A kind of wear-resistant alloy layer based on high boron iron base and method for preparing composite wear-resistant parts

A technology of composite wear-resistant parts and wear-resistant alloys, used in metal processing equipment, coatings, manufacturing tools, etc., can solve the problems of low toughness, constraints, poor plasticity of Fe-B alloys, and achieve low brittleness, surface hardness and The effect of improved service life and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

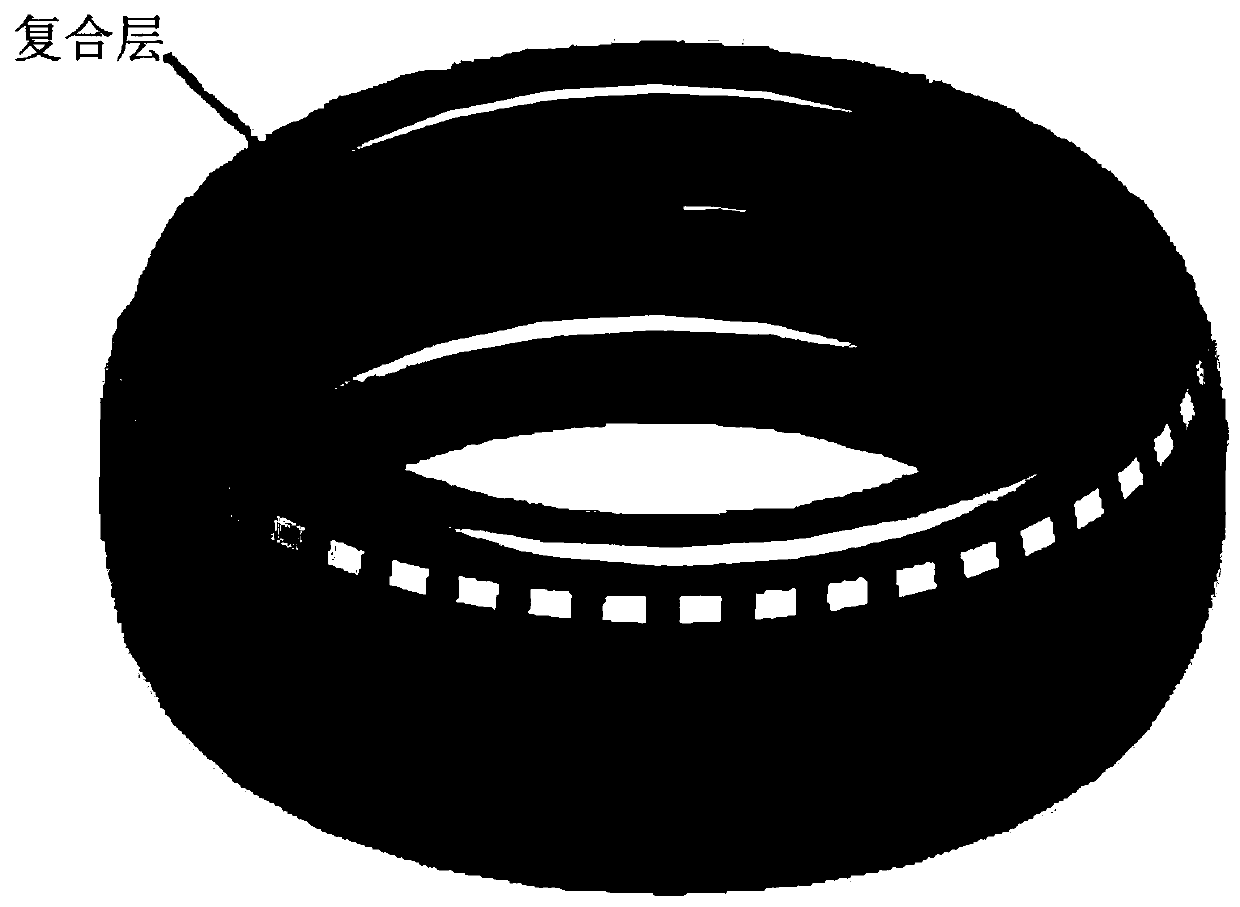

Image

Examples

Embodiment 1

[0040] 1) Mix the alloy powder with a particle size of 10-50 microns and the inorganic salt evenly at a mass ratio of 1:2.5, and apply it to the part of the casting that needs to be strengthened;

[0041] 2) preheating the coated casting in an oven, so that the alloy powder particles are connected to each other to form a pore-like prefabricated body;

[0042] 3) The metal liquid of high boron iron-based alloy material is poured by casting infiltration process. The pouring temperature is 1450°C. After cooling, it undergoes quenching and stress relief treatment. The quenching temperature is 1050°C, and the stress relief annealing temperature is 200°C to obtain high boron iron-based Crane drum.

Embodiment 2

[0044] 1) Mix the alloy powder with a particle size of 10-50 microns and the inorganic salt evenly at a mass ratio of 1:2.5, and apply it to the part of the casting that needs to be strengthened;

[0045] 2) Preheating the coated casting in an oven, so that the alloy powder particles are connected to each other to form a pore-like prefabricated body;

[0046] 3) The metal liquid of high boron iron-based alloy material is poured by cast infiltration process, the pouring temperature is 1550°C, after cooling, it is quenched and stress-relieved, the quenching temperature is 1180°C, and the stress-relief annealing temperature is 300°C to obtain high-boron iron-based alloy material Hoist the reducer reel.

Embodiment 3

[0048] 1) Mix the alloy powder with a particle size of 10-50 microns and the inorganic salt evenly at a mass ratio of 1:2, and apply it to the part of the casting that needs to be strengthened;

[0049] 2) Preheating the coated casting in an oven, so that the alloy powder particles are connected to each other to form a pore-like prefabricated body;

[0050] 3) The metal liquid of high boron iron-based alloy material is poured by casting infiltration process. The pouring temperature is 1450°C. After cooling, it undergoes quenching and stress relief treatment. The quenching temperature is 1050°C, and the stress relief annealing temperature is 200°C. After cooling, high boron is obtained. Iron-based cone-type grinding roller composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com