Heat cycle type energy-saving drying equipment

A drying equipment and thermal cycle technology, applied in lighting and heating equipment, drying solid materials, drying gas layout, etc., can solve the problems of aging deformation, oxidation and corrosion of the inner box, etc., to improve the durability, prolong the service life, and facilitate the transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

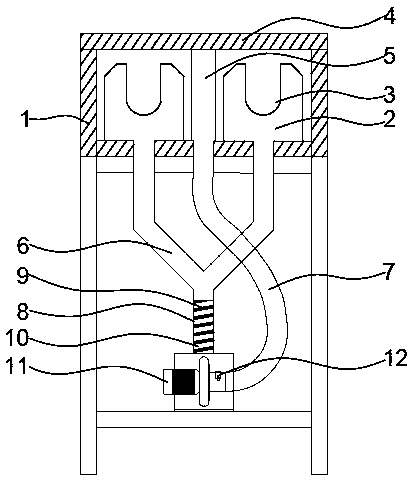

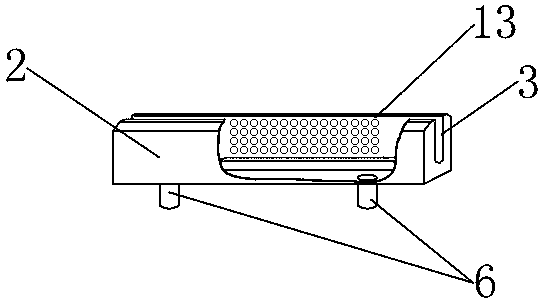

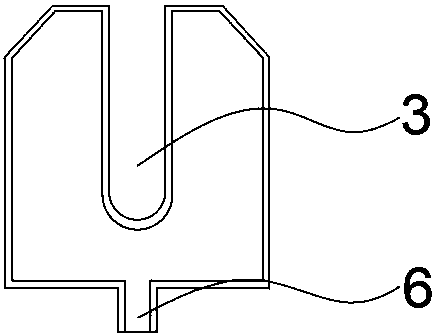

[0022] Such as Figure 1-5 As shown, the thermal cycle energy-saving drying equipment includes an outer box 1, and the outer box 1 is provided with a plurality of through holes 15 for allowing wet materials to pass through the outer box 1 and a plurality of inner boxes 2 arranged in the outer box 1. , the inner box 2 is provided with a groove 3 corresponding to the through hole 15 and allowing the material to pass through, the side of the groove 3 is provided with a plurality of air outlets 13, and the inner box 2 is provided with an air supply that communicates with the air outlet 13. The pipe 6 and the air supply pipe 6 are provided with an electromagnetic heating element 8 for heating the air in the air supply pipe 6. The electromagnetic heating element 8 includes a heating iron pipe 10 sleeved outside the air supply pipe 6 and surrounding the heating iron pipe 10. The outer wire 9 connected to the high-frequency power supply, the other end of the air supply pipe 6 is conne...

Embodiment 2

[0029] Such as Figure 1-5As shown, when the thermal cycle energy-saving drying equipment is working, after the power is turned on, the wire 9 of the electromagnetic heating element 8 is connected to the high-frequency power supply, and an alternating magnetic field is formed around the wire 9, and the heating iron pipe 10 cuts the alternating magnetic field, thereby generating heat Alternating eddy currents are generated in the iron pipe 10, and the eddy currents cause the iron atoms in the heating iron pipe 10 to move at high speed and irregularly. The atoms collide and rub against each other to generate heat energy, thereby heating the air inside. It is pumped into the inner box 2 through the air supply pipe 6, and the hot air is blown from the air outlet 13 on the side of the groove 3 to the groove 3. At this time, the wet material in the groove 3 is dried; the hot and humid air with a lower temperature after evaporation of water vapor It enters the exhaust box 5, and is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com