Preheating relay fixing tool

A technology for fixing tooling and relays, applied to workpiece clamping devices, workbenches, manufacturing tools, etc., can solve the problems of unfavorable operator safety, control, and distracting operator attention, so as to facilitate the operation of employees and reduce potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments, but this does not constitute any limitation to the present invention.

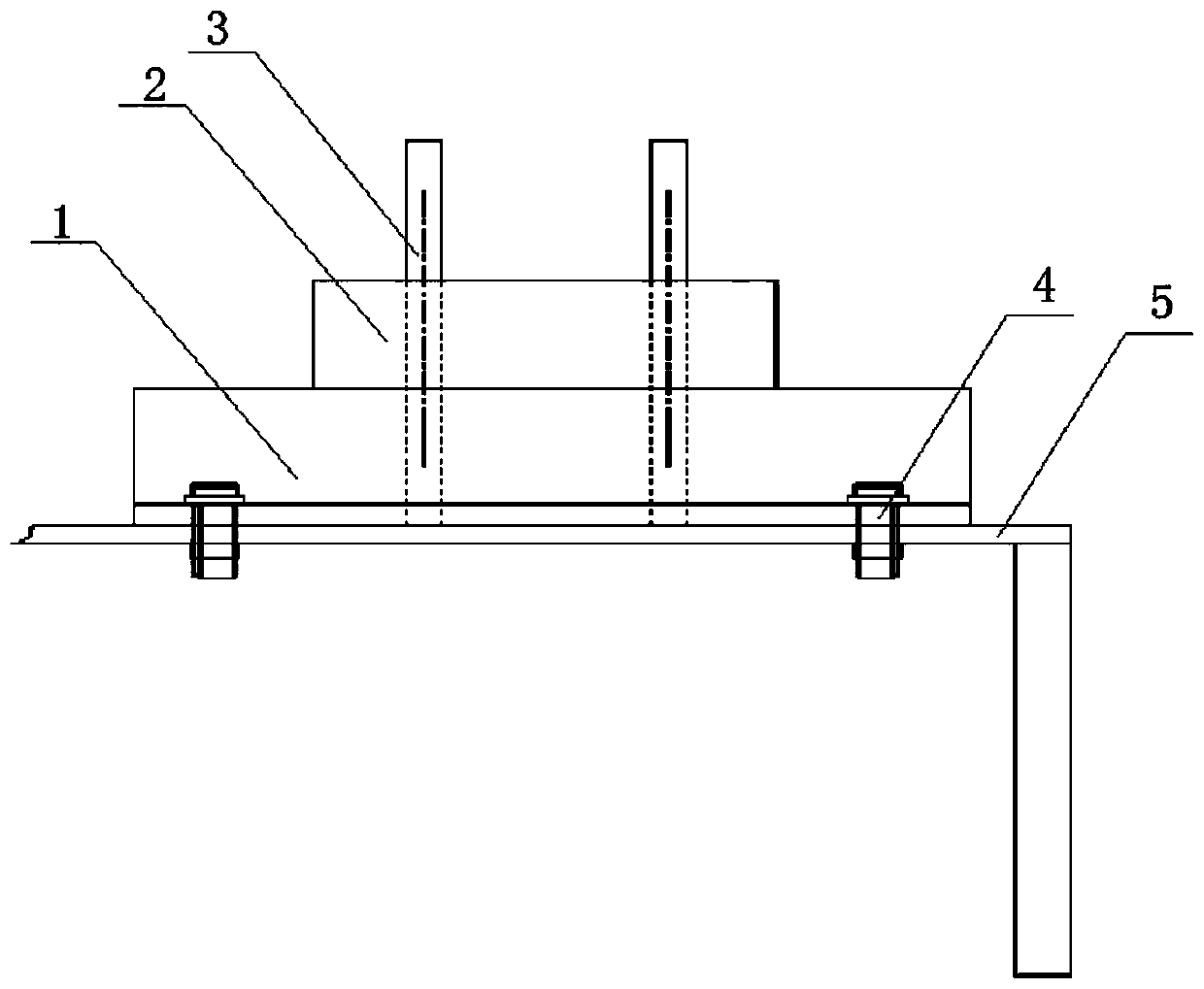

