A Processing Technology of Oil Hydraulic Jack Rolling to Remove the Fast Port of Pump Core

A processing technology and jacking technology, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of scratching the sealing ring, slow processing efficiency, and the sealing performance of the sealing ring, etc., to protect the annular notch, The effect of improving processing efficiency and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

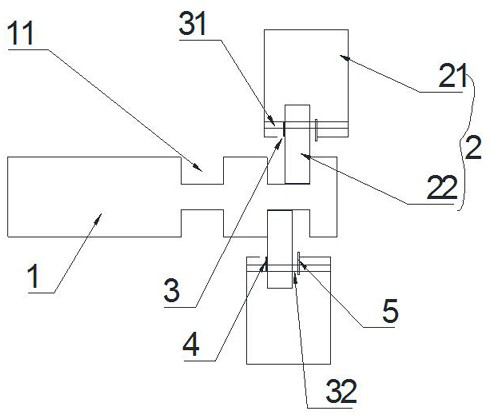

[0020] Such as figure 1 It is a specific embodiment of the present invention, which specifically includes the following steps: S1, forming the pump core 1 by blanking the sheet material, and the end of the pump core 1 is extruded to form an annular notch 11;

[0021] S2. Insert the pump core 1 into the tooling fixture of the machine tool, and the annular notch 11 is located on the outside of the tooling fixture;

[0022] S3. Take two rolling knives 2 and align them with the inner walls on both sides of the same annular notch 11, and feed the two rolling knives 2 to the inside of the annular notch 11 synchronously, and the fixture drives the pump core 1 Rotating, the two rolling cutters 2 simultaneously roll and grind the inner walls of the inner sides of the annular notch 11 .

[0023] In the present invention, during the rotation process of the pump core 1 driven by the fixture, two rolling cutters 2 are used to roll and polish the two inner sidewalls of the annular notch 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com