Hydrophobic starch and preparation method thereof

A technology for hydrophobic starch and starch, applied in the field of hydrophobic starch and its preparation, can solve the problems of inability to preserve starch granule structure, large environmental pollution, low reaction efficiency, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing hydrophobic starch by in-situ solid phase grafting of the present invention comprises the following steps:

[0026] (1) Disperse 0.02 parts by weight of zinc lactate in 2 parts by weight of lactic acid monomer to obtain a dispersion liquid, mix the dispersion liquid with 20 parts by weight of starch, and stir evenly to obtain a mixture.

[0027] (2) Put the mixture in a hydrothermal reaction kettle, seal it and place it for 1 hour, so that the dispersion liquid can fully penetrate into the starch.

[0028] (3) React at 100°C for 3h to obtain lactic acid grafted starch.

[0029] (4) The lactic acid grafted starch was washed with acetone to remove the unreacted lactic acid and polylactic acid homopolymer, and then dried in an oven at 50° C. to obtain pure lactic acid grafted starch.

Embodiment 2

[0031] A method for preparing hydrophobic starch by in-situ solid phase grafting of the present invention comprises the following steps:

[0032] (1) Disperse 0.1 parts by weight of azobisisobutyronitrile in 10 parts by weight of methyl methacrylate monomer to obtain a dispersion, mix the dispersion with 20 parts by weight of starch, and stir to obtain a mixture .

[0033] (2) Put the mixture in a hydrothermal reaction kettle, seal it and place it for 6 hours, so that the dispersion liquid can fully penetrate into the starch.

[0034] (3) Reaction at 70° C. for 12 h to obtain methyl methacrylate grafted starch.

[0035] (4) Methyl methacrylate grafted starch is washed with acetone to remove unreacted methyl methacrylate monomer and polymethyl methacrylate homopolymer, and then placed in a 50°C oven to dry to obtain methacrylic acid Pure methyl ester grafted starch.

Embodiment 3

[0037] A method for preparing hydrophobic starch by in-situ solid phase grafting of the present invention comprises the following steps:

[0038] (1) Disperse 0.4 parts by weight of dibenzoyl peroxide in 20 parts by weight of styrene monomer to obtain a dispersion liquid, mix the dispersion liquid with 20 parts by weight of starch, and stir evenly to obtain a mixture.

[0039] (2) Put the mixture in a hydrothermal reaction kettle, seal it and place it for 12 hours, so that the dispersion liquid can fully penetrate into the starch.

[0040] (3) Reaction at 90°C for 8h to obtain styrene-grafted starch.

[0041] (4) Styrene-grafted starch was washed with acetone to remove unreacted styrene monomer and polystyrene homopolymer, and then dried in an oven at 50° C. to obtain pure styrene-grafted starch.

