Intelligent smell array sensor and manufacturing method

An array sensor and odor sensor technology, applied in the field of odor sensors, can solve the problems of low sensitivity, high cost, poor selectivity, etc., and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

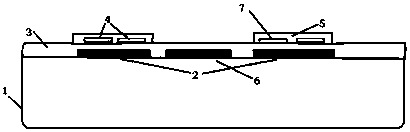

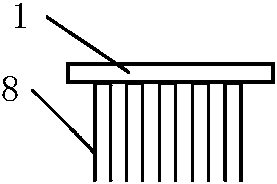

[0024] A kind of intelligent olfactory smell array sensor, its composition comprises: chip 1, described chip 1 upper surface is provided with electric insulation layer 3, described electric insulation layer 3 is provided with heater 2 and temperature detector 6, described The temperature measuring device 6 is arranged between the heaters 2, and the upper surface of the electrical insulating layer 3 is provided with different types of odor sensor film layers 5, and the different types of odor sensor film layers 5 are arranged in an array, and the described Different types of odor sensors 7 are embedded in the odor sensor film layer 5, sensor electrodes 4 are arranged on the different types of odor sensors 7, and several electrode lead posts 8 are arranged on both sides of the upper surface of the electrical insulating layer 3.

Embodiment 2

[0026] According to an intelligent olfactory-smell array sensor described in Embodiment 1, several electrode lead posts 8 are used to support the chip 1 and serve as conductive leads.

Embodiment 3

[0028] According to the manufacturing method of the intelligent olfactory smell array sensor described in embodiment 1 or 2,

[0029] First: use microelectronic planar technology lithography, diffusion, and evaporation technology to manufacture heaters and temperature detector electrodes on the substrate;

[0030] Second: covering the above electrodes with an electrical insulating layer;

[0031] Third: Manufacturing electrode leads of various types of sensors on the electrical insulating layer;

[0032] Fifth: Manufacture different types of odor sensor films in the limited areas on the electrode leads of the above-mentioned various types of sensors;

[0033] Sixth: Nano-membrane layers of various types of odor sensors, so that the particles have the highest surface area / volume ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com