Self-assembled collagen and its preparation method

A collagen self-assembly technology, applied in the field of protein engineering, can solve the complex self-assembly process of collagen, and the preparation method of collagen samples needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The self-assembled collagen was prepared to prepare self-assembled cattle type I collagen as an example.

[0034] Self-assembled collagen is prepared in a 5 mg / ml bull type I collagen aqueous solution.

[0035] (1) The collagen concentration is added to the E / S for 8000 u / g to add trypsin, and then the pH is adjusted with 0.1 mol / l NaOH during hydrolysis, and the reaction system is maintained at 8.0, boiling water bath. The enzyme was killed for 20 min, and then papain was added to 50 ° C for 3 hours, and the pH was adjusted with 0.1 mol / L NaOH during hydrolysis to allow the reaction system pH to maintain 7.0. Bulse the hydraulic enzyme for 20 min, cool. Finally, 5000 g / min centrifuge 10min, discard the precipitate, and collected the supernatant.

[0036] (2) The hydrolyzate obtained by step (1) is ultrafined with an ultrafiltration membrane of 1 kDa to obtain a collagen polypeptide solution, and is placed in a refrigerator at 4 ° C.

[0037](3) The collagen pol...

Embodiment 2

[0041] Example 2 An electrophoresis analysis of obtained collagen polypeptides and self-assembled collagen polypeptides

[0042] The collagen polypeptide solution obtained in Example 1 was electrophoresed by electrophoresis with the self-contained collagen polypeptide solution, as follows:

[0043] SDS-PAGE gel electrophoresis analysis

[0044] The self-assembly polypeptide obtained before and after the SDS-PAGE gel electrophoresis was identified using 5% concentrated glue concentration, 20% and 12% separation glue concentration.

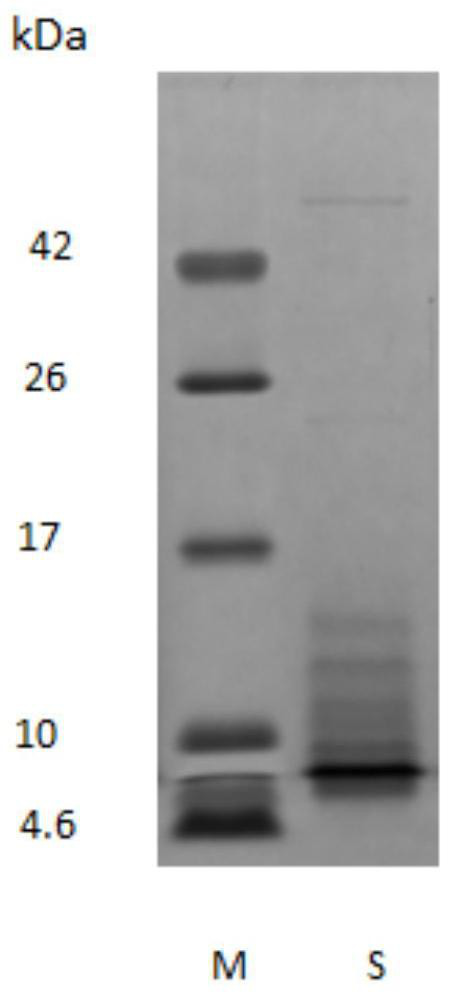

[0045] Such as Figure 1A As shown, the collagen is compared to the standard protein Maker, and it can be seen that the molecular weight of the hydrolysis is small, mostly concentrated below 10 kDa, and the schematic is a cow type I collagen after protease hydrolysis in Example 1. Polypeptide.

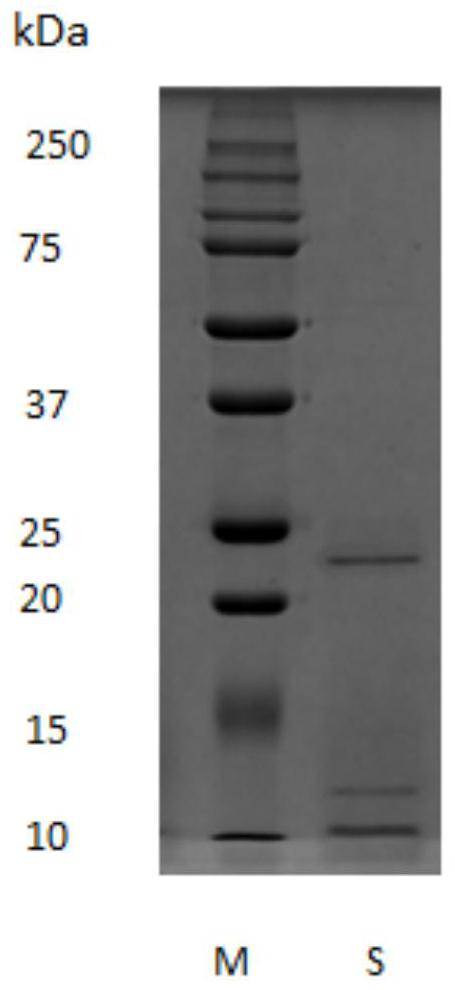

[0046] Such as Figure 1B As shown, the collagen polypeptide is self-assembled, the molecular weight is significantly large, mainly concentrated 22.5 kDa, 10 kDa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com