Intelligent powdering and selling robot and method

A sales robot and intelligent technology, applied in the directions of instruments, bottle/container caps, and caps to tightly cover containers, etc., can solve the problems of unmanned powder processing, high safety and hygiene requirements in food processing, and high labor cost of powder grinding methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0018] In the technical process of researching the intelligent powder-making and selling robot and method, the technicians of the present invention found that the existing powder-making machines need to manually complete the processes of material selection, weighing, powder-making, packaging, etc., which greatly wastes labor costs and is difficult to ensure food processing hygiene. Safety, in order to solve this problem, technicians use the intelligent powder sales method to solve it.

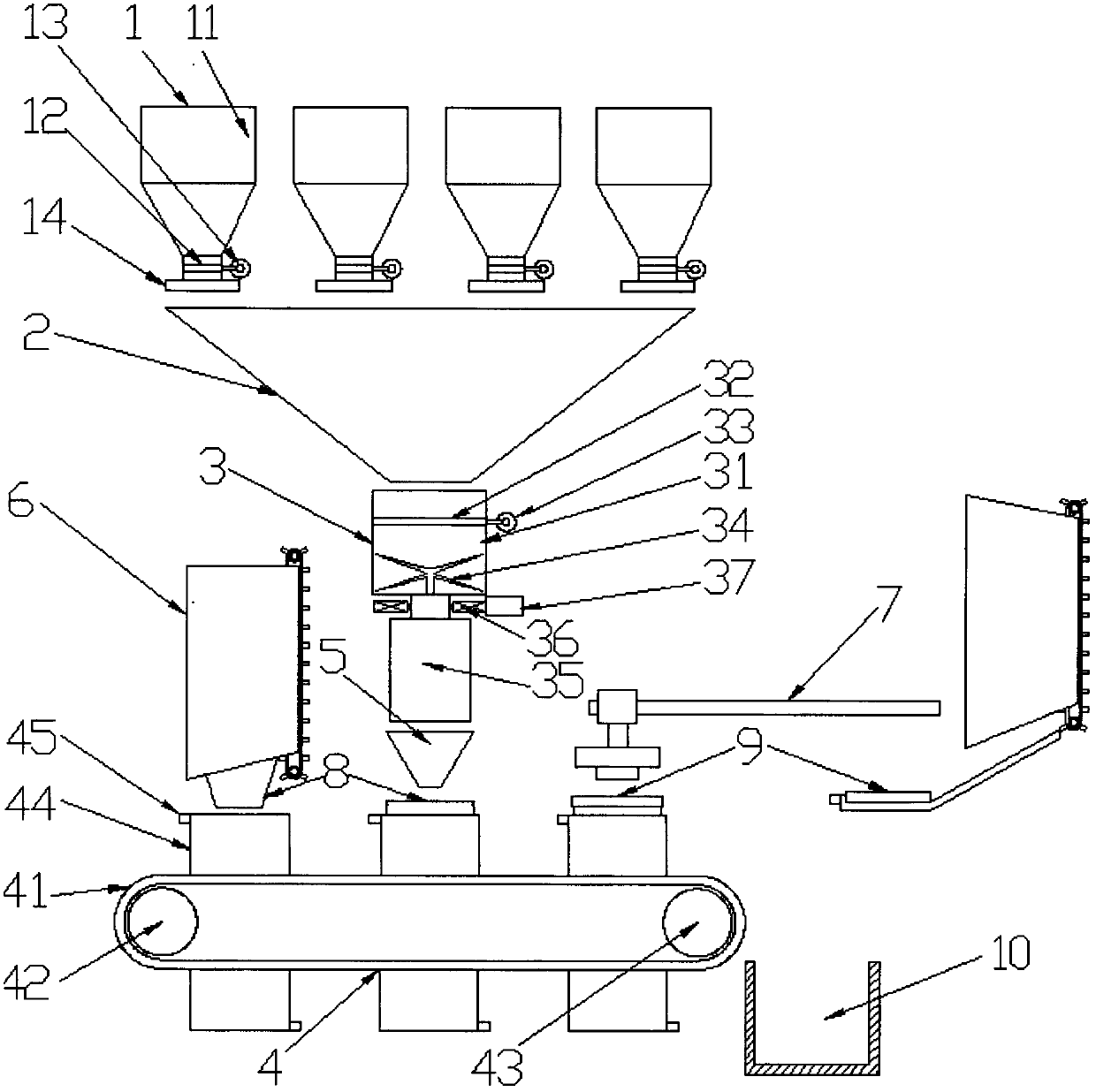

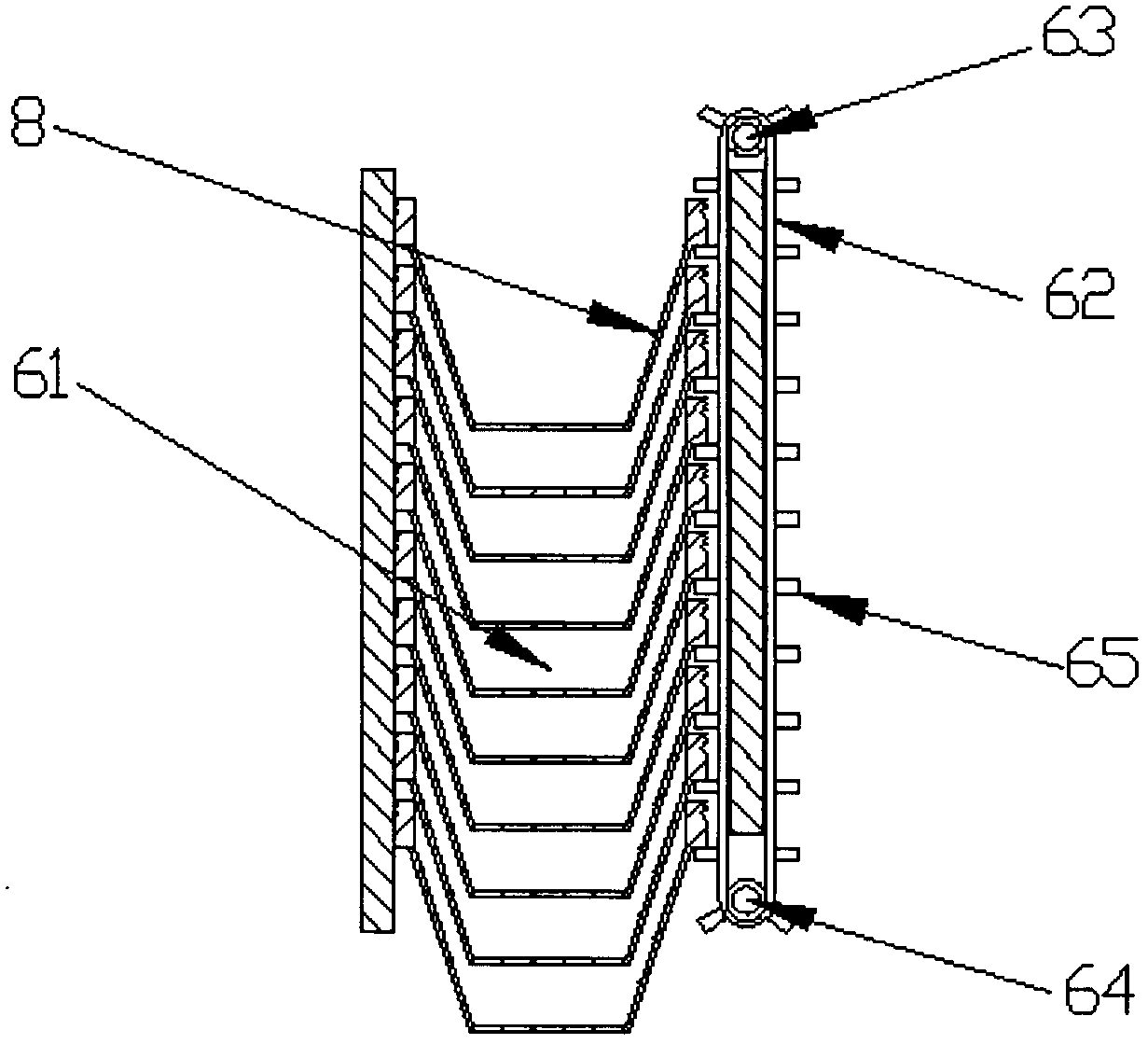

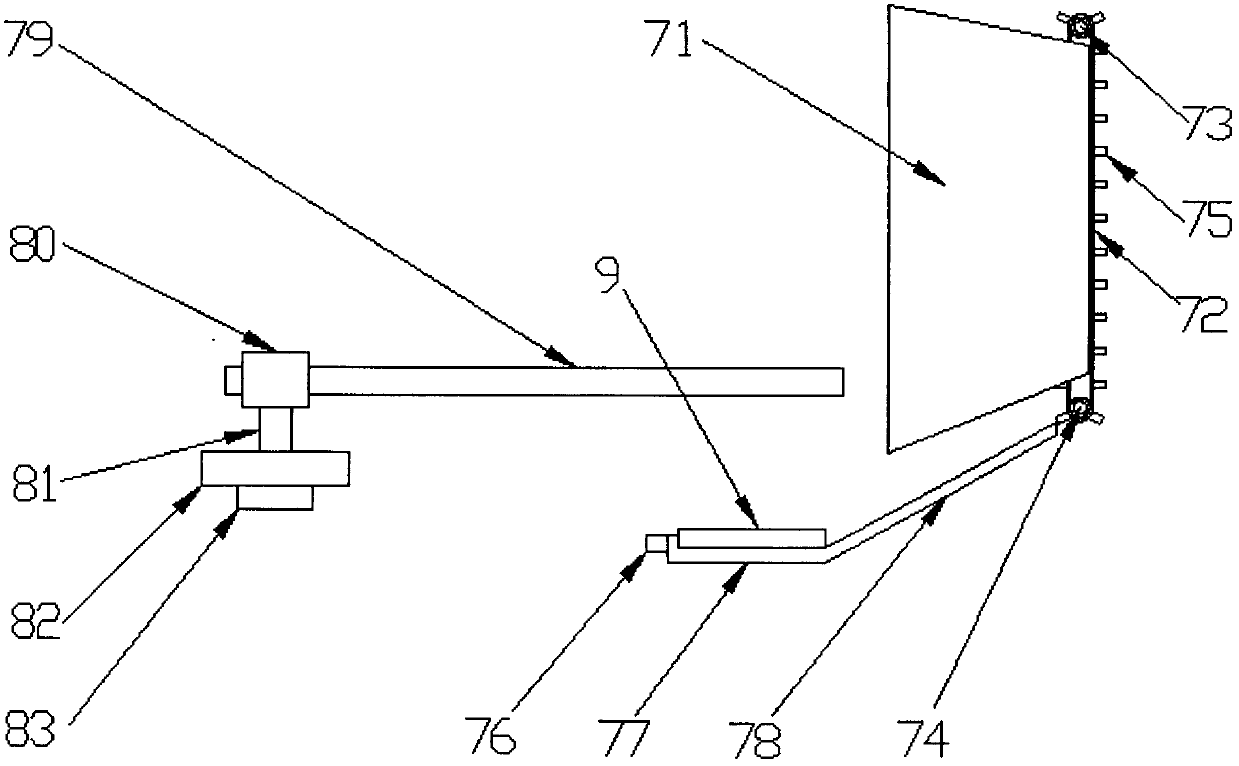

[0019] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , The structural schematic diagram of the intelligent powder making and selling robot of the present invention includes a silo device 1, a collecting hopper 2, a powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com