A paint spray gun fixing device used in harsh working conditions

A technology of fixing device and spraying gun, applied in the direction of spraying device, etc., can solve the problems of affecting work efficiency, large freedom of movement, limited application occasions, etc., and achieve the effect of flexible adjustment, reduction of operation force, and protection of physical and mental health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

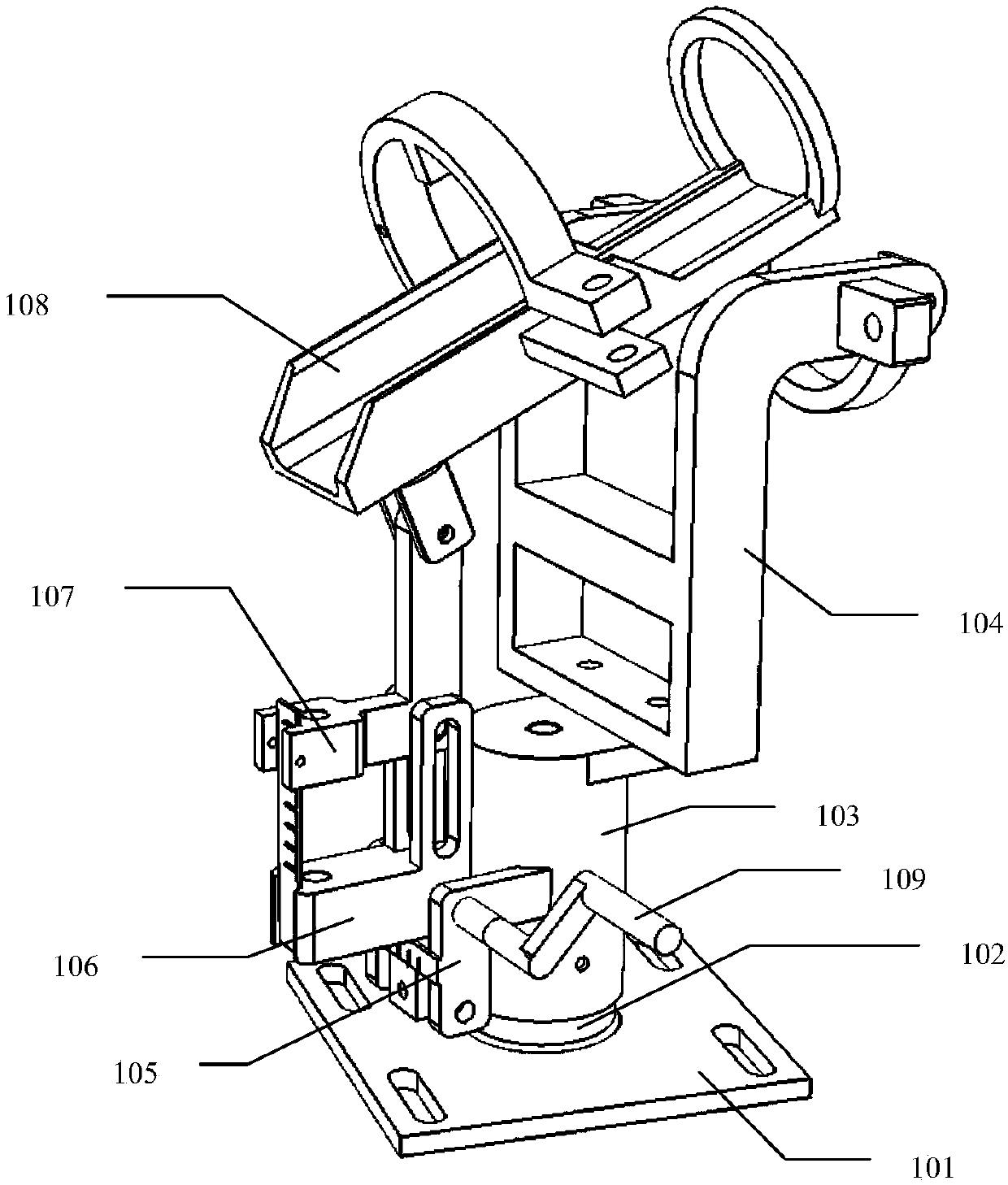

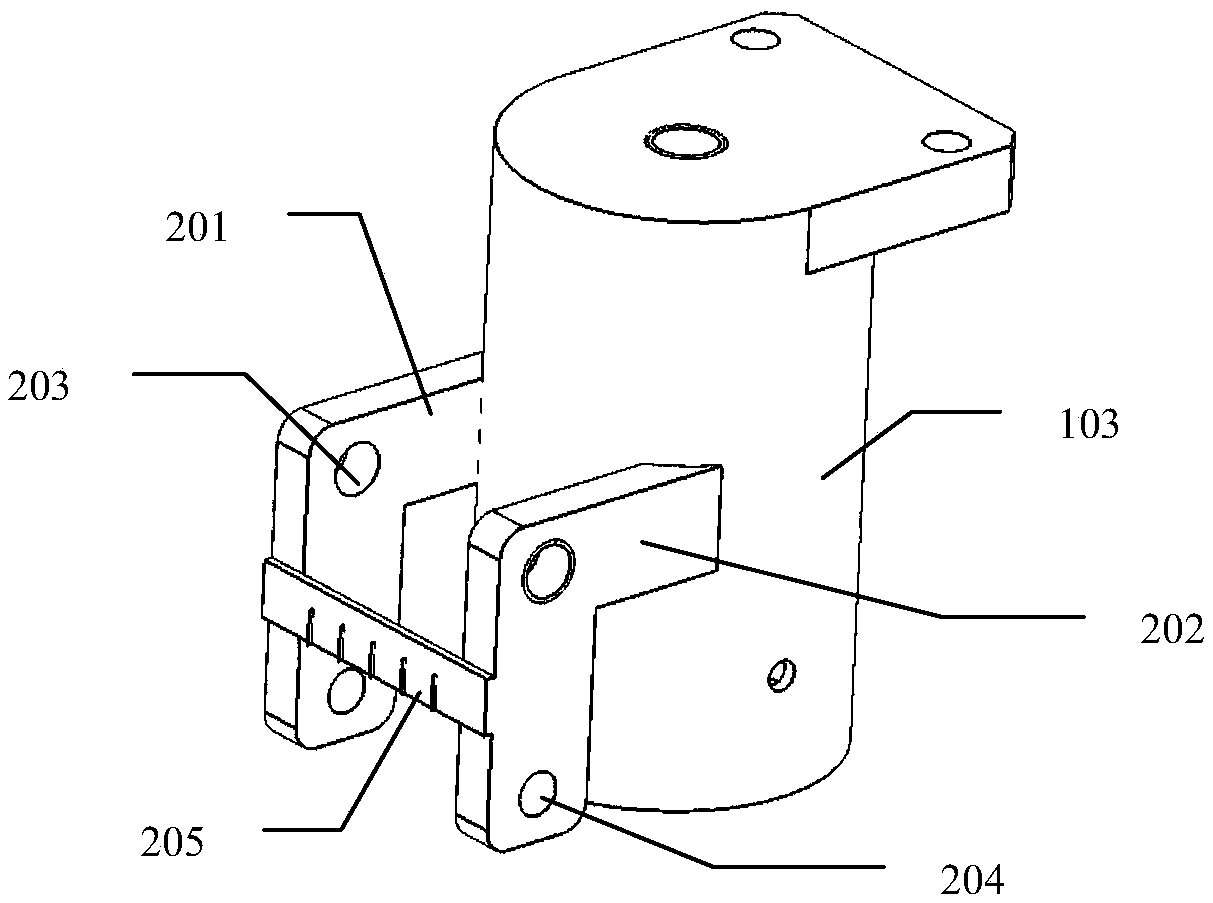

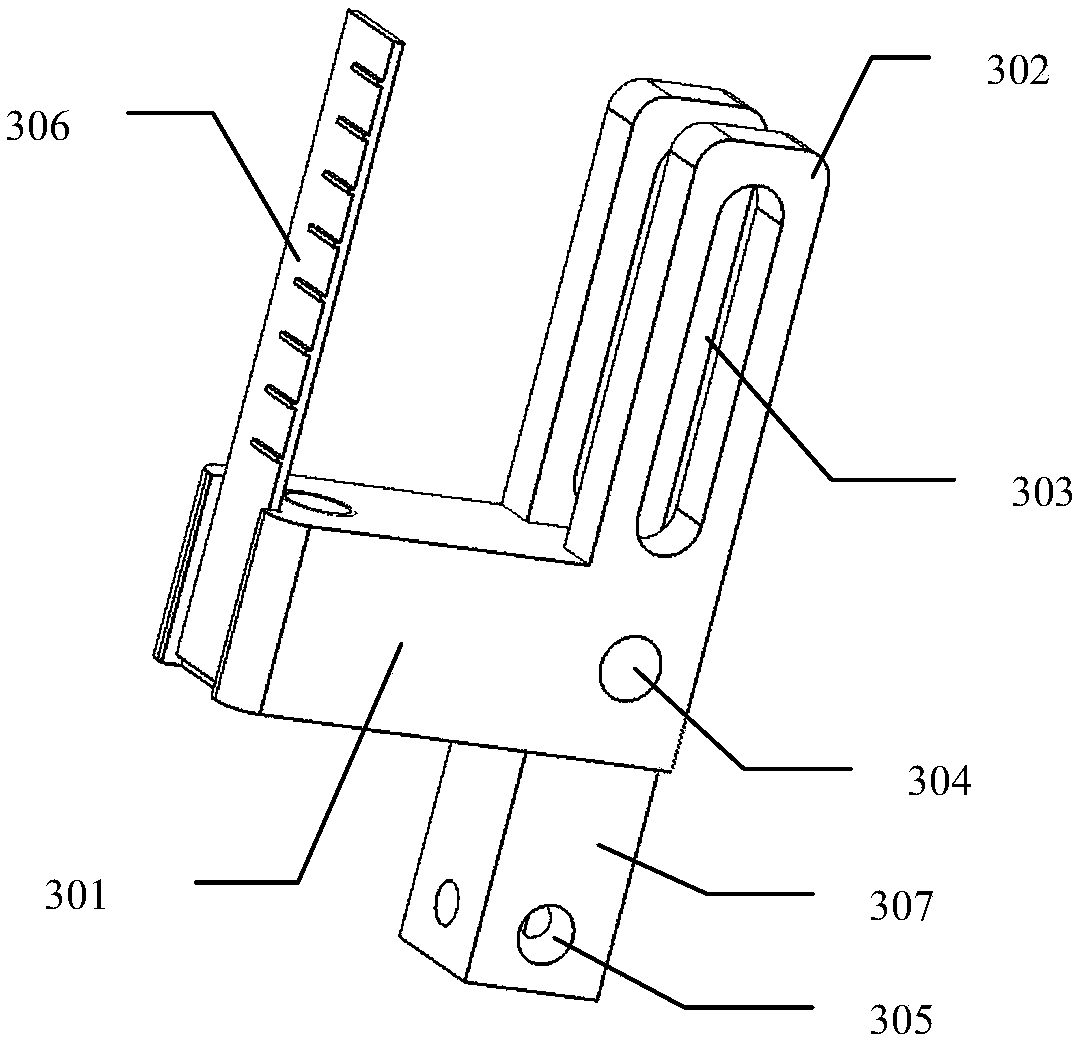

[0024] refer to Figure 1 to Figure 6 , the preferred embodiment 1 of the present invention provides a paint spray gun fixing device under harsh working conditions, including a base 101, a lifting mechanism and a mounting seat 108, and also includes a first adjustment frame 106 and a second