Anti-corrosion waste aluminum smelting furnace

An aluminum smelting furnace, anti-corrosion technology, applied in furnaces, crucible furnaces, furnace maintenance, etc., can solve the problems of inconvenient disassembly and assembly of single crystal furnace body, long time for disassembly or screw tightening, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

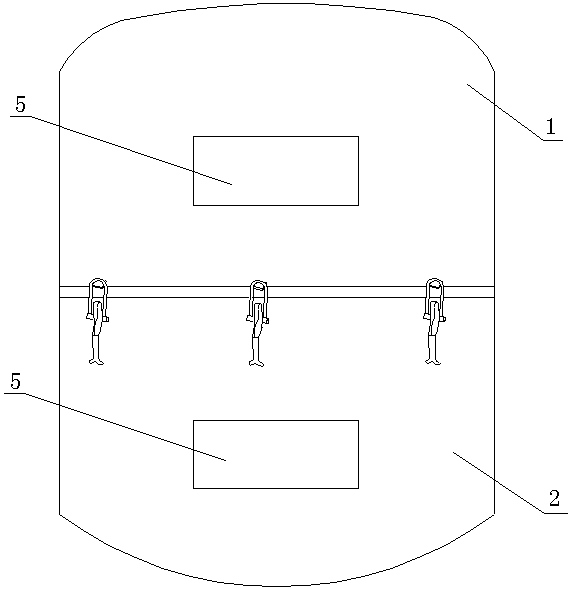

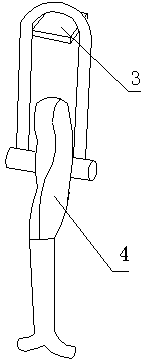

[0012] See figure 1 with figure 2 , The present invention relates to an anti-corrosion scrap aluminum smelting furnace, which includes an upper furnace body 1 and a lower furnace body 2. A plurality of bumps 3 are provided on the side wall of the lower part of the upper furnace body 1 and the lower furnace body 2 A number of box buckles 4 are provided on the upper side wall, and the number of the box buckles 4 is the same as that of the bumps 3, and each box buckle 4 is arranged below the bump 3, and the box buckles 4 are opposite to the bumps 3. Cooperate, when the upper furnace body 1 and the lower furnace body 2 need to be disassembled, it can be easily completed by loosening or buckling the box button 4, which improves the disassembly and assembly efficiency of the upper furnace body 1 and the lower furnace body 2. Both the upper furnace body 1 and the lower furnace body 2 are provided with an observation port 5. The observation port 5 can easily see the inside of the smel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com