Full-automatic reinforcing-steel-bar feeding machine with fixed-length feeding function

A fully automatic, fixed-length technology, applied in the field of fully automatic steel bar feeder, can solve the problems of inaccurate fixed-length feeding, uncontinuous feeding, unreliable clamping, etc., to achieve accurate length, high working stability, and feeding efficiency consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

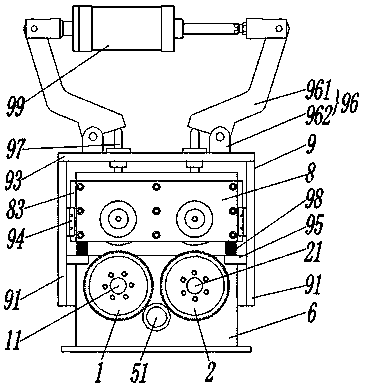

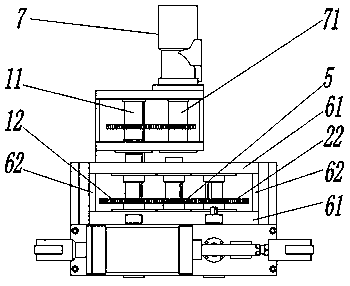

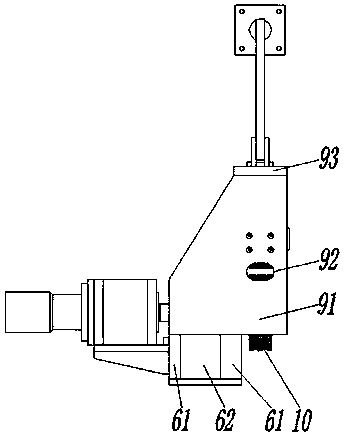

[0052] see Figure 1~6 , a fully automatic steel bar feeder capable of feeding at a fixed length, including a first driven wheel 3 and a first driving wheel 1 arranged up and down on the same vertical plane, and the first driving wheel 1 is arranged on a first rotating shaft 11, so The first rotating shaft 11 is rotatably coupled to the frame body 6, and the first rotating shaft 11 is connected to the hydraulic motor 7 to input torque; it also includes a vertical plane located in the vertical plane where the first driven wheel 3 and the first driving wheel 1 are located and paired up and down. The second driven wheel 4 and the second driving wheel 2 are provided; the second driving wheel 2 is arranged on the second rotating shaft 21 , and the second rotating shaft 21 is rotatably coupled to the frame body 6 .

[0053] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com