Airtightness detection apparatus for manufacture of power supply module

An air-tightness detection and power module technology, which is applied in the direction of using liquid/vacuum degree for liquid-tightness measurement, by measuring the acceleration and deceleration rate of fluid, etc. Large workload and other problems, to achieve the effects of high detection efficiency and accuracy, internal safety of the battery, and fast ventilation and deflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

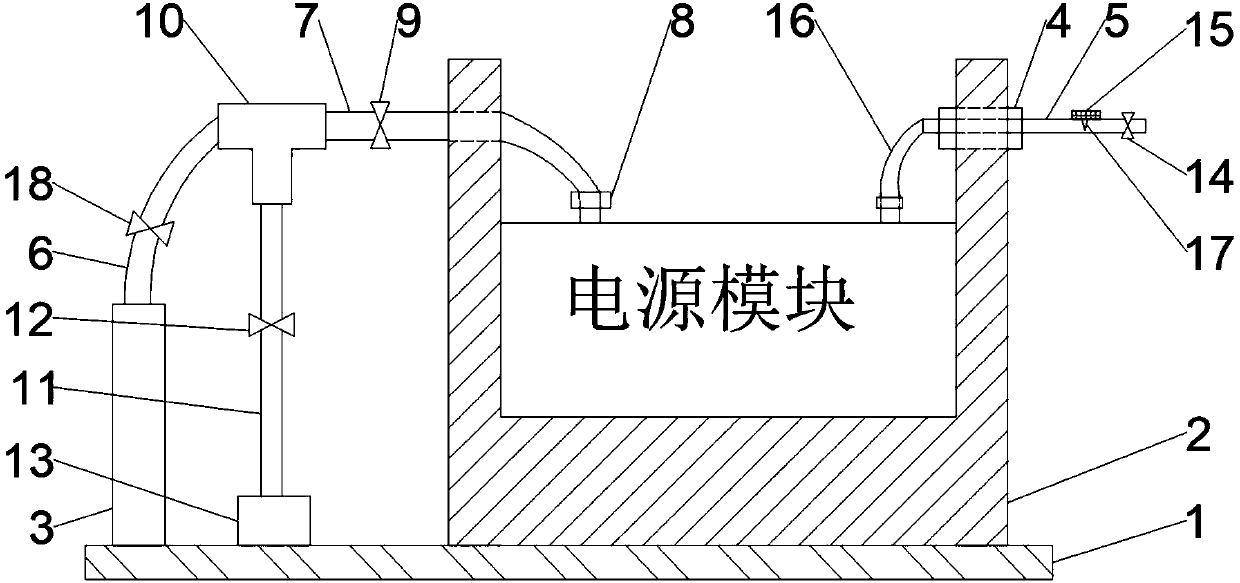

[0025] Such as figure 1 As shown, the present invention provides an air tightness detection device for power module manufacturing, including a base plate 1, a detection seat 2 is fixedly installed on the base plate 1, the inner shape of the detection seat 2 is a rectangle, and the air pipe 6 An air valve 18 is installed on it, which is more convenient for placing a relatively large power module. The function of the detection seat 2 is to fix the power module for easy detection. The left side of the detection seat 2 is provided with a helium pump 3, and the right side of the detection seat 2 is equipped with an air outlet pipe 5 through the air pipe fixing seat 4. The air pipe fixing seat 4 can not only fix the air outlet pipe 5, but also prevent the air outlet pipe 5 from being affected. The friction of the side plate of the detection seat 2 protects the air outlet pipe 5. The air outlet pipe 5 is a hard air pipe, and the axis of the air outlet pipe 5 is parallel to the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com