Membrane type monolayer cell sheet manufacturing machine and sheet manufacturing method thereof

A single-layer cell and tableting machine technology, applied in the field of pathological diagnostic equipment, can solve the problems of small throughput of membrane-type preparation samples, no cells in the center of the sampling area, unstable preparation effect, etc., which is beneficial to DNA staining and equipment. Small, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

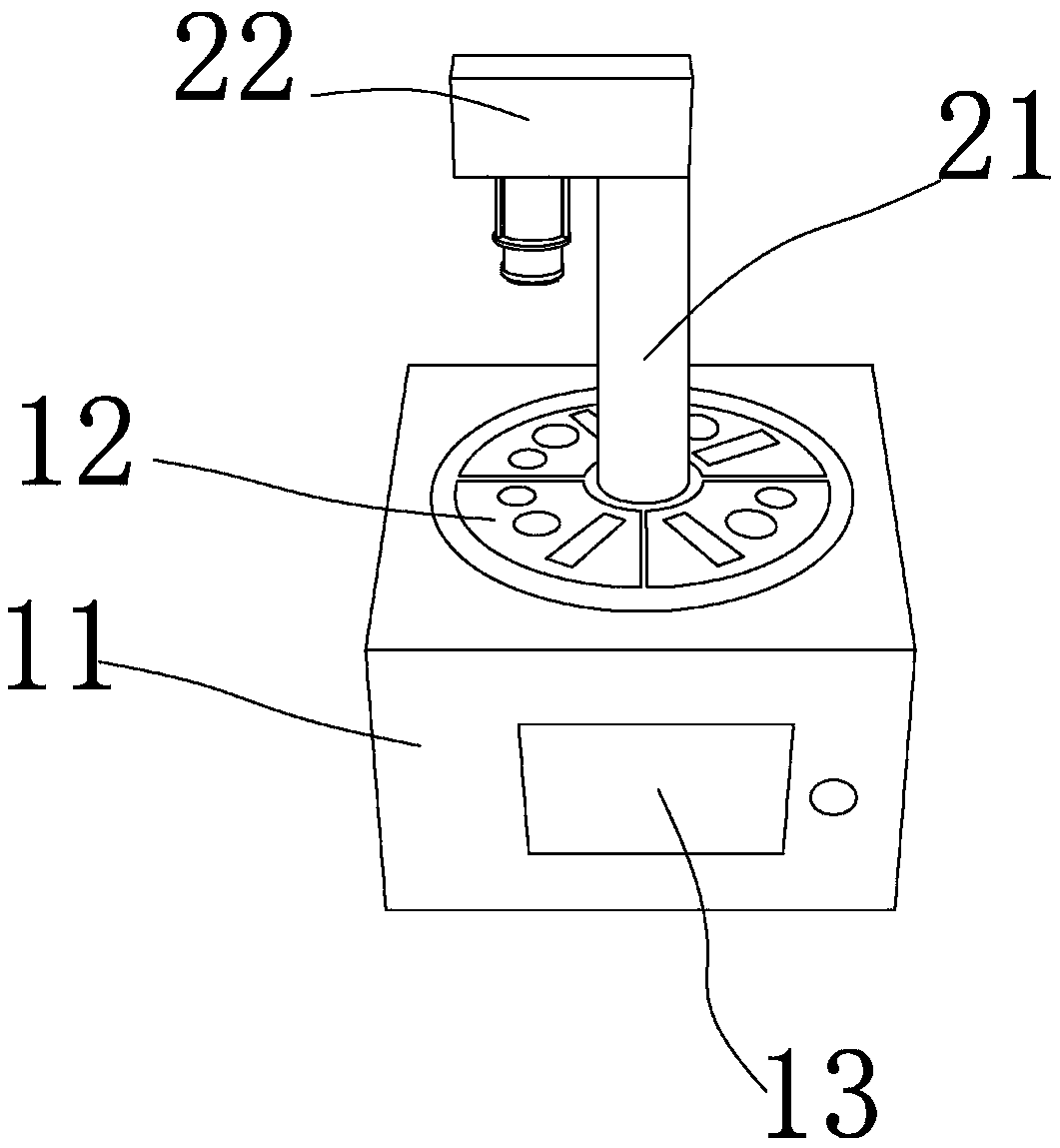

Embodiment 1

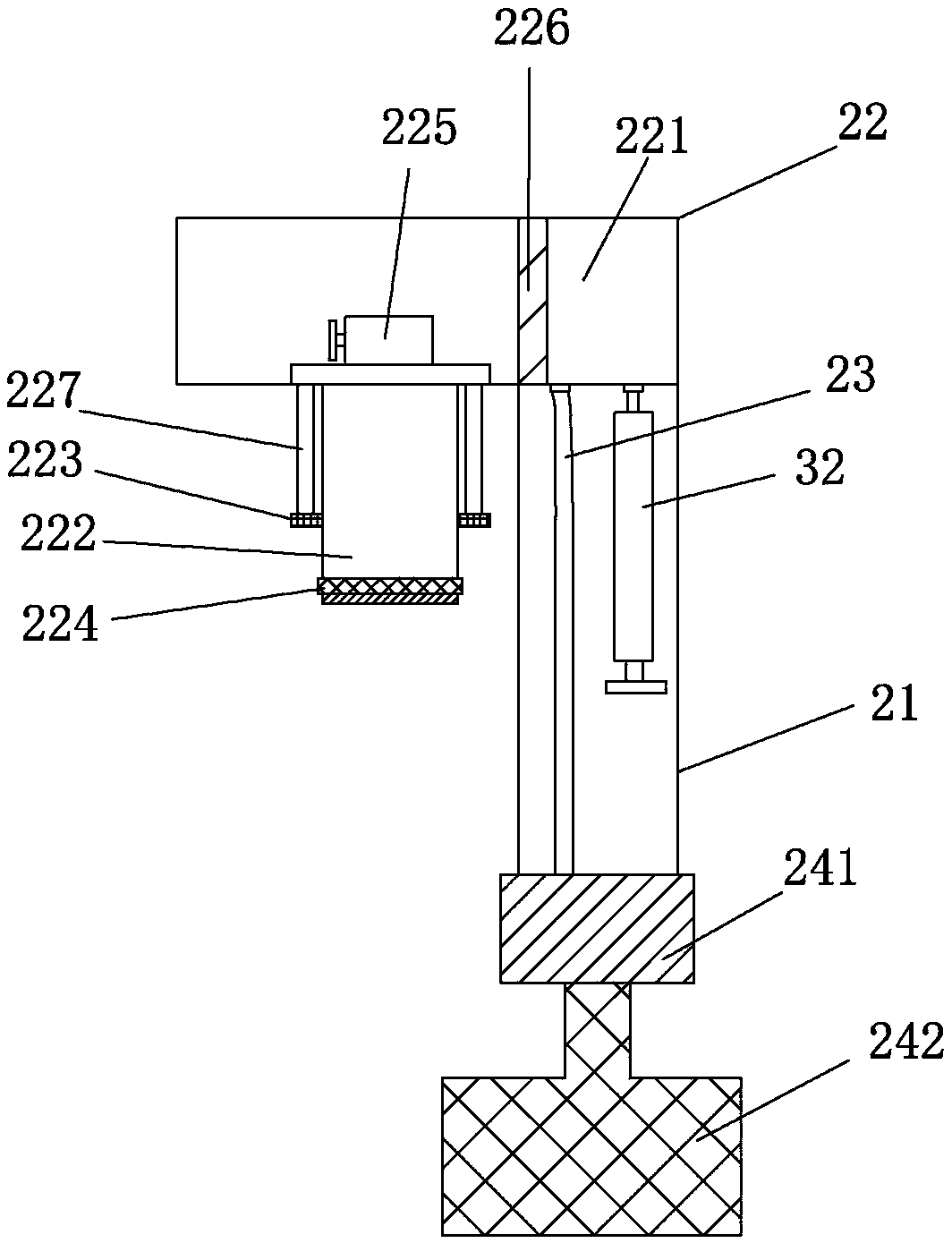

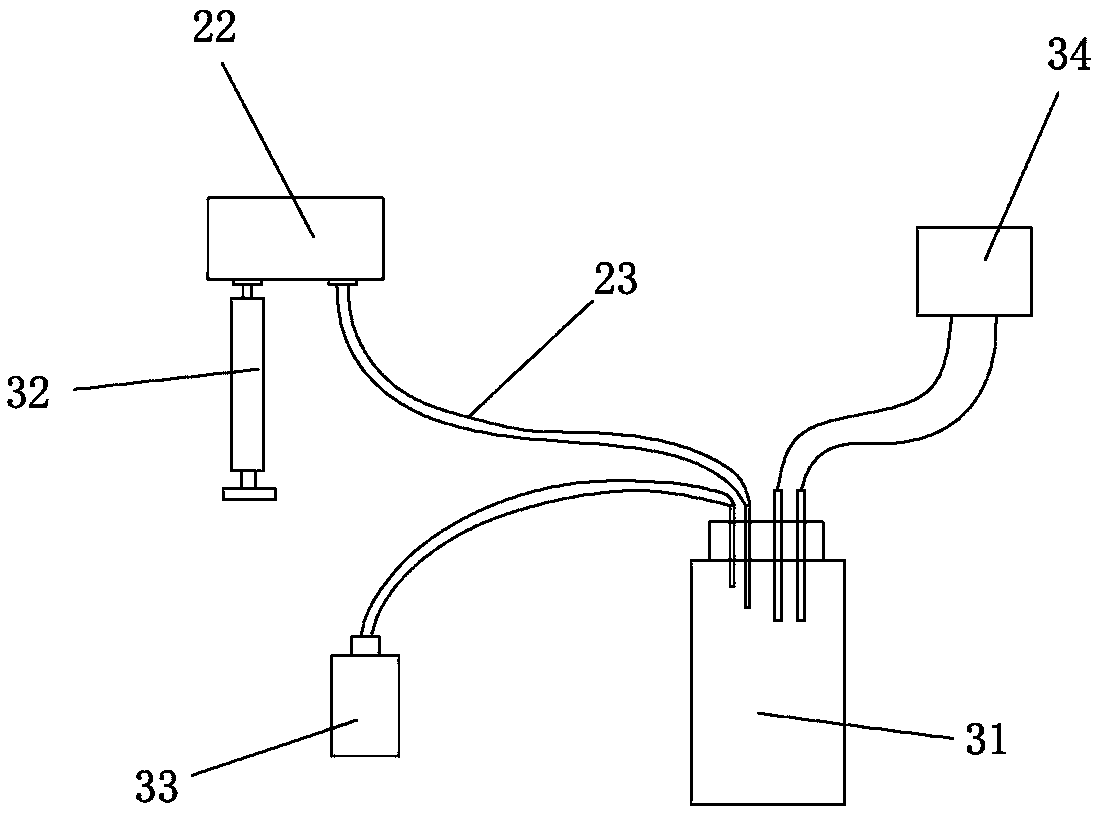

[0060] Place the sample bottle containing the cell sample on the shaker, shake and mix, unscrew the cap, put 1 cervical sample bottle into the sample bottle slot of the fixed plate (specification 1), and put the labeled One glass slide and one filter cartridge are respectively put into the slide slot and the film cartridge slot of the same fixed disk.

