A method for pressure-controlled dry bacterial cellulose to restore the original three-dimensional network structure

A bacterial cellulose and network structure technology, applied in the field of biological materials, can solve the problems of unfavorable transportation, poor mechanical properties, complicated process, etc., and achieve the effects of easy storage and transportation, high mechanical properties and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

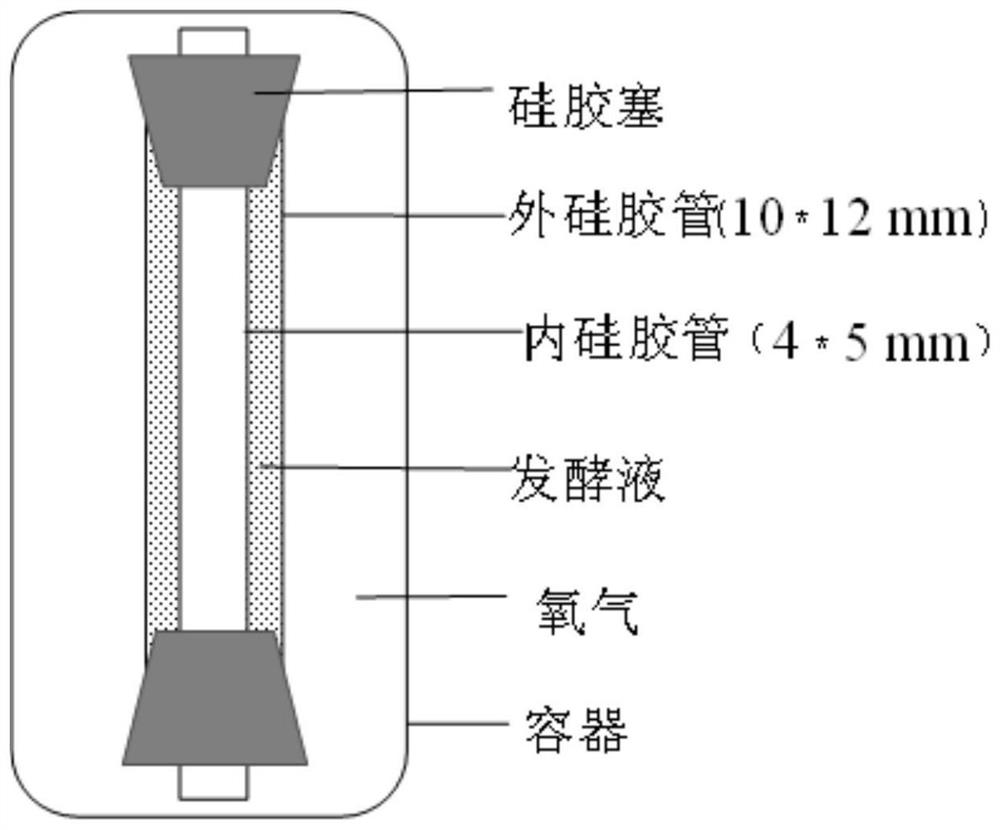

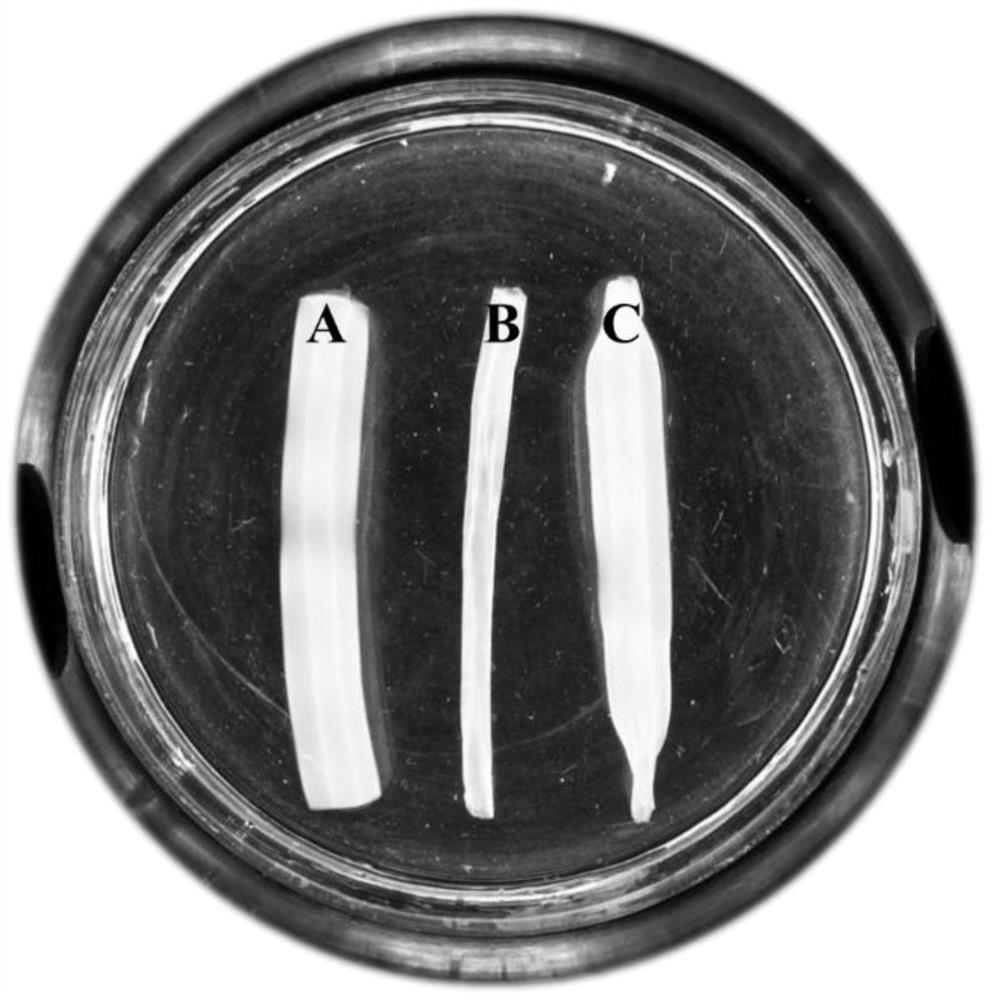

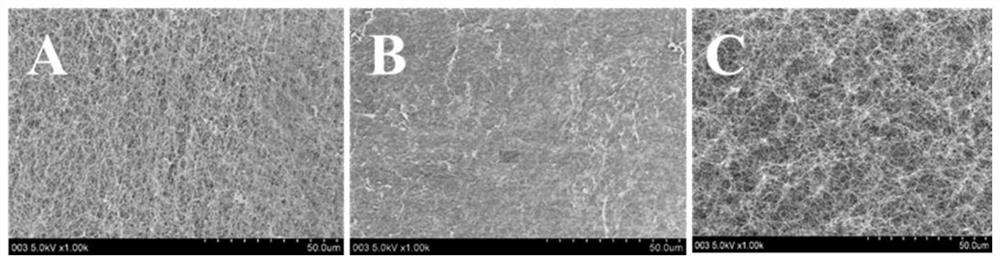

[0030] (1) Inject the culture solution containing Gluconacetoacetobacter xylinum into the sterilized double silica gel tube reaction device (such as figure 1 shown) in the cavity of 30°C for 7 days, a BNC hydrogel tube with a length of 100mm, an inner diameter of 5mm, and an outer diameter of 10mm was obtained, which was recorded as a D-BNC tube, and then used in a water bath at 80°C The concentration was 1% NaOH alkali boiling 3 times, 4 hours each time, and repeated replacement with deionized water to neutrality to obtain the purified D-BNC tube.

[0031] (2) Put the purified D-BNC tube obtained in step (1) on a polytetrafluoroethylene tube with an outer diameter of 5 mm and a length of 100 mm, evaporate and dry the water, dry it by air blast to constant weight, and remove the polytetrafluoroethylene tube. Vinyl fluoride tubing to get dry D-BNC tubing.

[0032] (3) Connect one end of the dry D-BNC tube to the pressure gauge, and the other end to the water pump, and inject ...

Embodiment 2

[0035] (1) Inoculate the culture medium containing Gluconacetoacetobacter xylinum ATCC 23770 into a 250mL Erlenmeyer flask containing 100mL of culture medium, and culture it statically at 30°C for 7 days to obtain a BNC membrane. Boil with 1% NaOH alkali for 3 times, each time for 2 hours, and then repeatedly replace it with deionized water to neutrality to obtain a purified BNC membrane.

