500mpa grade hot-rolled automotive structural steel plate with good weldability and manufacturing method

A technology for welding performance and automobile structure, applied in the field of hot-rolled steel strip production, can solve the problems affecting the application and promotion of materials, poor weldability of high-strength steel, etc., and achieve the effects of green manufacturing, excellent welding performance and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

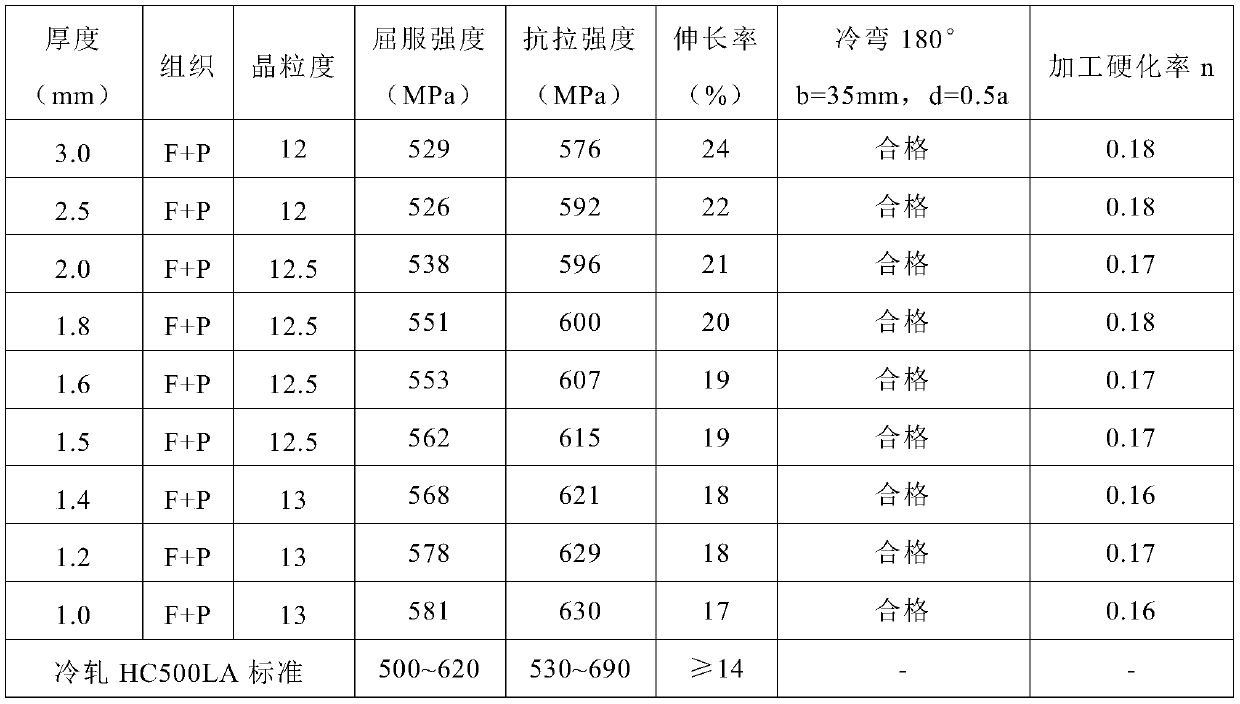

Embodiment 1

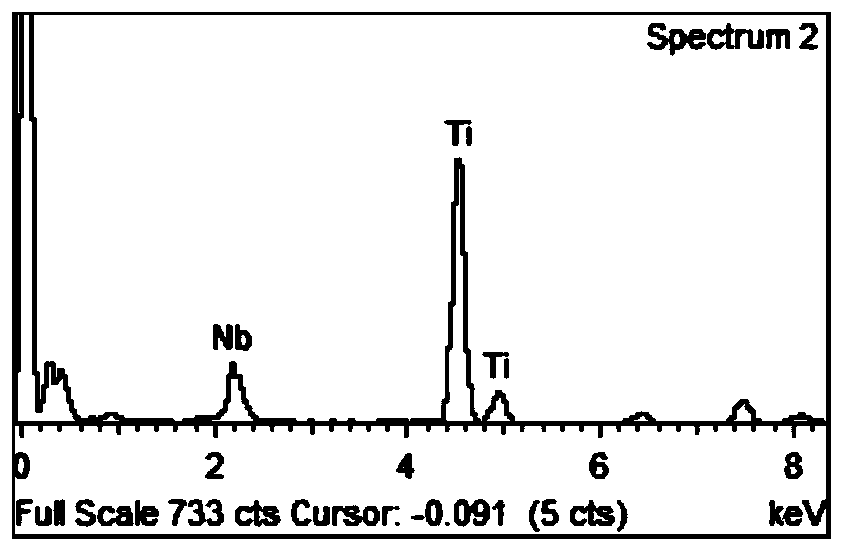

[0039] The 500MPa grade of this embodiment has the hot-rolled automobile structural steel plate of good weldability, adopts " low carbon, low silicon, low manganese " Nb-Ti microalloy composition system to produce, and each element chemical composition mass percentage wt% is controlled as follows: C : 0.05%, Si: ≤0.07%, Mn: 1.05%, S: ≤0.005%, P: ≤0.015%, Nb: 0.036%, Ti: 0.035%, N: ≤40ppm, Als: 0.025~0.050%;

[0040] Its manufacturing method comprises the following steps:

[0041] 1) Smelting

[0042] According to the composition and weight percentage, it is uniformly mixed to form molten steel, and the deep desulfurization pretreatment-converter steelmaking-LF-RH process is used for smelting;

[0043] Hot metal desulfurization pretreatment requirements S: ≤0.005%, converter molten steel smelting requirements C 0.05%, tapping temperature at 1690°C; deoxidation and slagging in LF furnace, leaving station temperature ≥1653°C; molten steel enters RH furnace, Decarburization, deo...

