Environmentally-friendly polyurethane composite ink composition capable of adapting to ultra-high-speed printing and manufacturing method of composition

An ink composition and polyurethane technology, applied in the field of ink, can solve the problems of low ink printing viscosity, excessive solvent residue, easy ink sticking back, etc., and achieve the effects of good tinting strength, excellent composite strength, and strong printing adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

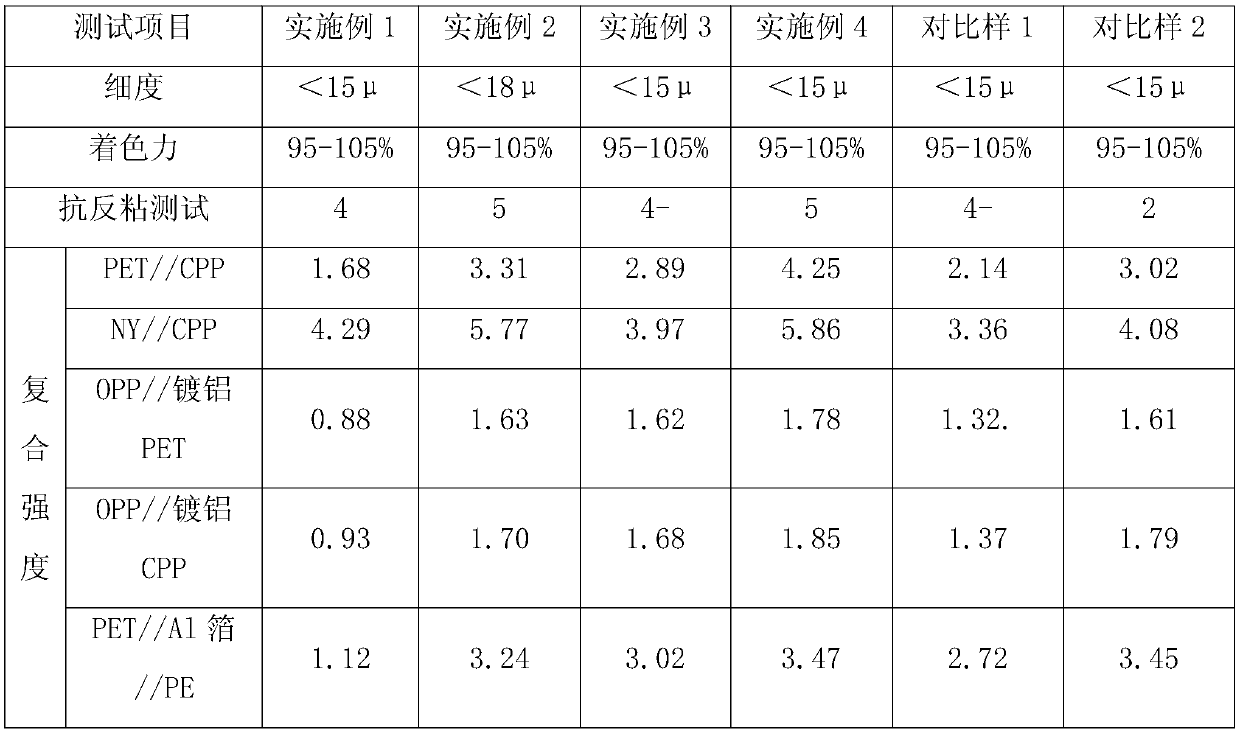

Examples

Embodiment 1

[0029] An environmentally friendly polyurethane composite ink composition suitable for high-speed printing, comprising the following raw materials: 30 parts of amide modified polyurethane resin, 15 parts of vinyl acetate resin, 5 parts of cellulose acetate propionate resin, 8 parts of pigments, and 0.5 parts of dispersant Parts, wax powder 0.5 parts, matte powder 0.2 parts, antistatic agent 0.3 parts, adhesion enhancer 1.5 parts, propyl acetate 15 parts, ethyl acetate 8 parts, butyl acetate 10 parts, isopropanol 5 parts, propylene glycol 5 parts of monomethyl ether and 1 part of propylene glycol monomethyl ether acetate. The amide-modified polyurethane resin has an average molecular weight of 30000, a viscosity of 1200 mPa·s, and a solid content of 31%. The chlorinated vinegar resin solid in the chlorinated vinegar resin solution is a tribasic hydroxychlorinated vinegar with a weight percentage of 25%, propyl acetate with a weight percentage of 35%, and ethyl acetate with a wei...

Embodiment 2

[0036] An environmentally friendly polyurethane composite ink composition suitable for high-speed printing, comprising the following raw materials: 25 parts of amide-modified polyurethane resin, 5 parts of vinyl acetate resin, 3 parts of cellulose acetate propionate resin, 33 parts of pigments, and 0.2 parts of dispersant Parts, wax powder 0.5 parts, matte powder 0.5 parts, antistatic agent 0.8 parts, adhesion enhancer 1 part, propyl acetate 12 parts, ethyl acetate 5 parts, butyl acetate 10 parts, isopropanol 3 parts, propylene glycol 3 parts of monomethyl ether and 1 part of propylene glycol monomethyl ether acetate. The average molecular weight of the amide-modified polyurethane resin is 25000, the viscosity is 650mpa·s, and the solid content is 30%; the solid content of the chlorinated vinegar resin in the chlorinated vinegar resin solution is ternary hydroxychlorinated vinegar, and the weight percentage is 20. %, the weight percentage of propyl acetate is 60%, the weight pe...

Embodiment 3

[0043] An environmentally friendly polyurethane composite ink composition suitable for high-speed printing, comprising the following raw materials: 32 parts of amide-modified polyurethane resin, 10 parts of vinyl acetate resin, 8 parts of cellulose acetate propionate resin, 9 parts of pigments, and 1 dispersant Parts, wax powder 1 part, matte powder 0.5 parts, antistatic agent 1 part, adhesion enhancer 0.5 parts, propyl acetate 10 parts, ethyl acetate 7 parts, butyl acetate 10 parts, isopropanol 3 parts, propylene glycol 3 parts of monomethyl ether and 3 parts of propylene glycol monomethyl ether acetate. The amide-modified polyurethane resin has an average molecular weight of 30000, a viscosity of 1500 mPa·s, and a solid content of 35%. The chloroacetate resin solids in the chloroacetate resin solution are trivalent hydroxy chloroacetate, the weight percentage is 35%, the weight percentage of propyl acetate is 40%, and the weight percentage of ethyl acetate is 25%; The molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com