adjustment frame 107, and the lifting mechanism consists of The lifting device 102 arranged on the base 101 and the cylinder 103 on the outer peripheral side of the lifting device are composed. The cylinder 103 can rotate freely with the lifting device 102 as the axis; the top right side of the cylinder is provided with a support arm 104; The left lateral wall is provided with a fixed mount, which is composed of mutually symmetrical front fixed mounts 202 and rear fixed mounts 201. The tops of the front fixed mounts 202 and the rear fixed mounts 201 are respectively provided with mutually corresponding jacks 203, and the front fixed mounts 202 and the rear fixed mounts 201 are respectively p...

Embodiment 2

[0032]refer to Figure 7 , the preferred embodiment 2 of the present invention provides a paint spray gun fixing device under severe working conditions. The difference from embodiment 1 is that the lifting device described in embodiment 1 is set as a first electric telescopic rod, and the barrel The top end of the electric telescopic rod is connected through an axially fixed rolling bearing.

[0033] A second electric telescopic rod 703 is provided between the first horizontal fixed rod and the second horizontal fixed rod.

[0034] Described rocking bar is replaced by micromotor 702, and described base is provided with controller 701, and described first electric telescopic link (lifting device 102), second electric telescopic link 703 and micromotor 702 are connected with described controller 701 respectively. connected, the controller is connected wirelessly to a remote control.

[0035] When using the product of this embodiment, select the corresponding adjustment block a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com