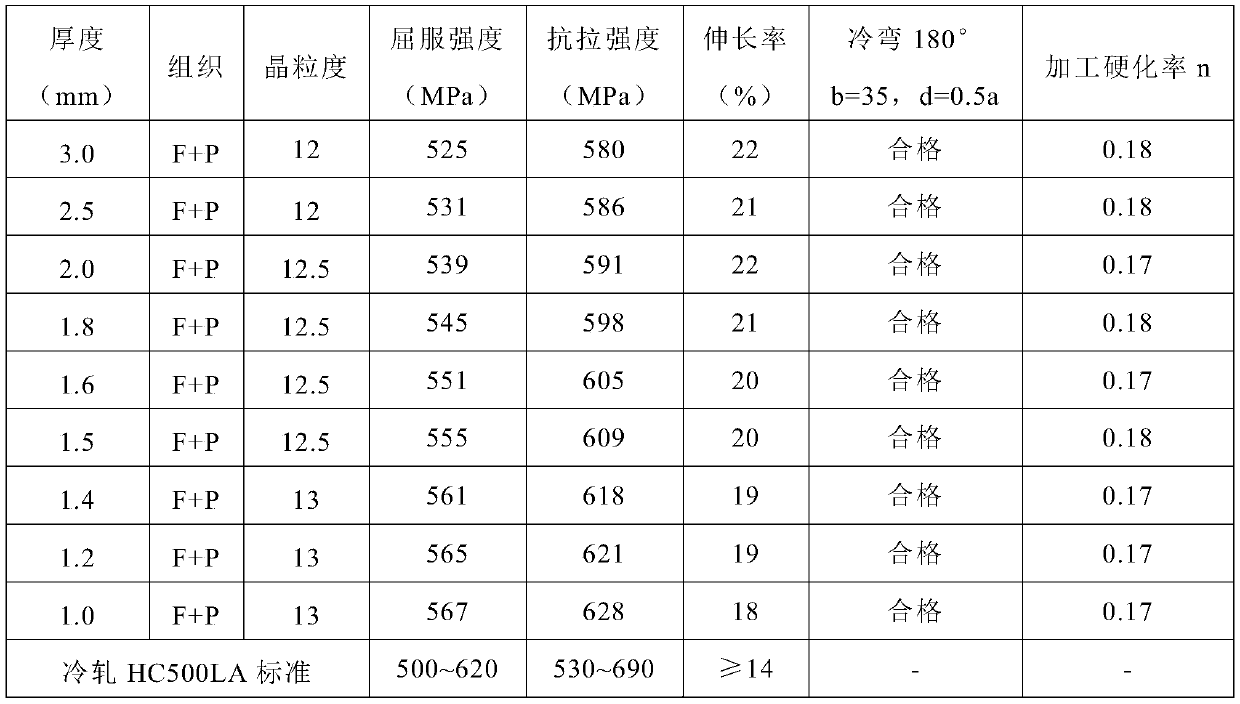

Embodiment 2

[0063] The 500MPa grade of this embodiment has the hot-rolled automobile structural steel plate of good weldability, adopts " low carbon, low silicon, low manganese " Nb-Ti microalloy composition system to produce, and each element chemical composition mass percentage wt% is controlled as follows: C : 0.055%, Si: ≤0.08%, Mn: 1.10%, S: ≤0.004%, P: ≤0.015%, Nb: 0.036%, Ti: 0.037%, N: ≤40ppm, Als: 0.025~0.050%;

[0064] Its manufacturing method comprises the following steps:

[0065] 1) Smelting

[0066] According to the composition and weight percentage, it is uniformly mixed to form molten steel, and the deep desulfurization pretreatment-converter steelmaking-LF-RH process is used for smelting;

[0067] Hot metal desulfurization pretreatment requirement S: ≤0.004%, converter molten steel smelting requirement C is 0.055%, tapping temperature at 1674°C; deoxidation and slagging in LF furnace, leaving station temperature ≥1635°C; molten steel enters RH furnace, Decarburization, ...

Embodiment 3

[0087] The 500MPa grade of this embodiment has the hot-rolled automobile structural steel plate of good weldability, adopts " low carbon, low silicon, low manganese " Nb-Ti microalloy composition system to produce, and each element chemical composition mass percentage wt% is controlled as follows: C : 0.055%, Si: ≤0.07%, Mn: 1.15%, S: ≤0.003%, P: ≤0.015%, Nb: 0.036%, Ti: 0.038%, N: ≤40ppm, Als: 0.025~0.050%;

[0088] Its manufacturing method comprises the following steps:

[0089] 1) Smelting

[0090] According to the composition and weight percentage, it is uniformly mixed to form molten steel, and the deep desulfurization pretreatment-converter steelmaking-LF-RH process is used for smelting;

[0091] Hot metal desulfurization pretreatment requires S ≤ 0.003%, converter molten steel smelting requires C to be 0.055%, and the tapping temperature is 1680°C; deoxidation and slag formation in the LF furnace, the leaving station temperature is ≥ 1645°C; molten steel enters the RH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com