A kind of perovskite film layer has micro-crack perovskite battery and the preparation method of the battery

A perovskite cell, perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as inability to efficiently export excitons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

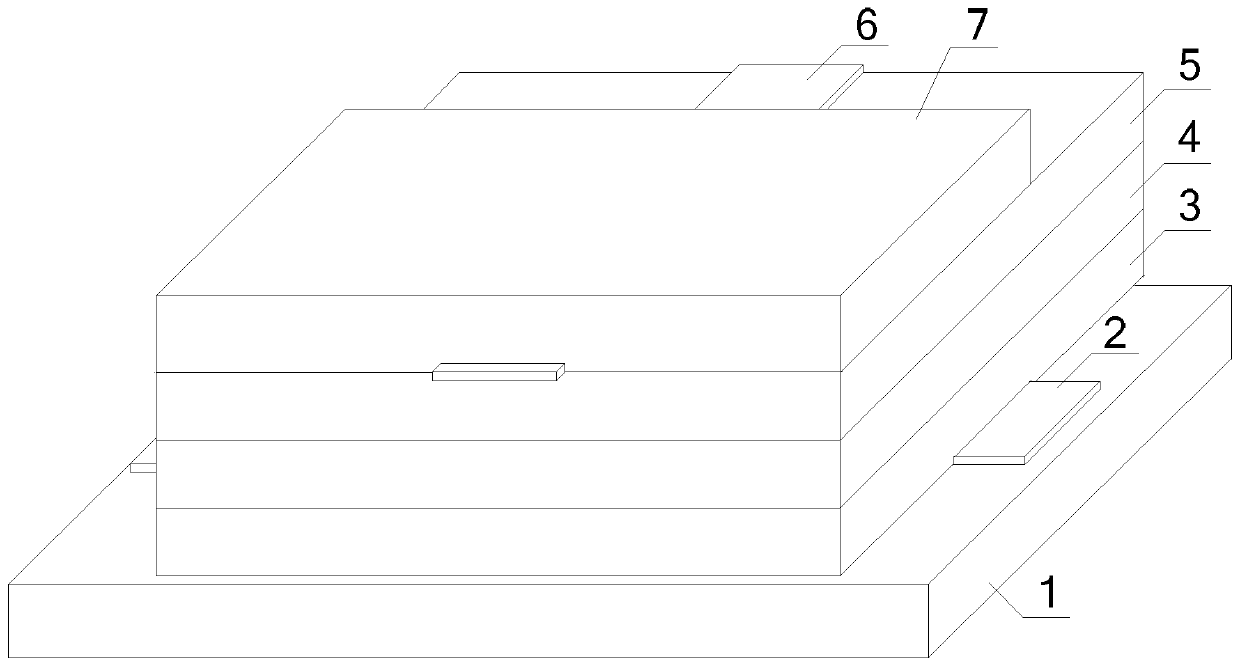

[0018] Specific implementation mode one: refer to figure 1 Describe this embodiment in detail. A perovskite thin film layer described in this embodiment has a perovskite cell with microcracks, including: a first substrate 1, a first electrode 2, a mesoporous layer 3, and a perovskite thin film layer 4, hole transport layer 5, second electrode 6 and second substrate 7;

[0019] The first substrate 1, the first electrode 2, the mesoporous layer 3, the perovskite thin film layer 4, the hole transport layer 5, the second electrode 6 and the second substrate 7 are arranged in order from bottom to top and are in close contact with each other;

[0020] The surface of the perovskite film layer 4 has crack lines.

[0021] A perovskite thin film layer described in this embodiment has a micro-cracked perovskite battery. The innovation of the battery is that the surface of the perovskite thin film layer 4 has crack lines, and these cracks do not penetrate the entire crystal film. This r...

specific Embodiment approach 2

[0022] Specific embodiment 2: This embodiment is a further description of a perovskite thin film layer with a micro-crack type perovskite battery described in specific embodiment 1. In this embodiment,

[0023] Both the first substrate 1 and the second substrate 7 are glass substrates;

[0024] The first electrode 2 is FTO (fluorine-doped SnO 2 transparent conductive glass) electrode, the second electrode 6 is a silver electrode, the thickness is 100nm~200nm;

[0025] The material of the mesoporous layer 3 is TiO 2 , the thickness is 300nm~600nm;

[0026] The material of the perovskite layer 4 is CH 3 NH 3 PB 3 , the thickness is 400nm~1000nm;

