Hydrate inhibitor and application thereof

A hydrate inhibitor and hydrate technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of low inhibitory activity, poor biodegradability, high synthesis cost, etc., and achieve no cumulative effect and no harmfulness Small and versatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

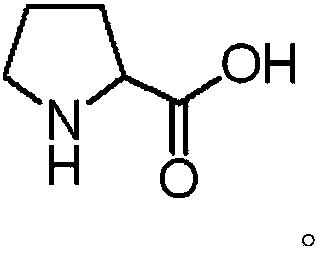

[0028] The hydrate inhibitor of this embodiment is proline, and the method for using it to inhibit hydrate comprises the following steps:

[0029] 1. Solution preparation

[0030] The proline was completely dissolved in deionized water to prepare a proline solution with a molar concentration of 3 mol / L (mass concentration was 34.5%).

[0031] 2. Hydrate inhibition

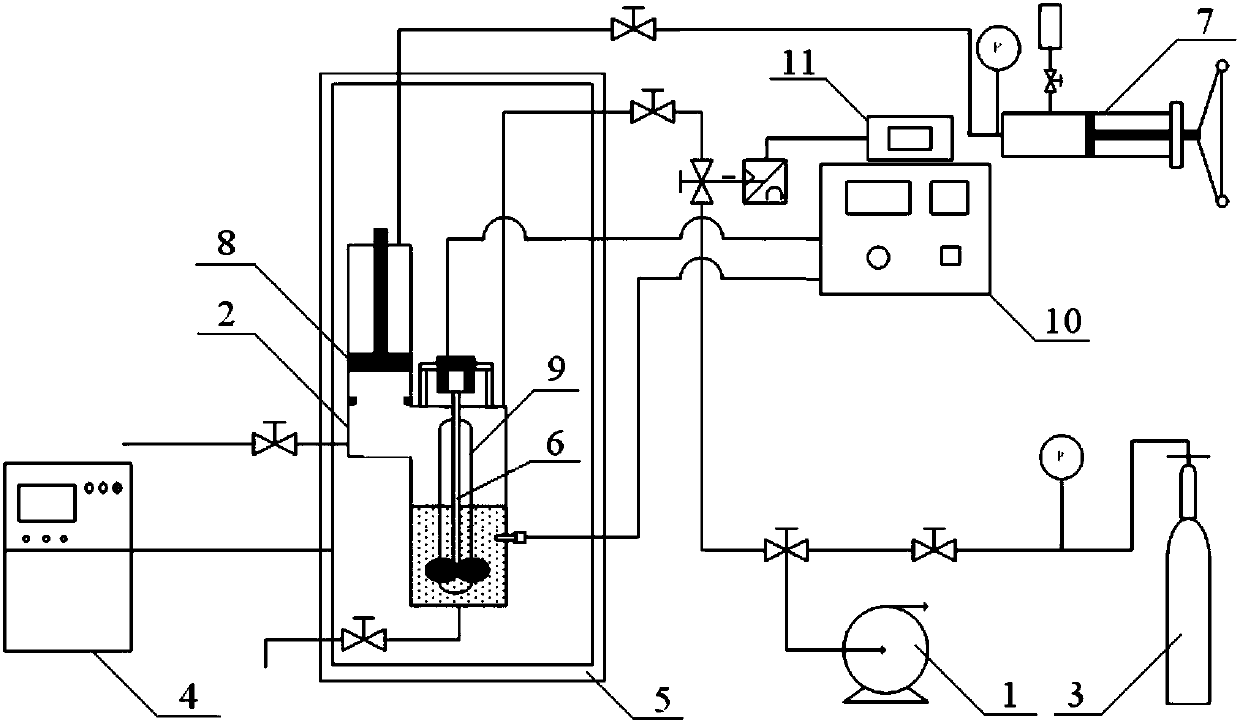

[0032] use figure 1 The reaction system shown was subjected to the hydrate inhibition test, wherein: the system used in this example was a gas-water system, the hydrate inhibitor was a 3mol / L proline solution, and the gas was CH 4 , the constant temperature and pressure search method is used to obtain the equilibrium condition of the hydrate, and the experimental temperature is set to 9.99°C. The specific steps are as follows:

[0033] 1) Use the vacuum pump 1 to evacuate the reactor 2, and then use negative pressure to inhale deionized water to clean the reactor 2 until it is cleaned;

[0034] 2) Rinse the rea...

Embodiment 2

[0045] The system used in this example is a gas-water system, the hydrate inhibitor is a 3mol / L proline solution, and the gas is CH 4 , the constant temperature and pressure search method was used to obtain the equilibrium condition of hydrate, the experimental temperature was set at 6.11°C, and the hydrate inhibition test was carried out using the same steps as in Example 1.

[0046] After testing, in this embodiment, after trace hydrates exist stably and the pressure is stable for 4 hours, the obtained equilibrium pressure value is 9.0Mpa; at the same time, the blank control test (i.e. replace the above-mentioned proline with deionized water without proline Acid solution) obtained equilibrium pressure value is 4.69Mpa.

[0047] This shows that: at about 6°C, the hydrate inhibitor of this example can increase the equilibrium pressure value by 4.31Mpa when the concentration is 3mol / L, indicating that the hydrate inhibitor can significantly improve the formation conditions of h...

Embodiment 3

[0049] The system used in this example is a gas-water system, the hydrate inhibitor is a proline solution with a mass concentration of 21.9 wt%, and the gas is CH 4 , the constant temperature and pressure search method was used to obtain the equilibrium condition of hydrate, the experimental temperature was set at 10.0°C, and the hydrate inhibition test was carried out using the same steps as in Example 1.

[0050] After testing, in this embodiment, after trace hydrates exist stably and the pressure is stable for 4 hours, the obtained equilibrium pressure value is 9.36Mpa; at the same time, the blank control test (i.e. replace the above-mentioned proline with deionized water without proline Acid solution) obtained equilibrium pressure value is 7.25Mpa.

[0051] This shows that: at about 10°C, the hydrate inhibitor of this example can increase the equilibrium pressure value by 2.11Mpa when the mass concentration is 21.9wt%, indicating that the hydrate inhibitor can significantl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com