Grinding device

A technology for grinding and grinding surfaces, which can be used in grinding devices, parts of grinding machine tools, grinding/polishing equipment, etc., and can solve problems such as the end of grinding of plate-shaped workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

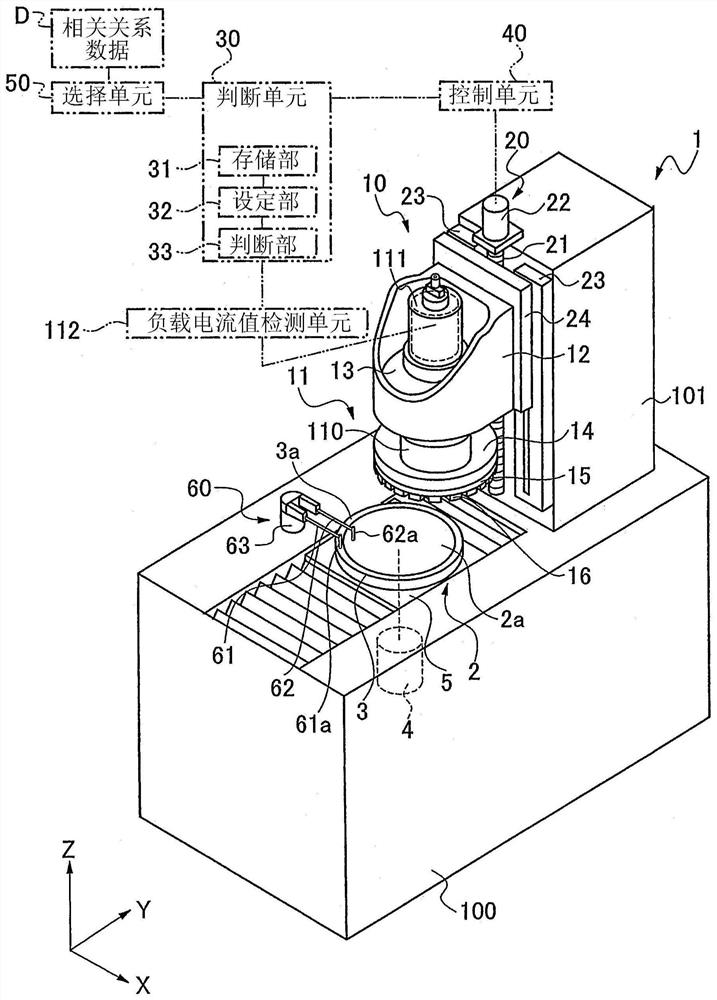

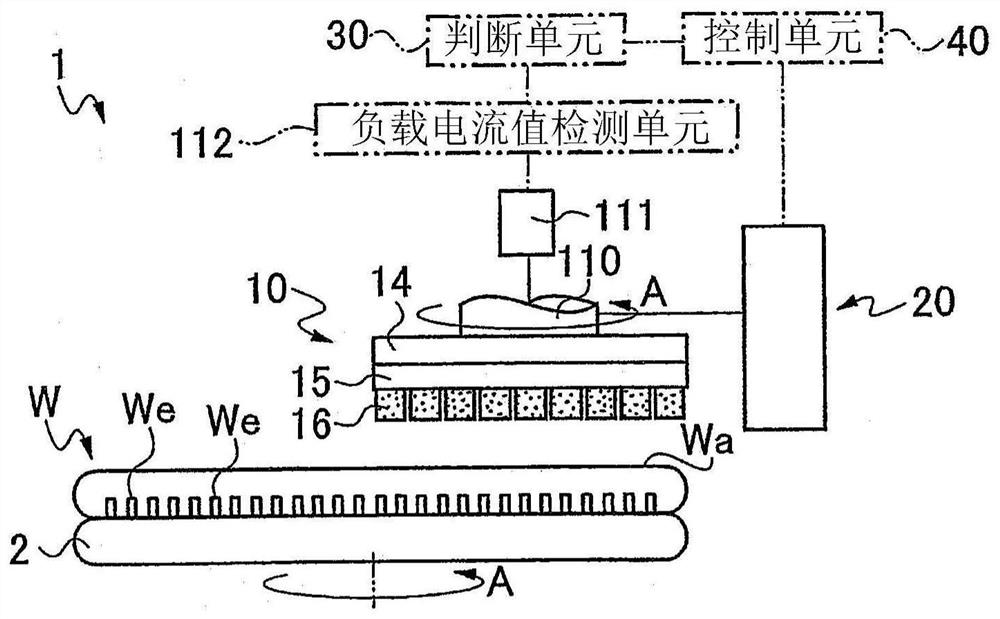

[0023] figure 1 The shown grinding device 1 is an example of a grinding device capable of grinding a plate-shaped workpiece having a plurality of electrodes inside. The grinding apparatus 1 has: an apparatus base 100 extending in the Y-axis direction; and a column 101 erected on the rear side of the apparatus base 100 in the Y-axis direction. On the device base 100, there are a holding table 2 having a holding surface 2a for holding a plate-shaped workpiece having a plurality of electrodes inside, and a holding table rotation unit 4, which rotates. The unit 4 rotates the holding table 2 about the center of the holding table 2 as an axis. The surrounding of the holding surface 2a of the holding table 2 is surrounded by the frame body 3, and the upper surface of the frame body 3 becomes a reference surface 3a having the same height as the holding surface 2a. The periphery of the holding table 2 is covered with a cover 5 and is movable in the Y-axis direction by a movement unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com