[0027] The material of the hole transport layer 5 is Spiro-OMeTAD (2,2',7,7'-tetrakis[N,N-bis(4-methoxyphenyl)amino]-9,9'-spirobifluorene) , with a thickness of 200nm.

specific Embodiment approach 3

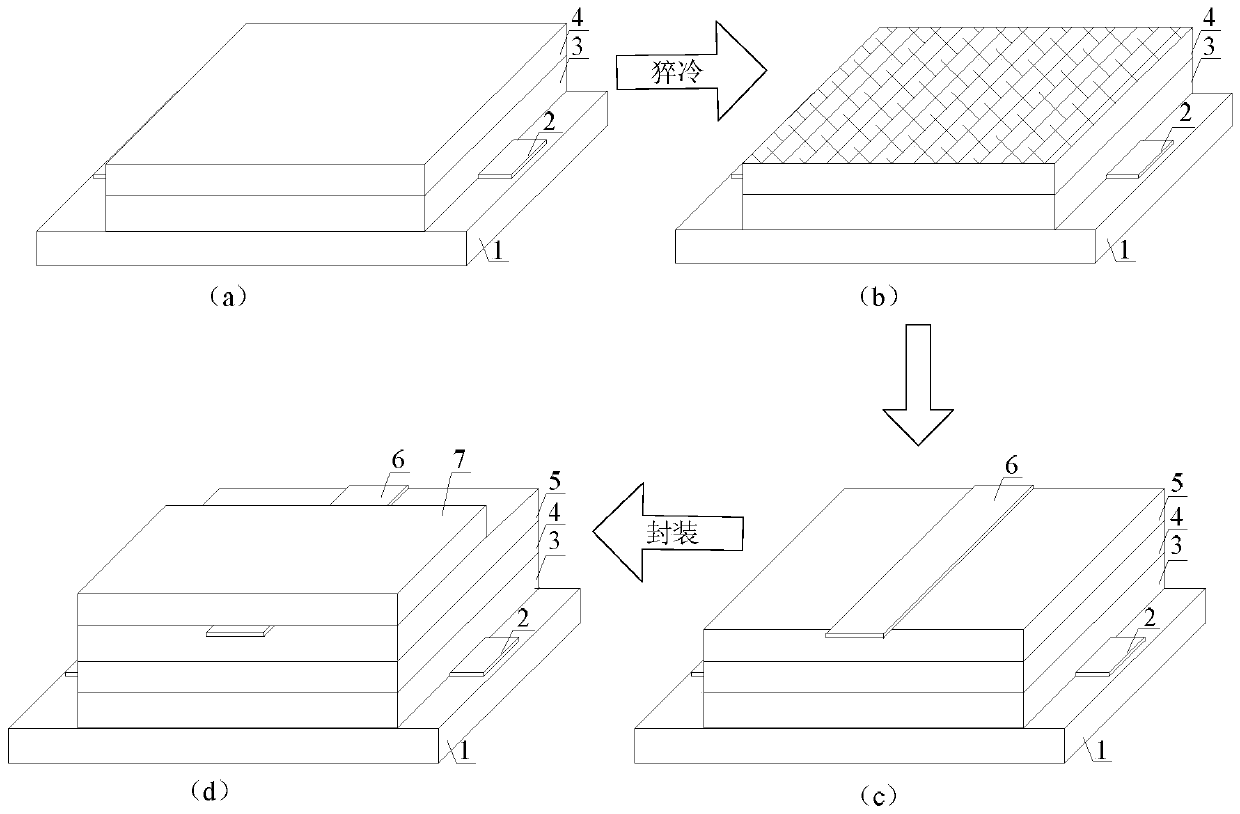

[0028] Specific implementation mode three: refer to figure 2 Specifically illustrate this embodiment, a kind of perovskite film layer described in this embodiment has the method for making the perovskite battery of microcrack type, and this method comprises the following steps:

[0029] Step 1: Spin-coat the mesoporous material on the upper surface of the first substrate 1 covered with the first electrode 2 at a speed of 3000 r / min for 30 seconds to form a mesoporous layer 3;

[0030] Step 2: Spin-coat an alkaline solution of methylamine MAPbI3 perovskite material on the upper surface of the mesoporous layer 3 at a speed of 4500 r / min for 60 seconds to form a perovskite layer 4 and obtain a battery semi-finished product with a perovskite layer 4 on the surface;

[0031] Step 3: thermally annealing the semi-finished battery at 100°C for 10 minutes, and then quenching the semi-finished battery to form cracks on the surface of the perovskite layer 4;

[0032] Step 4: Spin-coat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com