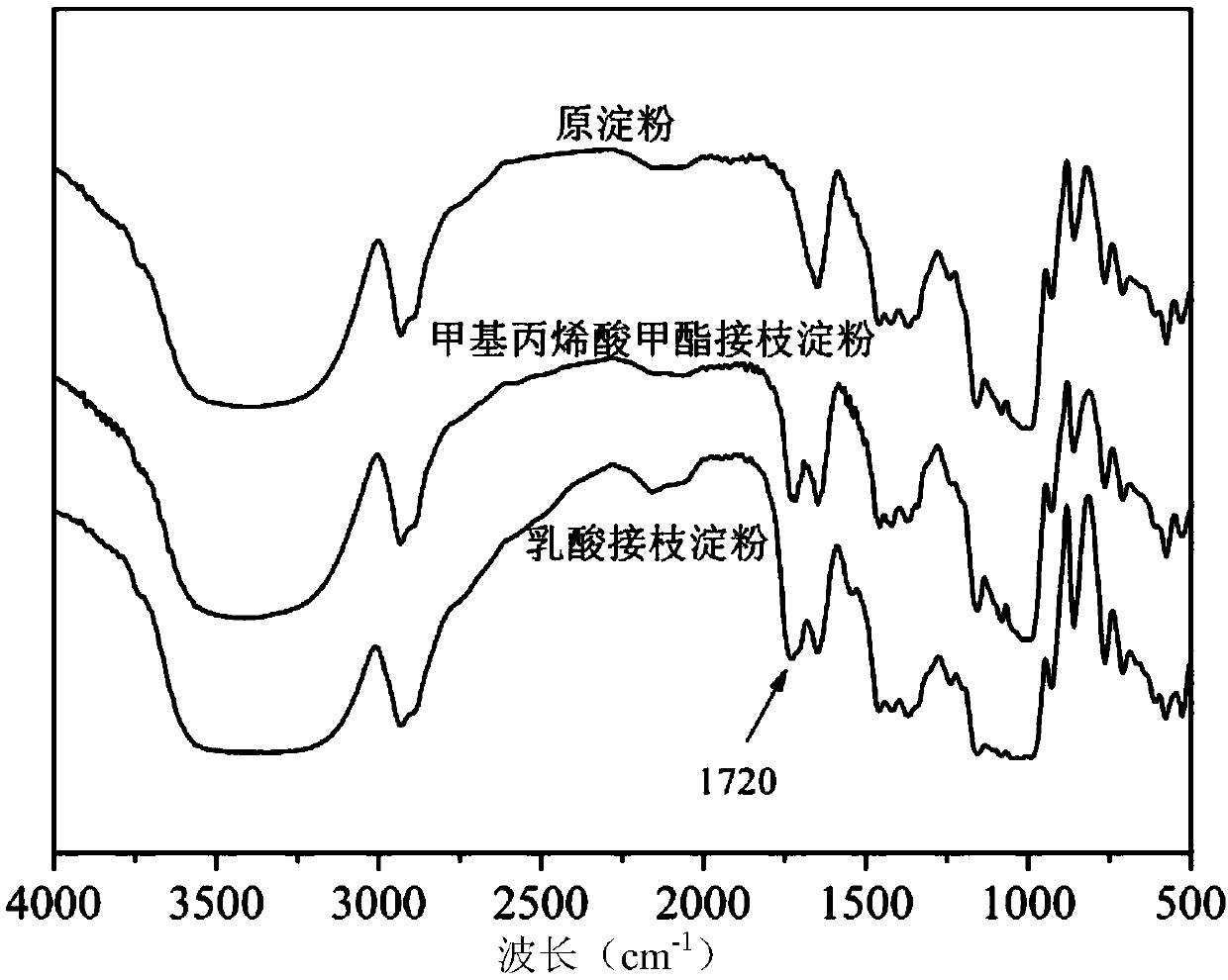

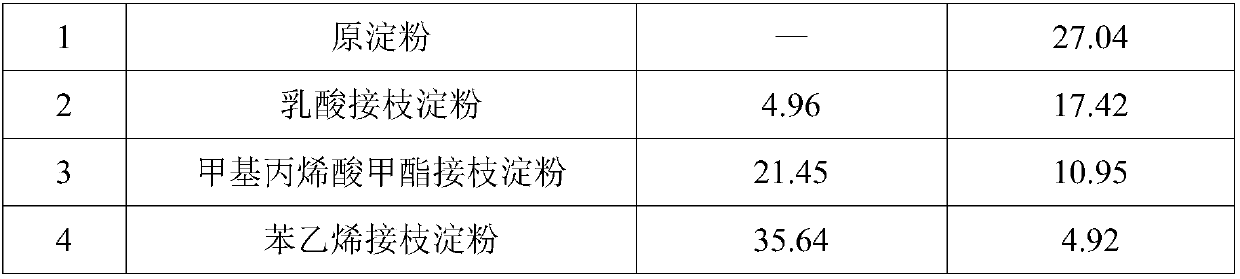

[0042] The original starch, the lactic acid grafted starch of embodiment 1 and the methyl methacrylate grafted starch of embodiment 2 are carried out infrared spectrum detection re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com