Ammonia nitrogen removal agent and method for treating sewage by utilizing agent

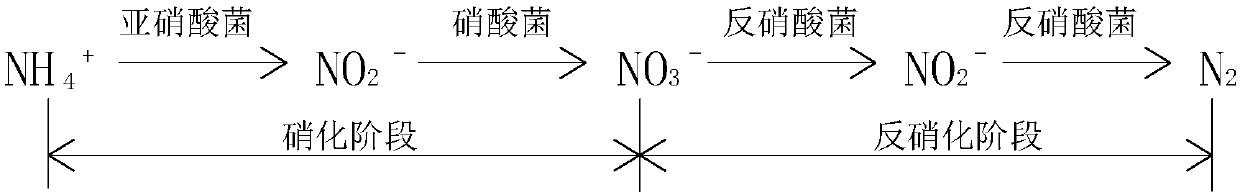

A chemical treatment, ammonia nitrogen technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve problems such as large fluctuations in water quality, system impact, system impact collapse, etc., to achieve enhanced ammonia nitrogen Treatment effect, improvement of impact resistance, and effect of promoting growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

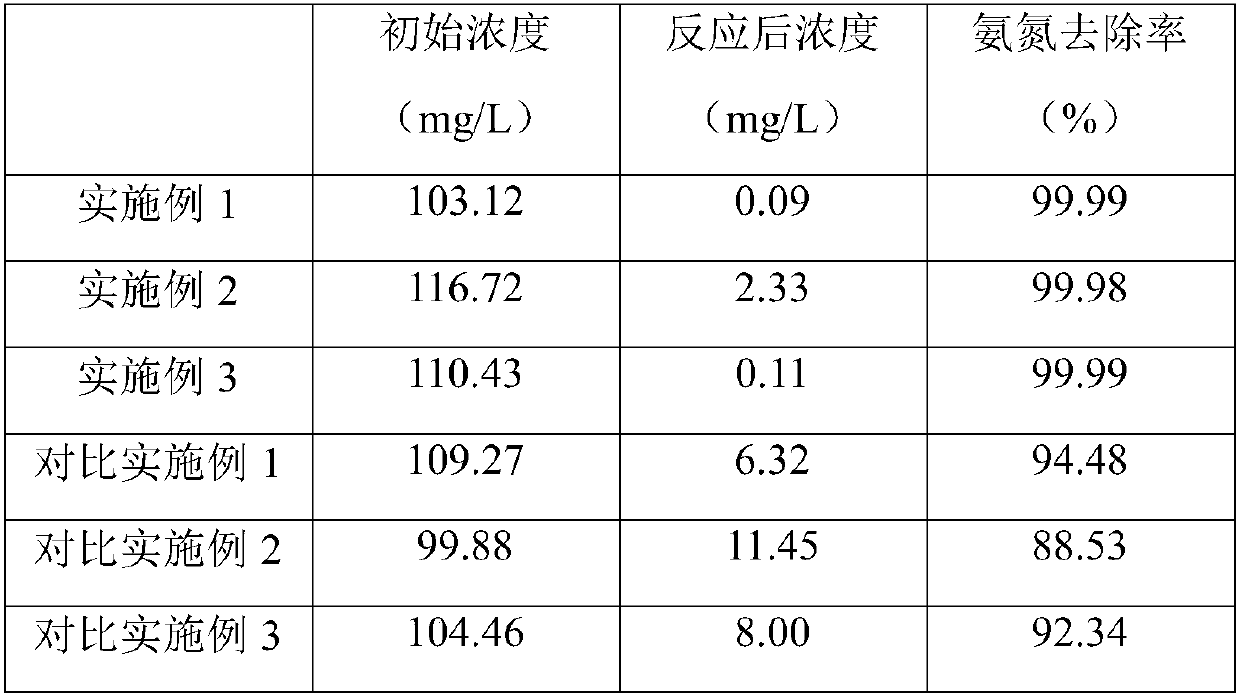

Embodiment 1

[0023] 1), adding alkali and polyaluminum chloride flocculant to the wastewater containing ammonia nitrogen to adjust the pH of the wastewater to 7.5 and flocculation and sedimentation treatment, and filter;

[0024] 2), add 86ppm of ammonia nitrogen removal agent to the wastewater for removing suspended particles and stir well, add coconut oil fatty acid diethanolamide 5ppm in the stirring process, ammonia nitrogen removal agent includes 8 parts of Arthrobacter globosa, 15 parts of denitrification paracoccus, 10 parts of Bacillus subtilis, 8 parts of Nocardia, 15 parts of Nitrobacter victoria, 20 parts of Pseudomonas K5020, 2 parts of Pseudomonas TR220 and 2 parts of snail stock solution; 2 times a day, 86ppm each time;

[0025] 3) Measure the ammonia nitrogen content in the waste water. When the content reaches 12 mg / l, the waste water is lifted into the ammonia nitrogen treatment device with a steam-water mixing pump, and then the separation device is started. The ammonia ni...

Embodiment 2

[0028] 1), adding alkali and polyaluminum chloride flocculant to the wastewater containing ammonia nitrogen to adjust the pH of the wastewater to 8.5 and flocculation and sedimentation treatment, and filter;

[0029] 2), add 200ppm of ammonia nitrogen removal agent to the wastewater for removing suspended particles and stir well, add coconut oil fatty acid diethanolamide 10ppm in the stirring process, ammonia nitrogen removal agent includes 10 parts of Arthrobacter globosa, 20 parts of denitrification paracoccus, 12 parts of Bacillus subtilis, 10 parts of Nocardia, 20 parts of Nitrobacter victoria, 25 parts of Pseudomonas K50, 25 parts of Pseudomonas TR2 and 5 parts of snail stock solution; 3 times a day, 200ppm each time ;

[0030] 3) Measure the ammonia nitrogen content in the waste water. When the content reaches 15 mg / l, the waste water is lifted into the ammonia nitrogen treatment device with a steam-water mixing pump, and then the separation device is started. The ammoni...

Embodiment 3

[0033] 1), adding alkali and polyaluminum chloride flocculant to the wastewater containing ammonia nitrogen, adjusting the pH of the wastewater to 8 and flocculation and sedimentation treatment, and filtering;

[0034] 2), add 140ppm of ammonia nitrogen removal agent to the wastewater for removing suspended particles and stir well, add coconut oil fatty acid diethanolamide 8ppm in the stirring process, ammonia nitrogen removal agent includes 9 parts of Arthrobacter globosa, 18 parts of denitrifying paracoccus, 11 parts of Bacillus subtilis, 9 parts of Nocardia, 16 parts of Nitrobacter victoria, 22 parts of Pseudomonas K50, 3 parts of Pseudomonas TR223 and 3 parts of snail stock solution; 3 times a day, 140ppm each time;

[0035] 3) Measure the ammonia nitrogen content in the waste water. When the content reaches 10 mg / l, the waste water is lifted into the ammonia nitrogen treatment device with a steam-water mixing pump, and then the separation device is started. The ammonia nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com