Electric heating rotary dryer

A rotary dryer and dryer technology, applied in drying chamber/container, dry solid material, non-progressive dryer, etc., can solve the problems of increasing production cost, reducing production efficiency, affecting product quality, etc., and achieve the improvement of production efficiency , labor saving, good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

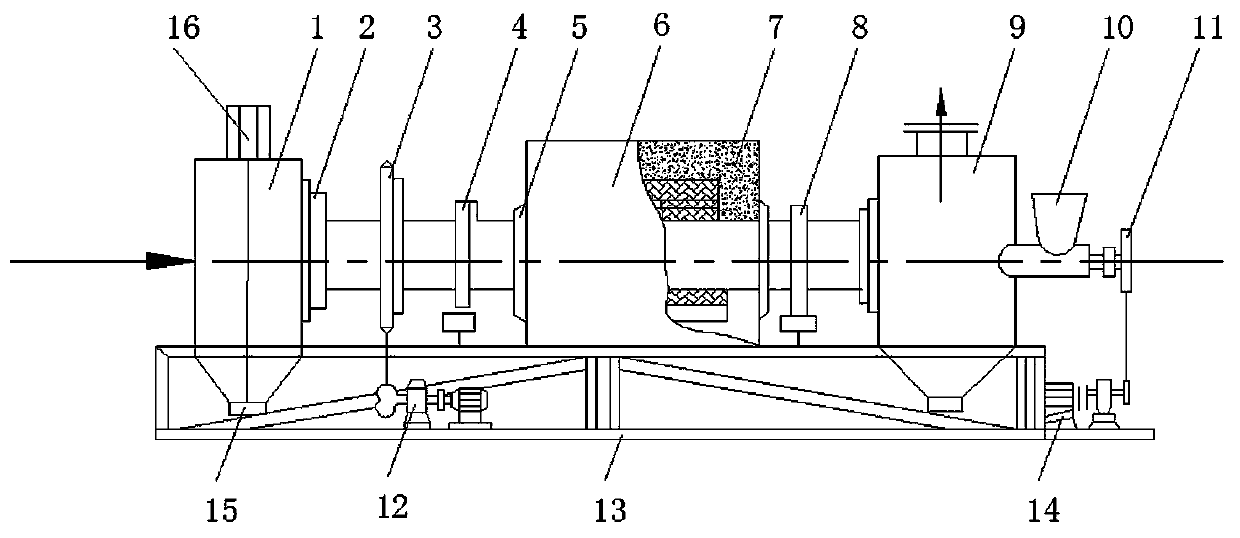

[0026] like figure 1 The shown electrothermal rotary dryer includes a bracket 13, on which a feeding device 10, a gas-liquid recovery chamber 9, a dryer body 5, a material collecting device 1 and a crushing unloading device are sequentially arranged on the bracket 13 from the feed end to the discharge end. Material mechanism 15;

[0027] The two ends of the dryer body 5 are respectively coaxially connected with the feeding device 10 and the gas-liquid recovery chamber 9, and a material axial conveying mechanism 11 is arranged inside, a material collecting device 1 and a crushing and unloading mechanism 15 are coaxially arranged, and the dryer body 5 The discharge port communicates with the material collection device 1;

[0028] The outer side of the dryer body 5 is coaxially provided with an electric heater body 6 for heating the dryer body 5;

[0029] It also includes a driver 3 coaxially arranged with the dryer body 5 and a first drive motor 12, the output end of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com