direction of furnace, furnace charge, furnace components, etc., which can solve the problems of inconvenient operation for operators and failure to see the furnace on the upper furnace body, and achieve the effect of convenient operation for employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

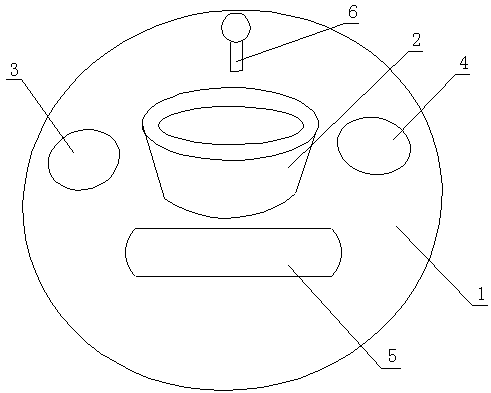

[0011] see figure 1 , the upper furnace cover of a waste aluminum smelting furnace with a temperature measuring function related to the present invention includes a furnace cover body 1, an isolation valve 2 is provided at the middle opening of the furnace cover body 1, and the isolation valve 2 is used to install The flange is connected to the auxiliary furnace. The furnace cover body 1 has a water inlet 3 and a water outlet 4 on both sides of the isolation valve 2, which are used to connect with the water inlet and outlet joints. The furnace cover body 1 is also provided with an observation window. 5 is used to observe the situation in the upper furnace body, the observation window 5 is a through hole opened on the top of the furnace cover body 1, and tempered glass is installed in the through hole, and a handle 6 is also fixed on the furnace cover body 1 , for conveniently opening the upper furnace cover, the top of the furnace cover body 1 is provided with a plurality of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com