Integral ventilated drying device for fodder manufacturing

A feed processing and drying device technology, which is applied in the direction of drying gas arrangement, drying solid materials, drying, etc., can solve the problems of affecting feed processing and consumption, reduced drying effect, and high dust content, so as to avoid incomplete drying and reduce The effect of dust and feeding uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

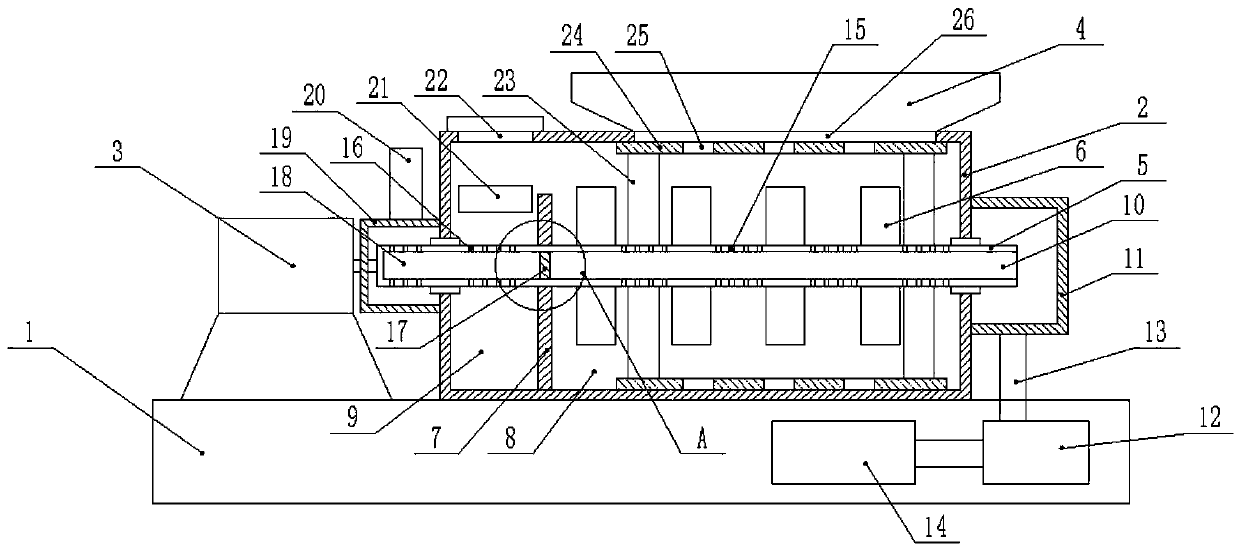

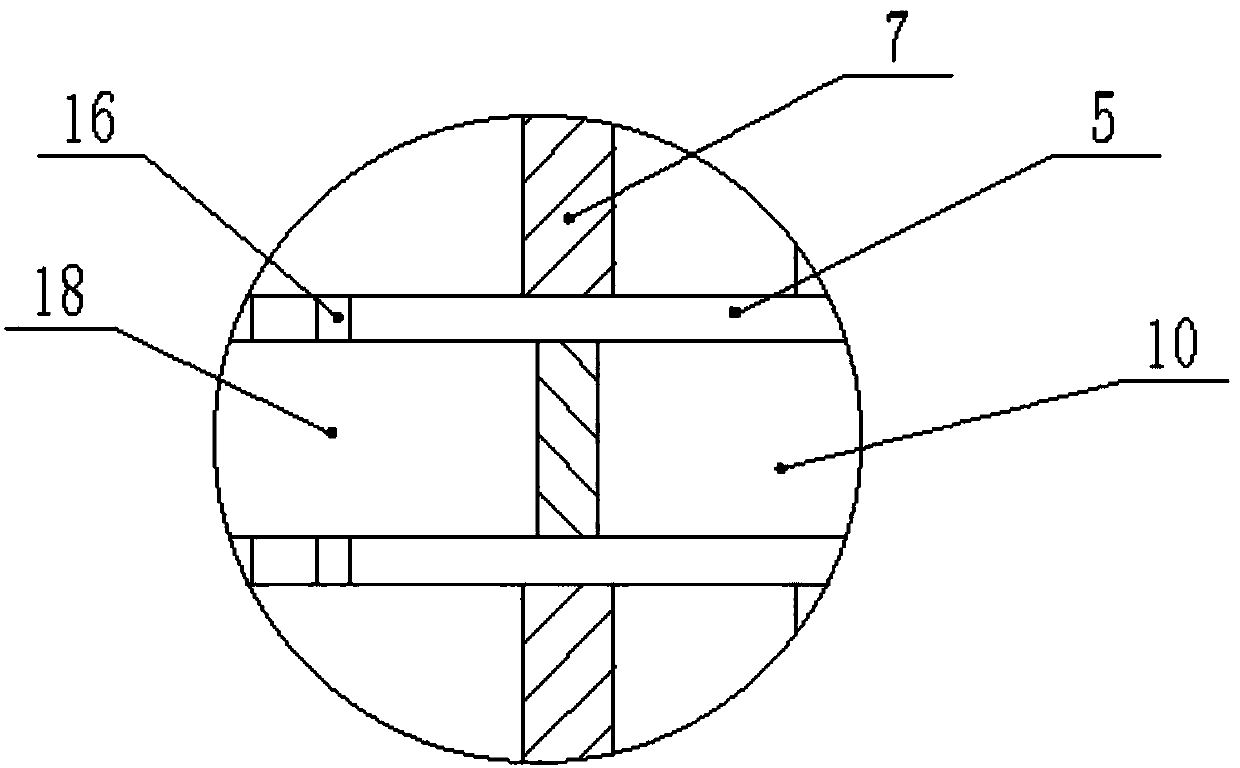

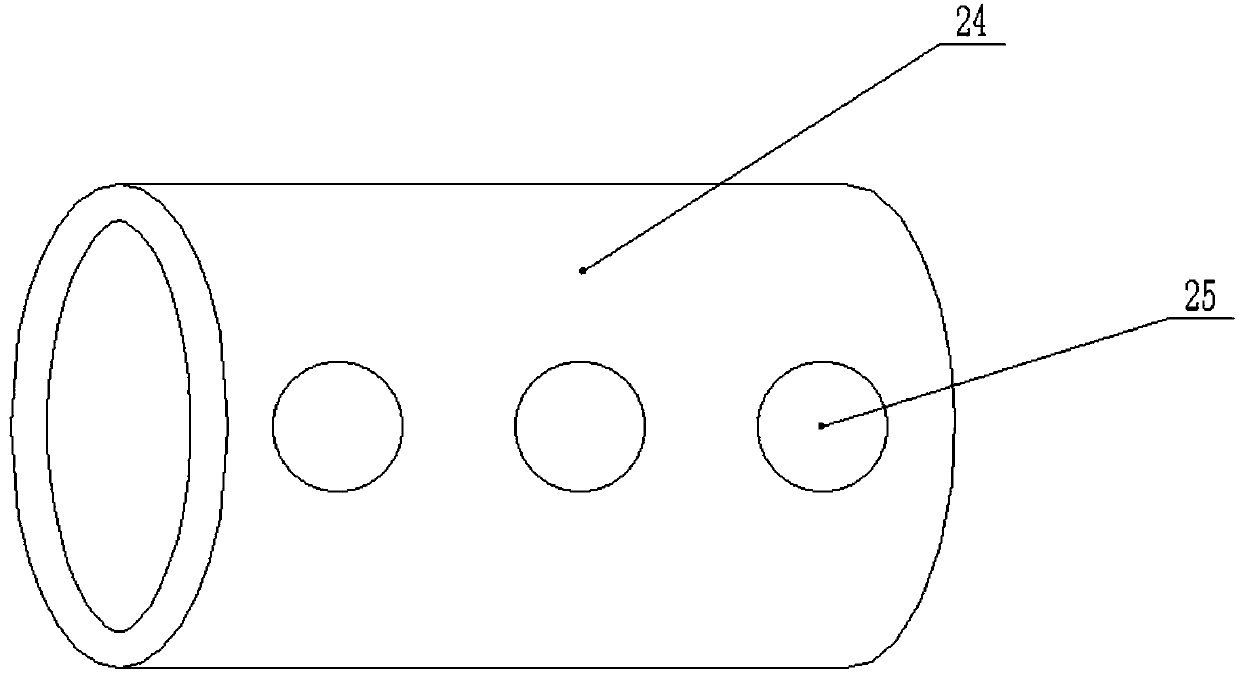

[0019] Please refer to the figure, in the embodiment of the present invention, an integrated ventilated drying device for feed processing includes a base 1, a housing 2, a motor 3 and a feed hopper 4; the housing 2 and the motor 3 are fixedly installed on the base 1, the feed hopper 4 is connected to the top of the housing 2, and a hollow shaft 5 is horizontally pierced in the housing 2. The hollow shaft 5 is connected to the housing 2 through bearings, and the left end of the hollow shaft 5 is sleeved on the outside An exhaust box 19 is provided, and the output shaft of the motor 3 extends horizontally into the base exhaust box 19. The output shaft of the motor 3 is coaxially fixedly connected to the hollow shaft 5, driven by the motor 3 to rotate 5, and the exhaust box 19 Connected with an exhaust pipe 20, the air blown out of the hollow shaft 5 is discharged; the outside of the right end of the hollow shaft 5 is provided with an air inlet box 11, and the hollow shaft 5 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com