Limiting plate structure, upper reactor inner component and suspension basket component

A technology of limiting plates and internal components, applied in the direction of reactor fuel elements, reactors, nuclear power generation, etc., can solve the problem of high structural strength requirements of fuel components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

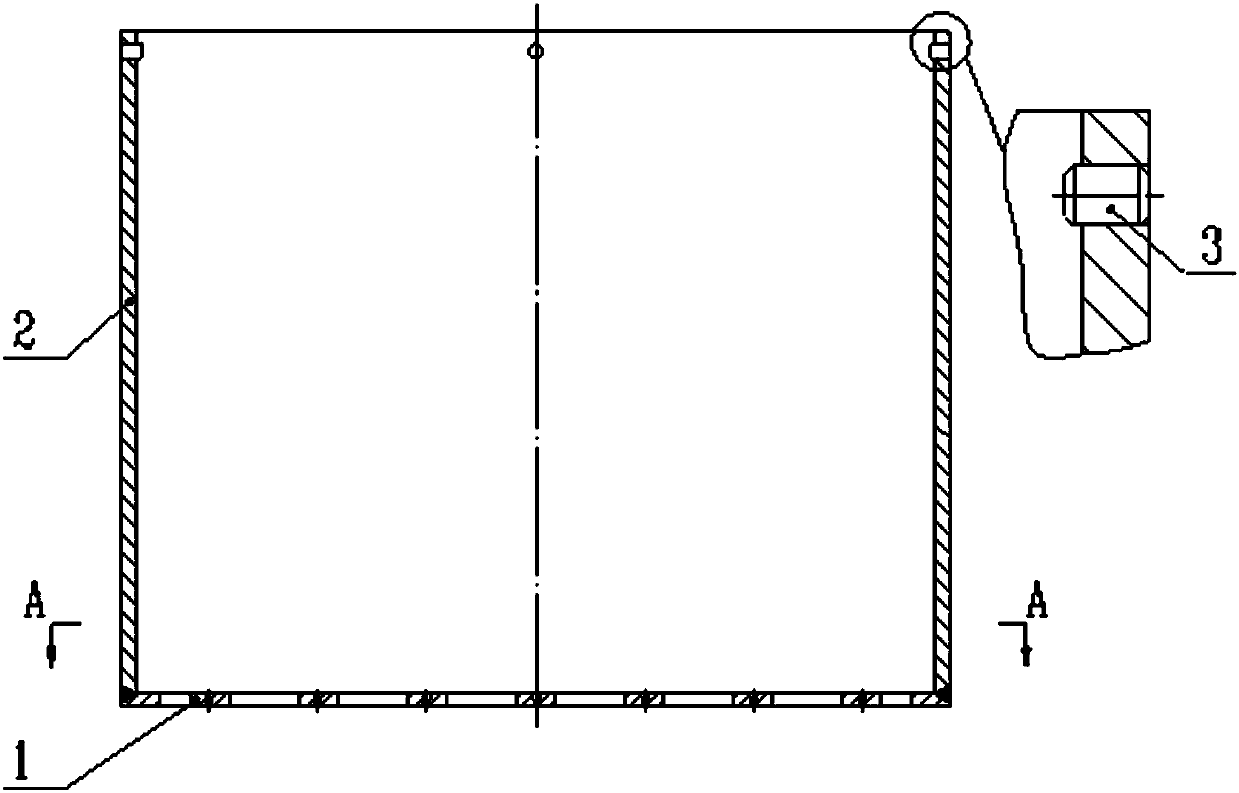

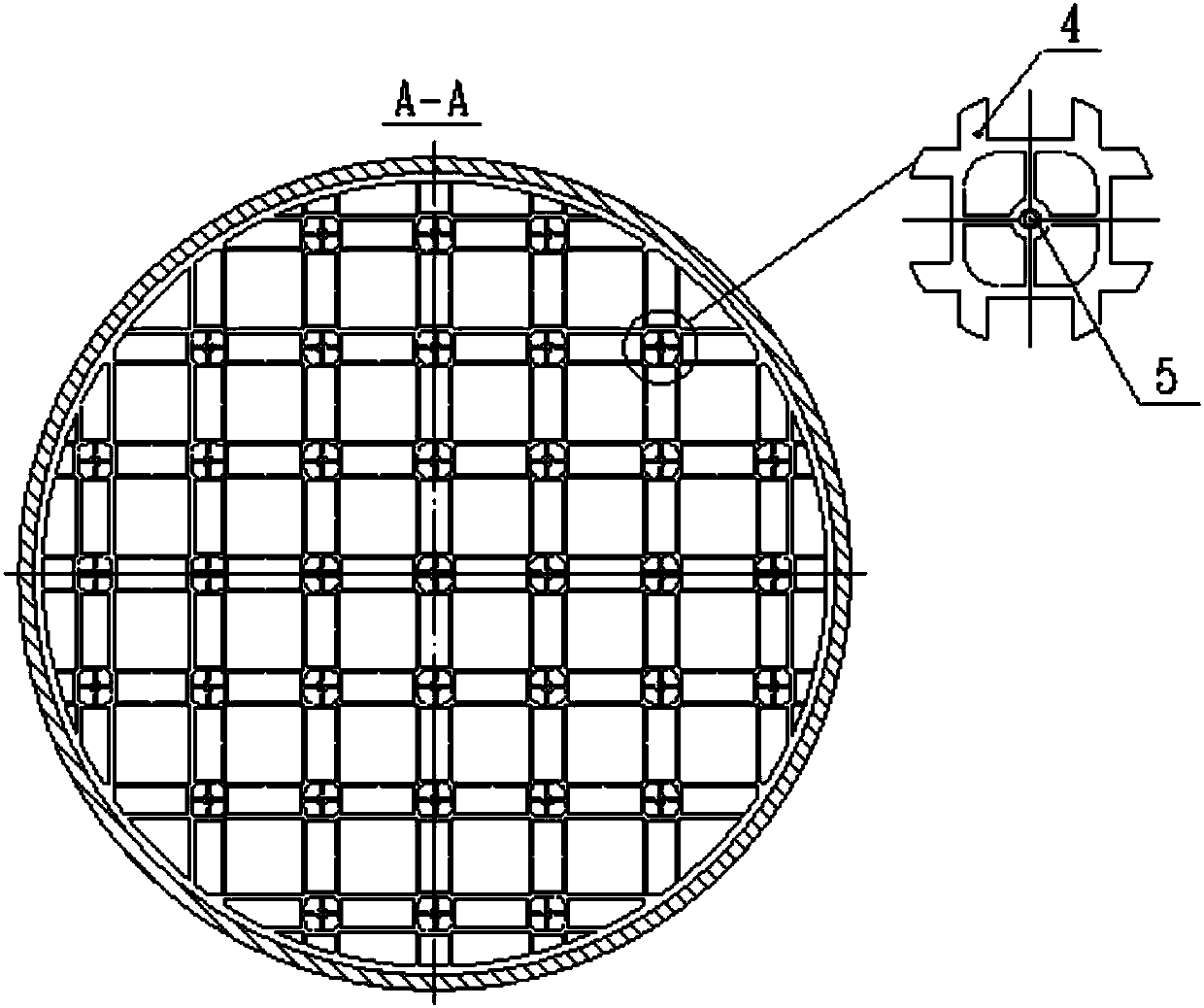

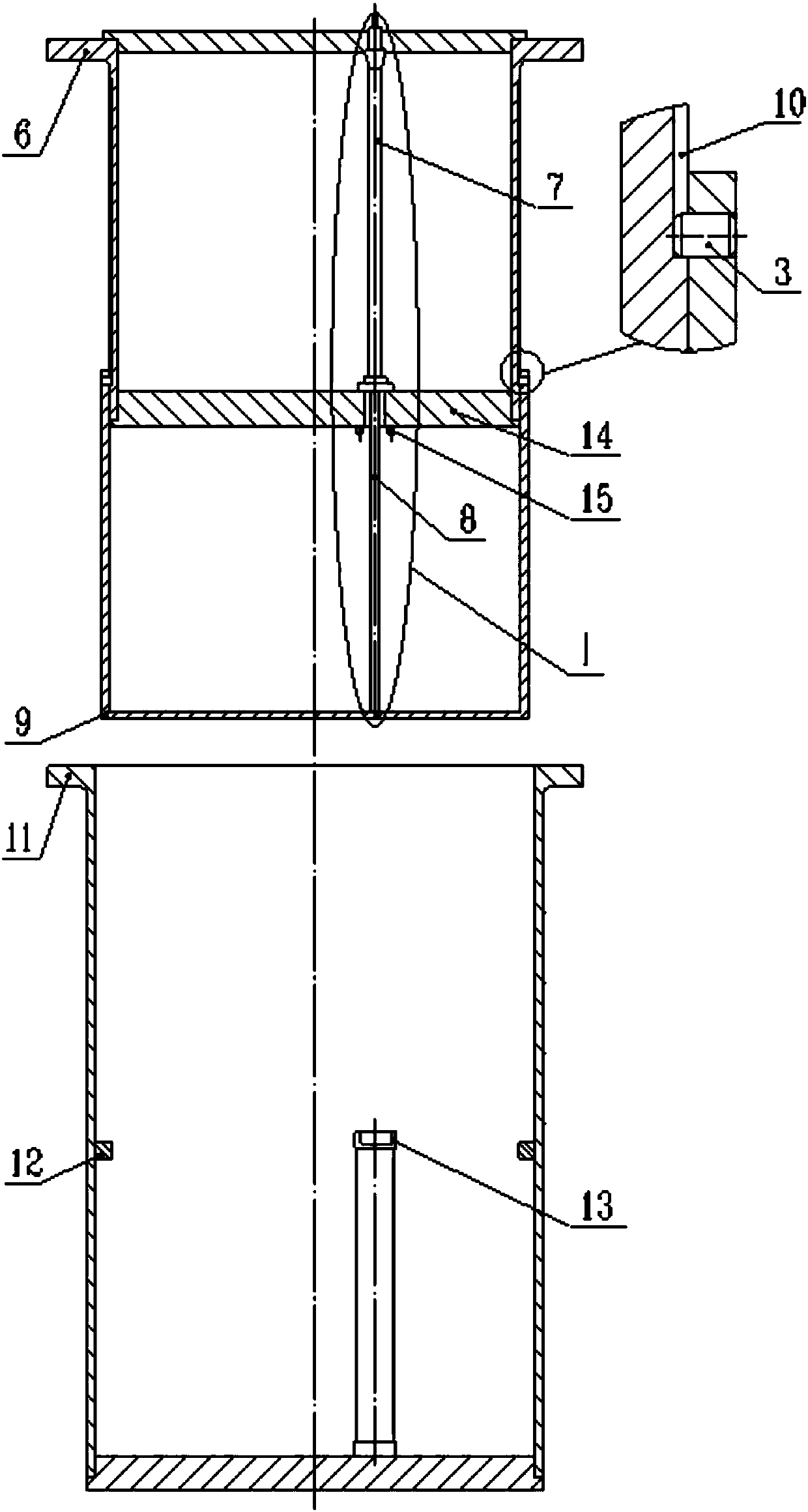

[0040] Such as Figure 1 to Figure 7 As shown, this embodiment provides a limit plate structure, upper internal components and basket assembly, such as figure 1 As shown, the limit plate structure 9 is composed of a lower end plate 1 and a sliding cylinder 2 welded, as figure 2 As shown, the lower end plate 1 has the characteristics of a grid frame 4, and each grid frame 4 has a through hole 5 in the center.

[0041] Such as image 3 As shown, several positioning pins 3 of the limiting plate structure 9 pass through the sliding cylinder 2 and are inserted into the axial slots 10 outside the cylinder of the upper internals 6. When the nuclear reactor is first installed, the upper internals 6 Before hoisting into the hanging basket assembly 11, the positioning pin 3 is located at the bottom of the axial slot 10 outside the cylinder. The end of the bushing 8 is supported on the lower end plate 1. When the upper internal component 6 is hoisted into the hanging basket assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com