Method for preparing yolk-shell structure Co9Se8 nano-particles

A nanoparticle and shell structure technology, applied in nanotechnology, nanotechnology, structural parts, etc., can solve the problems of no yolk-shell structure nanoparticles, etc., and achieve good application prospects, process controllability, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

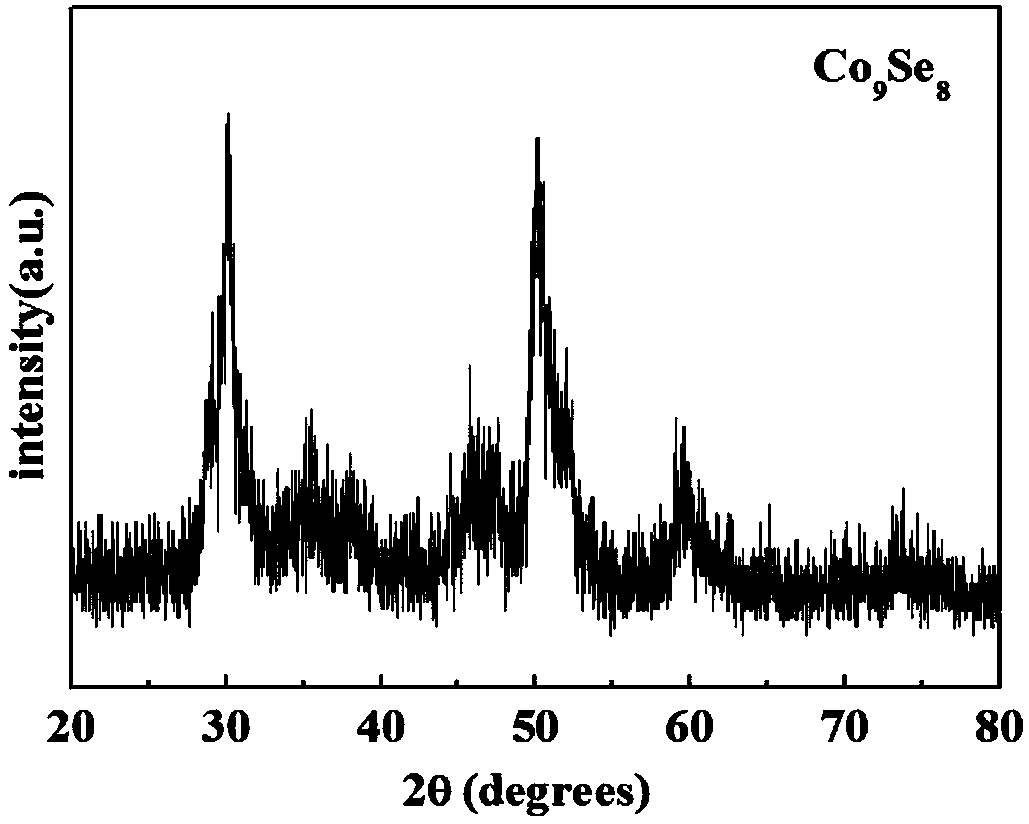

Image

Examples

Embodiment 1

[0020] Weigh Co(NO 3 ) 2 ·6H 2 O powder 0.1g, glycerol 8ml were dissolved in 40ml isopropanol to form a mixed solution. Stir the prepared solution ultrasonically for 20 minutes, transfer the mixed solution after stirring to a polytetrafluoroethylene reactor for hydrothermal treatment, keep the hydrothermal temperature at 180 ° C, and keep the hydrothermal time at 6 hours. After the reaction is completed, the powder Centrifugal cleaning was carried out to obtain a Co spherical precursor. Take 40mg of Co spherical precursor and 20ml of deionized water to make a mixed solution, add 10mg of selenous acid and 10ml of hydrazine hydrate solution in turn, stir for 2min, transfer the mixed solution to the reactor for hydrothermal treatment, and keep the hydrothermal temperature at 180 ℃, the hydrothermal time is kept at 24h, and the powder after the reaction is centrifuged to clean, and finally the egg yolk-shell structure Co 9 Se 8 nanoparticles.

Embodiment 2

[0022] Weigh Co(NO 3 ) 2 ·6H 2 O powder 0.2g, glycerol 16ml were dissolved in 80ml isopropanol to form a mixed solution. Stir the prepared solution ultrasonically for 20 minutes, transfer the mixed solution after stirring to a polytetrafluoroethylene reactor for hydrothermal treatment, keep the hydrothermal temperature at 180°C, and keep the hydrothermal time at 8h. After the reaction is completed, the powder Centrifugal cleaning was carried out to obtain a Co spherical precursor. Take 30mg of Co spherical precursor and 15ml of deionized water to make a mixed solution, add 10mg of selenous acid and 10ml of hydrazine hydrate solution in turn, stir for 2min, transfer the mixed solution to the reactor for hydrothermal treatment, and keep the hydrothermal temperature at 180 ℃, the hydrothermal time is kept at 24h, and the powder after the reaction is centrifuged to clean, and finally the egg yolk-shell structure Co 9 Se 8 nanoparticles.

Embodiment 3

[0024] Weigh Co(NO 3 ) 2 ·6H 2 O powder 0.1g, glycerol 8ml were dissolved in 40ml isopropanol to form a mixed solution. Stir the prepared solution ultrasonically for 20 minutes, transfer the mixed solution after stirring to a polytetrafluoroethylene reactor for hydrothermal treatment, keep the hydrothermal temperature at 180 ° C, and keep the hydrothermal time at 6 hours. After the reaction is completed, the powder Centrifugal cleaning was carried out to obtain a Co spherical precursor. Take 40mg of Co spherical precursor and 20ml of deionized water to make a mixed solution, add 20mg of selenous acid and 20ml of hydrazine hydrate solution in turn, stir for 2min, transfer the mixed solution to the reactor for hydrothermal treatment, and keep the hydrothermal temperature at 200 ℃, the hydrothermal time is kept at 24h, and the powder after the reaction is centrifuged to clean, and finally the egg yolk-shell structure Co 9 Se 8 nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com