Method for optimally designing non-probabilistic reliability shapes of trusses

A technology for optimizing design and reliability, applied in computing, special data processing applications, instruments, etc., can solve problems affecting the efficiency of structural optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

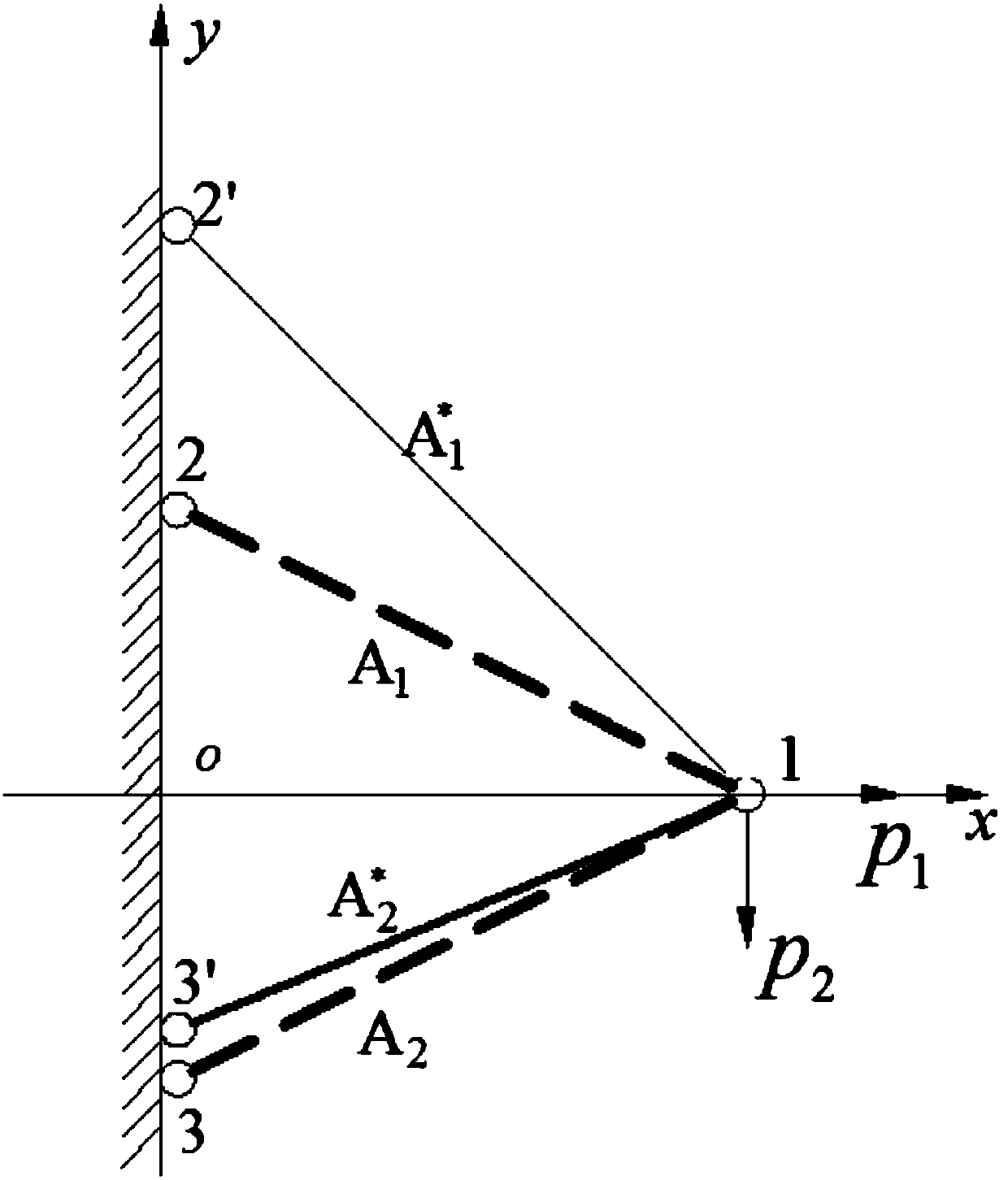

[0047] Such as figure 1 As shown, a kind of truss non-probabilistic reliability shape optimization design method of the present invention comprises the following steps:

[0048] Step 1. Determine the design variables of the truss to be optimized: the truss to be optimized is a space truss composed of multiple straight bars, each of which is called a bar, and the connecting ends of the bars are called nodes. The nodes include fixed nodes and free nodes, and a three-dimensional Cartesian coordinate system is established with any node in the truss to be optimized as the coordinate origin;

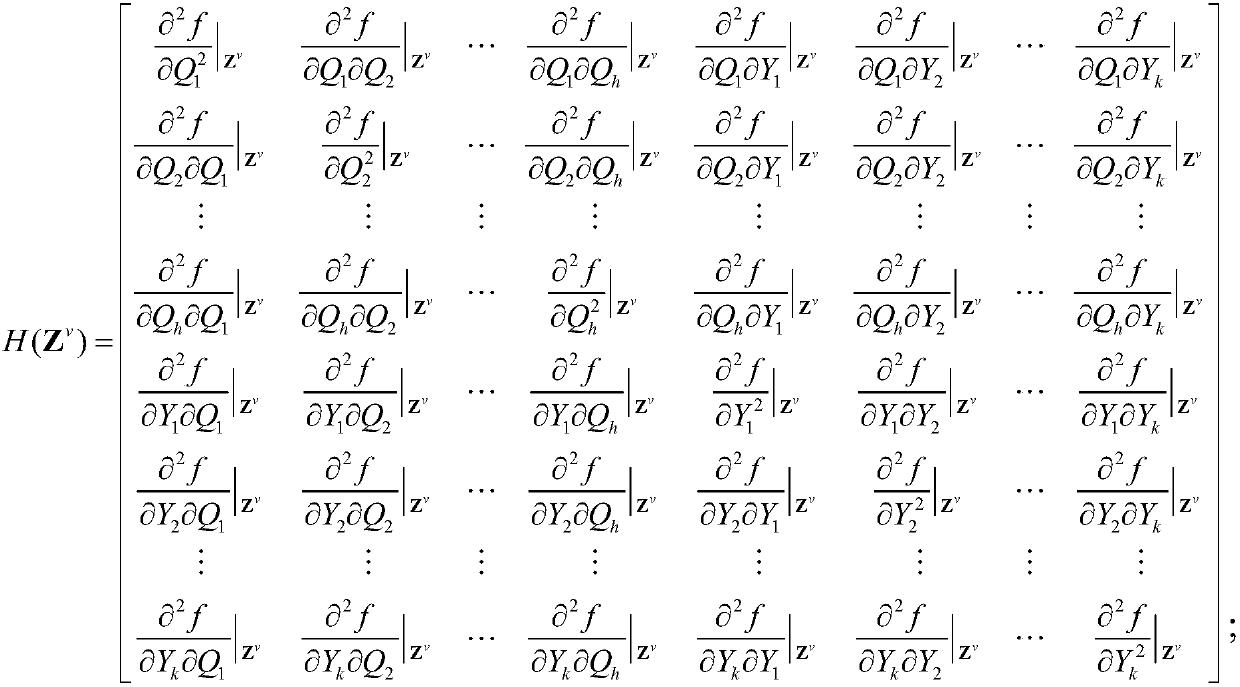

[0049] The cross-sectional area A of the bar to be optimized in the truss to be optimized and the coordinate X of the node to be optimized in the truss to be optimized are used as design variables, wherein the cross-sectional area A of the bar to be optimized=(A 1 ,...,A k )T , k is the number of the member to be optimized and k is a positive integer not less than 2, and the cross-sectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com