[0061] Insert the fixed disk on the bearing platform, select program 1, the number of specimens 1, and click run.

[0062] Reset the mechanical arm, turn it to the top of the filter cartridge slot, then move the robot arm down, pull the filter cartridge, and move up; turn it to the sample bottle slot again, and move the robotic arm down until the filter cartridge is immersed in the sample. After blowing the sample, The cells are sucked and filtered onto the filter membrane, the robotic arm moves up, the membrane cartridge loading device rotates 180°, and the remaining liquid is aspirated and reset; it is rotated again to the top of ...

Embodiment 2

[0064] Place the sample bottle containing the cell sample on the shaker, shake and mix, unscrew the cap, put a cervical sample bottle into the sample bottle slot of the fixed plate (specification 2), and put the labeled Put 2 slides and 1 filter cartridge into the slide slot and the membrane cartridge slot of the same fixed disk;

[0065] Embed the fixed disk on the bearing platform, select program 2, number of specimens 1, and click run;

[0066] Reset the mechanical arm, turn it to the top of the filter cartridge slot, then move the robot arm down, pull the filter cartridge, and move up; turn it to the sample bottle slot again, and move the robotic arm down until the filter cartridge is immersed in the sample. After blowing the sample, The cells are sucked and filtered onto the filter membrane, the robotic arm moves up, the membrane cartridge loading device rotates 180°, and the remaining liquid is aspirated and reset; it is rotated again to the top of the slide card slot, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com