[0036] (2) Spread the purified BNC film obtained in step (1) on a polytetrafluoroethylene plate, perform water evaporation and drying, and blow dry to constant weight to obtain a dry BNC film.

[0037] (3) Fix the dry BNC membrane on such as Figure 5 On the device shown, DMEM (Dulbecco's Modified Eagle Medium) high-glucose medium was applied vertically on the dry BNC membrane with a pressure of 0.05 MPa, and the membrane gradually expanded. After 5 minutes, the membrane was removed to restore the three-dimensional nanofiber network structure And the DMEM high-glucose medium is filled with...

Embodiment 3

[0040] (1) Inject the nutrient solution containing Kombucha into a sterilized double silica gel tube reaction device (such as Figure 6 shown) in the cavity of 30°C for 5 days, a BNC hydrogel tube with a length of 100mm, an inner diameter of 3mm, and an outer diameter of 8mm was obtained, which was recorded as a D-BNC tube, and then used in a water bath at 80°C The concentration is 1% NaOH alkali boiling 3 times, 2 hours each time, and repeatedly replaced with deionized water to neutrality to obtain a purified D-BNC tube.

[0041](2) Put the purified D-BNC tube obtained in step (1) on a polytetrafluoroethylene tube with an outer diameter of 3 mm and a length of 100 mm, evaporate and dry the water, dry it by air blast to constant weight, and remove the polytetrafluoroethylene tube. Vinyl fluoride tubing to get dry D-BNC tubing.

[0042] (3) Connect one end of the dry D-BNC tube to the pressure gauge, and the other end to a syringe filled with blood, which is rabbit blood with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| suture strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com