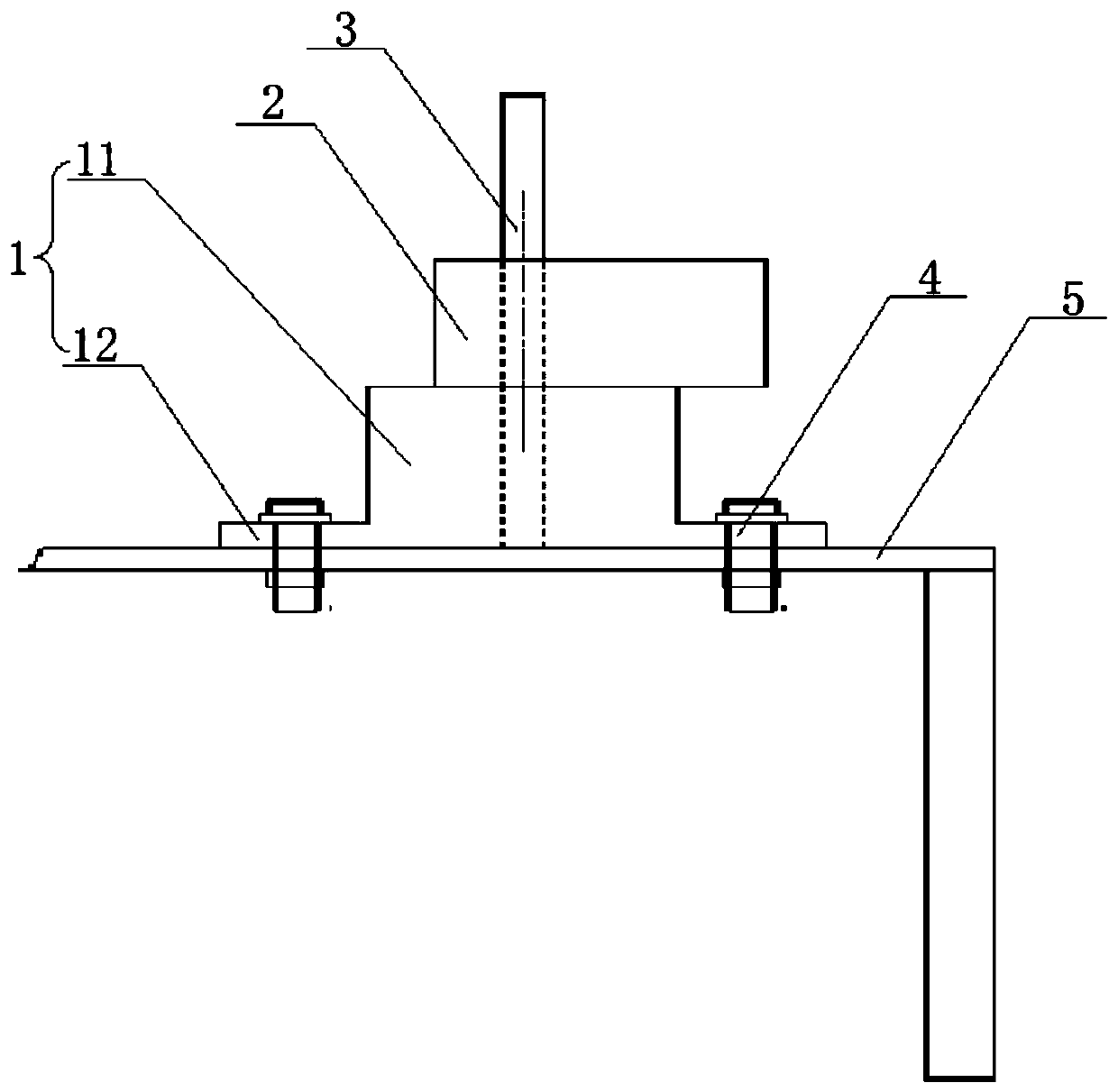

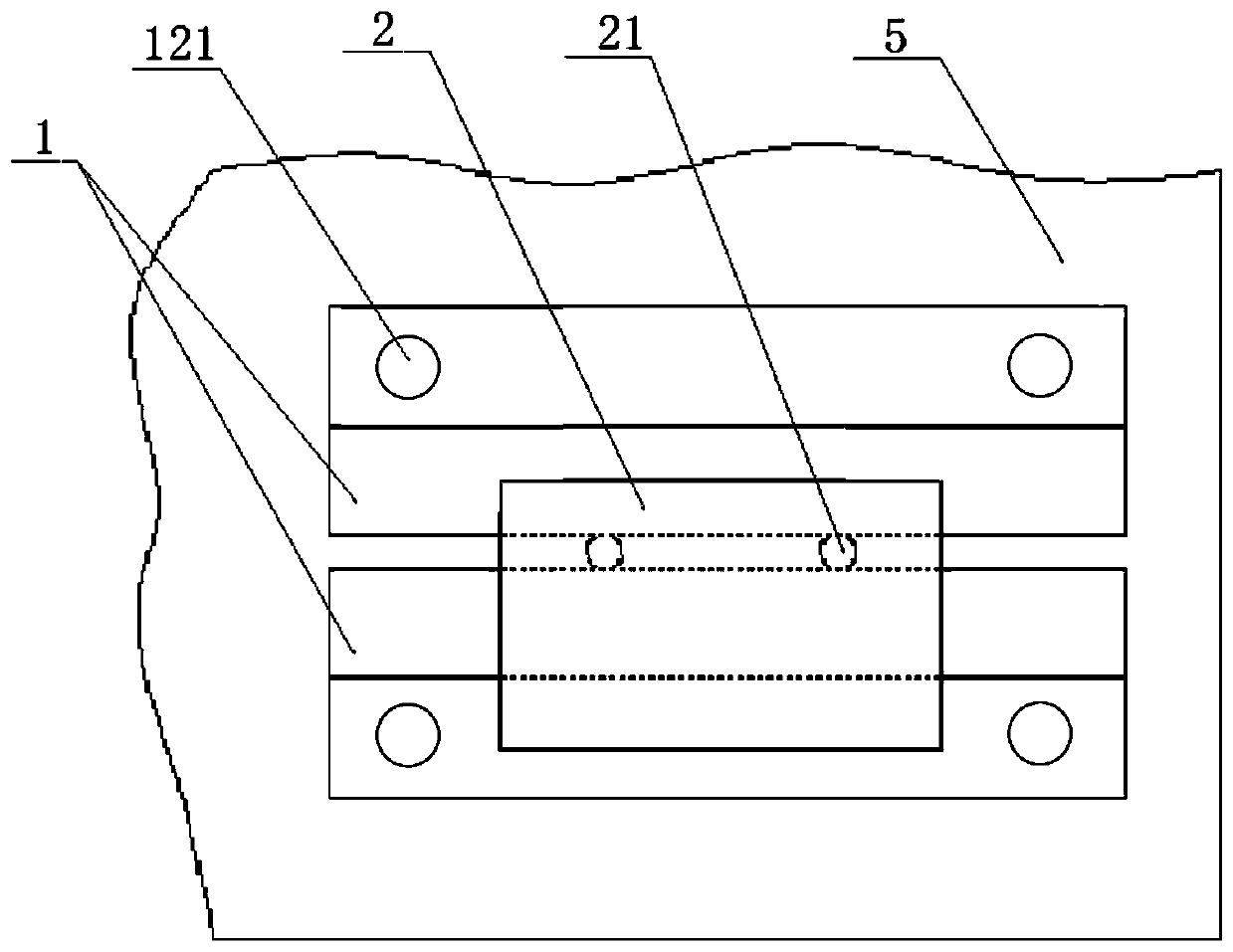

[0019] refer to Figure 1 to Figure 3 As shown, a preheating relay fixing tool of the present invention includes two support frames 1 arranged at intervals on the workbench 5, each support frame 1 includes a support platform 11, and a positioning bracket is arranged on the top surface of the support platform 11. Block 2, the positioning block 2 is provided with several through holes 21 corresponding to the positions of the slots on the preheating relay bracket, the through holes 21 are pierced with matching positioning rods 3, and the bottom of the positioning rods 3 is placed on two sides. In the installation gap of a supporting platform 11.

[0020] The distance between the two support platforms 11 is greater than the diameter of the positioning rod 3. Preferably, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com