A crimping type cable conductor joint with current equalizing function and preparation method thereof

A cable conductor and crimping technology, which is applied in the field of crimping cable conductor joints and preparations, can solve the problems of high temperature rise at the joints and potential safety hazards at the cable conductor joints, and improve the AC resistance and increase the current. The effect of uniform distribution and strong field operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

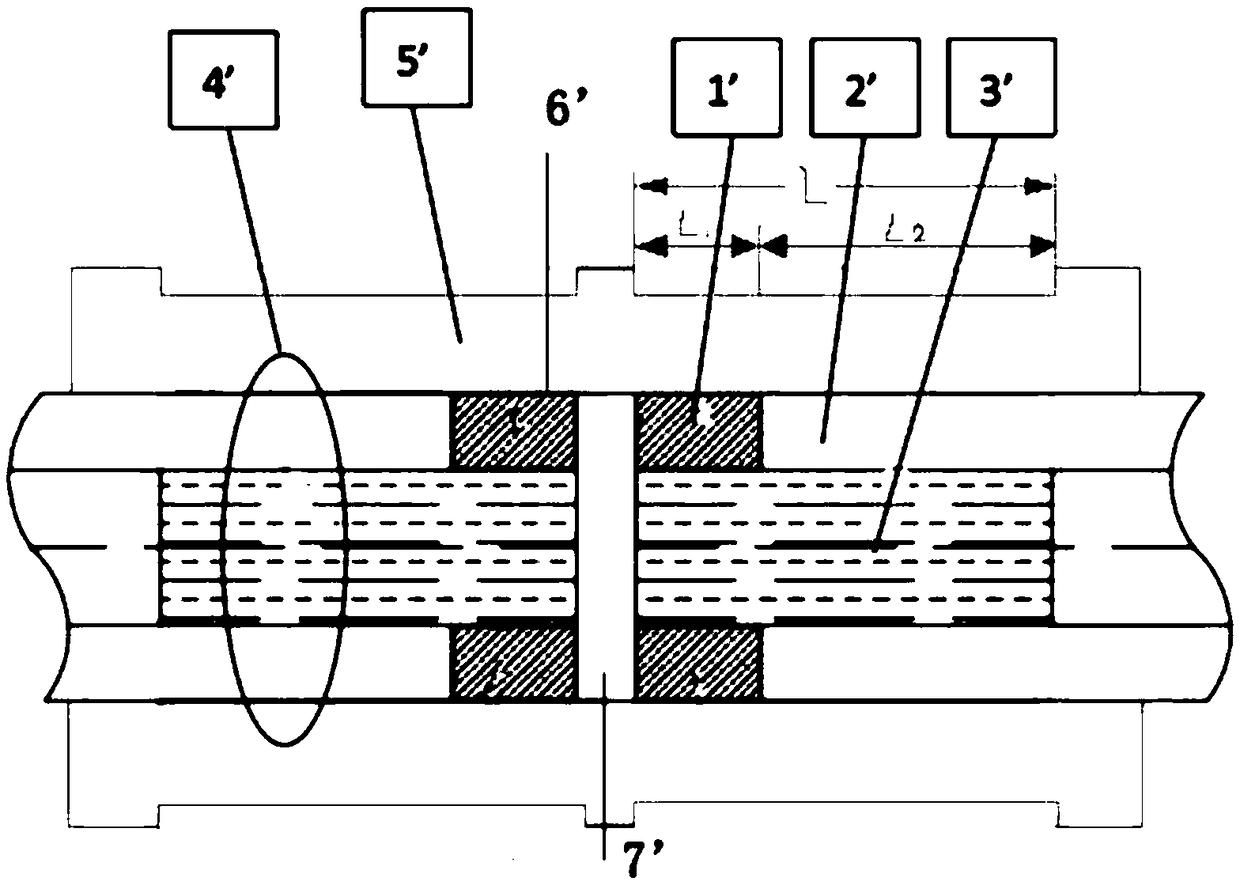

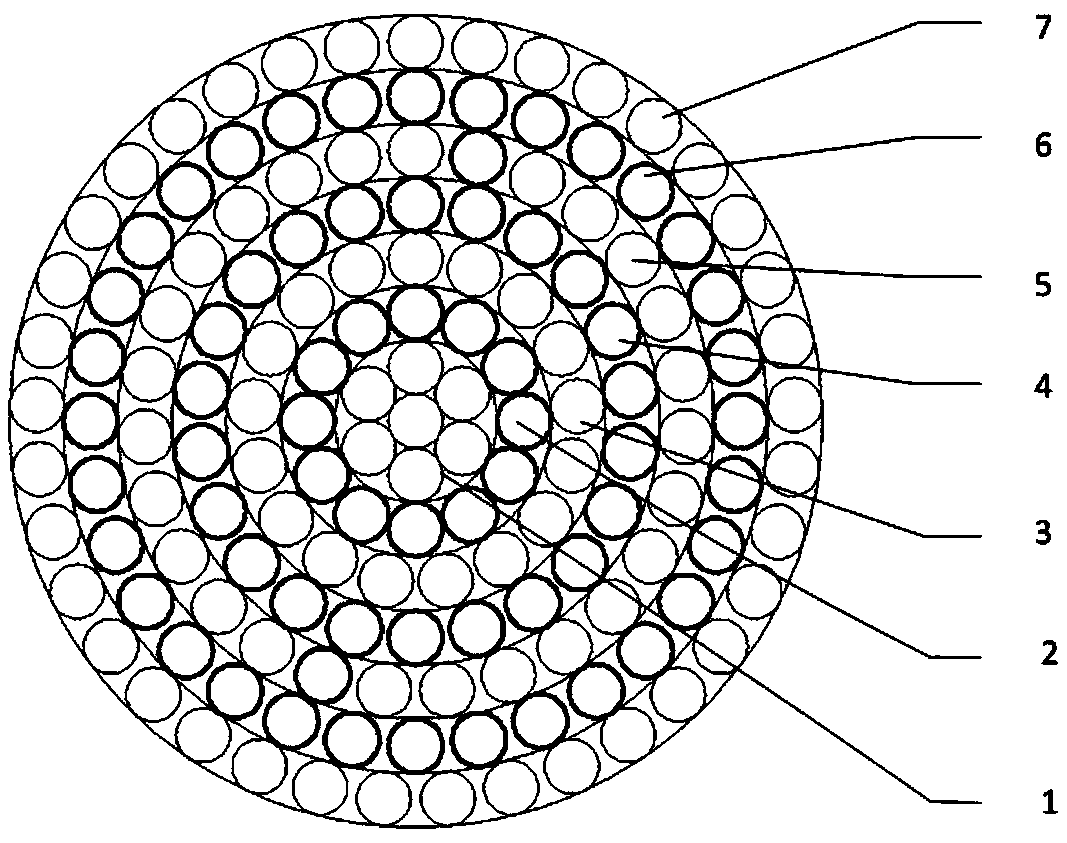

[0058] 1 Assume that the total number of conductor layers is N layers, and the internal welding layer is M layers, where M needs to be an integer. Before welding starts, it is necessary to ensure that the paint film of the crimped section has been removed and each layer has been fastened and fixed. Within the effective distance of crimping, counting from the center conductor to the M layer is defined as the area 3', such as figure 1 As shown in , layers M to N are defined as area 2'. Each layer of conductors in area 3' is brazed with gas flame of length L with welding rod A. After welding, it is ground into a uniform cylinder with a file and an electric sander, and the outer diameter is controlled to be consistent with the outer diameter of the M conductor. The conductors of each layer in the area 1' are carried out with the welding rod B to a length L 1 gas flame brazing.

[0059] according to Figure 4 and Figure 5 , R 1j It is the radial resistance of area 1', which...

Embodiment 2

[0074] 1 Assume that the total number of conductor layers is N layers, and the internal welding layer is M layers, where M needs to be an integer. Before welding starts, it is necessary to ensure that the paint film of the crimping section L has been removed and each layer has been fastened and fixed. Within the effective distance of crimping, counting from the center conductor to the M layer is defined as the area 3', such as figure 1 As shown in , layers M to N are defined as area 2'. Each layer of conductors in area 3' is gas flame brazed with electrode A to length L to fill the gaps and surfaces between the conductors of each layer with electrodes, and after welding, use a file and an electric sander to grind it into a uniform cylinder. The outer diameter of the control is consistent with the outer diameter of the M-layer conductor. The conductors of each layer in the area 1' are carried out with the welding rod B to a length L 1 gas flame brazing. The layers of condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com