A composite refrigerant suitable for the temperature range of -45°C to 90°C

A refrigerant and temperature zone technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as pressure rise and affect the safety of cooling systems, achieve large latent heat of gasification, be conducive to miniaturization, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

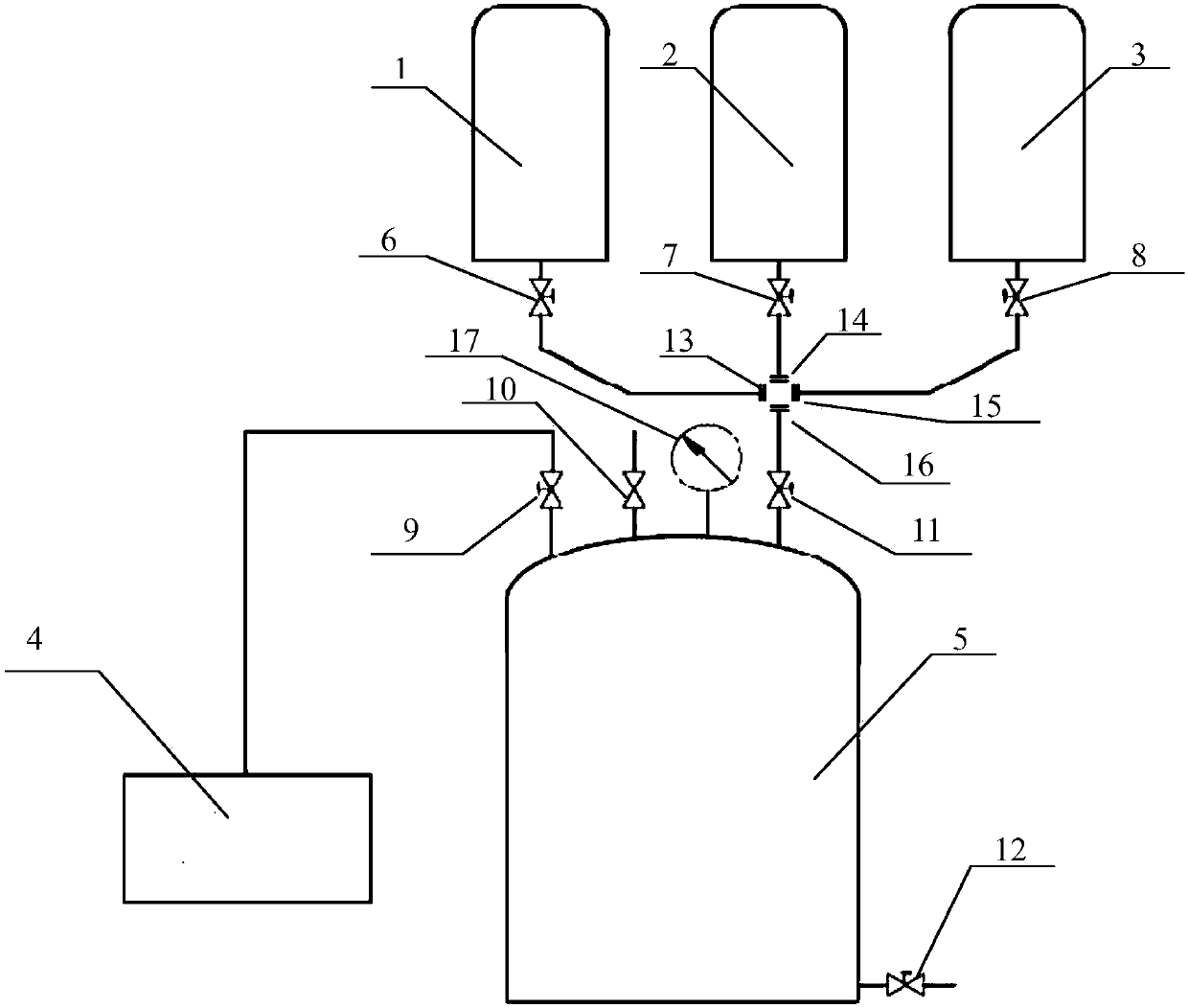

[0045] (1) First open the first manual shut-off valve 7, the third manual shut-off valve 11, and the fourth manual shut-off valve 12, clean the steel container 5 and the mixing container 2 twice with pure water, and then clean it with absolute alcohol 2 times. After cleaning, empty the alcohol, close the first manual shut-off valve 7, the third manual shut-off valve 11 and the fourth manual shut-off valve 12.

[0046] (2) Open the first manual shut-off valve 7, add dichloromethane and fluorodichloroethane into the mixing container 2 in a ratio of 4:1 by weight, close the first manual shut-off valve 7, shake fully for 1 min, and obtain a mixed liquid.

[0047] (3) Open the second manual shut-off valve 9, use the vacuum unit 4 to vacuum pump the steel container 5, and remove the gas in the steel container 5. When the vacuum degree is stable below 100Pa, close the second hand after the vacuum is finished. Move shut-off valve 9, vacuum unit 4 stops.

[0048](4) Connect the seco...

Embodiment 2

[0053] (1) First open the first manual shut-off valve 7, the third manual shut-off valve 11, and the fourth manual shut-off valve 12, clean the steel container 5 and the mixing container 2 twice with pure water, and then clean it with absolute alcohol 2 times. After cleaning, empty the alcohol, close the first manual shut-off valve 7, the third manual shut-off valve 11 and the fourth manual shut-off valve 12.

[0054] (2) Open the first manual shut-off valve 7, add dichloromethane and fluorodichloroethane into the mixing container 2 in a ratio of 3:1 by weight, close the first manual shut-off valve 7, shake fully for 1 min, and obtain a mixed liquid.

[0055] (3) Open the second manual shut-off valve 9, use the vacuum unit 4 to vacuum pump the steel container 5, and remove the gas in the steel container 5. When the vacuum degree is stable below 100Pa, close the second hand after the vacuum is finished. Move shut-off valve 9, vacuum unit 4 stops.

[0056] (4) Connect the sec...

Embodiment 3

[0061] (1) First open the first manual shut-off valve 7, the third manual shut-off valve 11, and the fourth manual shut-off valve 12, clean the steel container 5 and the mixing container 2 twice with pure water, and then clean it with absolute alcohol 2 times. After cleaning, empty the alcohol, close the first manual shut-off valve 7, the third manual shut-off valve 11 and the fourth manual shut-off valve 12.

[0062] (2) Open the first manual shut-off valve 7, add dichloromethane and fluorodichloroethane into the mixing container 2 in a ratio of 5:1 by weight, close the first manual shut-off valve 7, shake fully for 1 min, and obtain a mixed liquid.

[0063] (3) Open the second manual shut-off valve 9, use the vacuum unit 4 to vacuum pump the steel container 5, and remove the gas in the steel container 5. When the vacuum degree is stable below 100Pa, close the second hand after the vacuum is finished. Move shut-off valve 9, vacuum unit 4 stops.

[0064] (4) Connect the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com