Polishing liquid and preparation method thereof

A polishing liquid and abrasive technology, applied in polishing compositions containing abrasives, etc., can solve the problems of low polishing efficiency, poor glass surface quality, poor suspension and dispersibility of polishing liquid, etc., and achieve high polishing efficiency, excellent performance, Enhance the effect of close contact and interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The second aspect of the present invention relates to a preparation method of the polishing liquid of the present invention, the method comprising: first dissolving the abrasive and the dispersant in water, stirring uniformly, adding an oxidizing agent, and stirring uniformly, adding a pH regulator.

[0019] The third aspect of the present invention relates to a glass polishing method, which includes polishing glass with the polishing liquid described in the present invention.

Embodiment 1-7

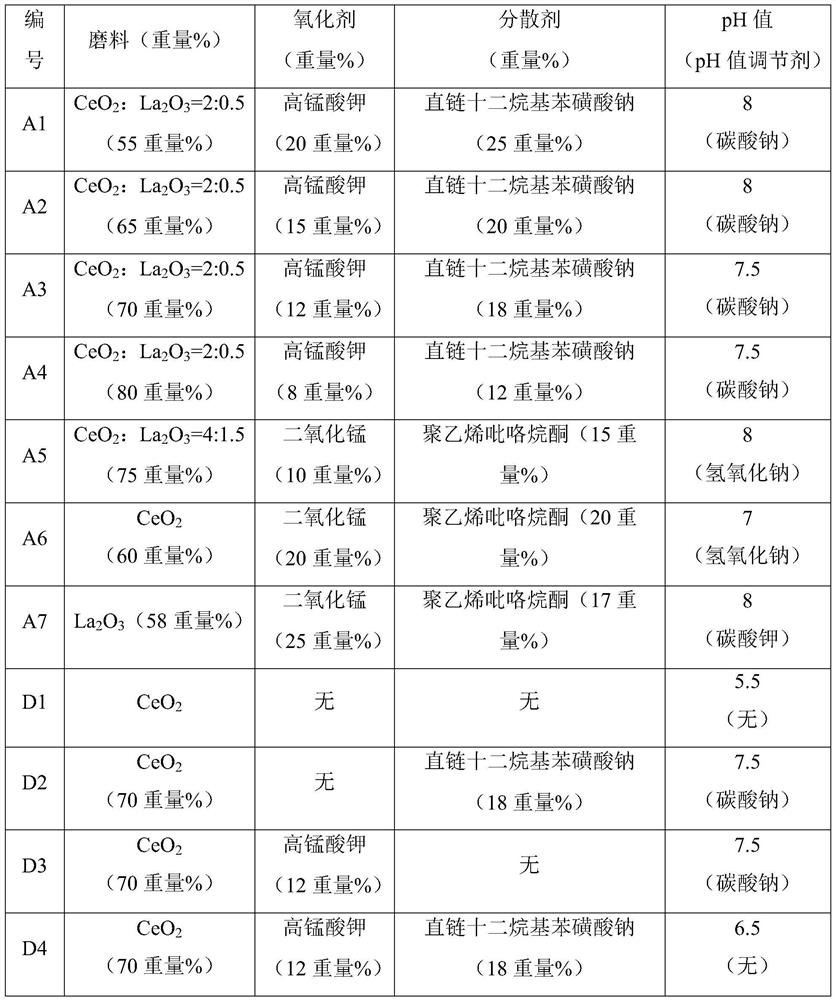

[0022] Weigh the abrasive, dispersant and oxidant according to the content of each component in the polishing liquid. Dissolve the abrasive and dispersant in an appropriate amount of water, and perform mechanical stirring. After the dispersion is uniform, continue to add an oxidant and perform mechanical stirring. Then, add an appropriate amount of pH regulator to adjust the pH value of the polishing solution to 7-8. Obtain the alkaline polishing liquid A1-A6.

Embodiment 12-18 and comparative example 19-22

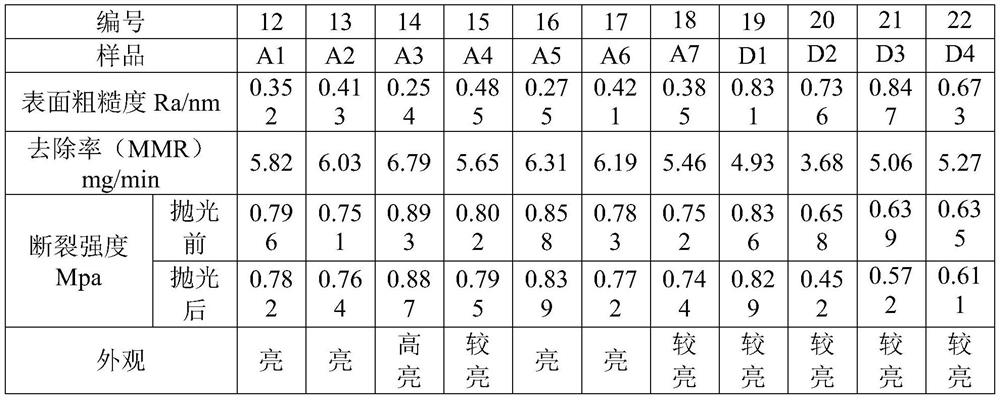

[0028] The same glasses were polished using polishing solutions A1-A7 and D1-D4 respectively, and then the following tests were performed, and the results are shown in Table 2.

[0029] Removal rate: After polishing and cleaning the glass, detect the glass surface quality and polishing rate, measure the quality difference before and after polishing with a precision balance, and calculate the removal rate.

[0030] Surface roughness: use a surface roughness tester to detect the surface roughness of the polished glass.

[0031] According to ASTM E-1820, use a universal testing machine and a Vickers hardness tester to measure glass fracture toughness K IC .

[0032] Table 2

[0033]

[0034] It can be seen from the results in Table 1 that after the glass is polished with the polishing liquid according to the present invention, the glass surface has low roughness, high removal rate and smooth glass surface. Moreover, the polishing liquid of the present invention enhances the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com