Hydraulic system of crane

A hydraulic system and crane technology, applied in cranes, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of increasing the leakage of the hydraulic system, reducing the speed of lifting operations, and failure of the sealing ring, so as to increase the leakage amount and avoid serious effects of resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

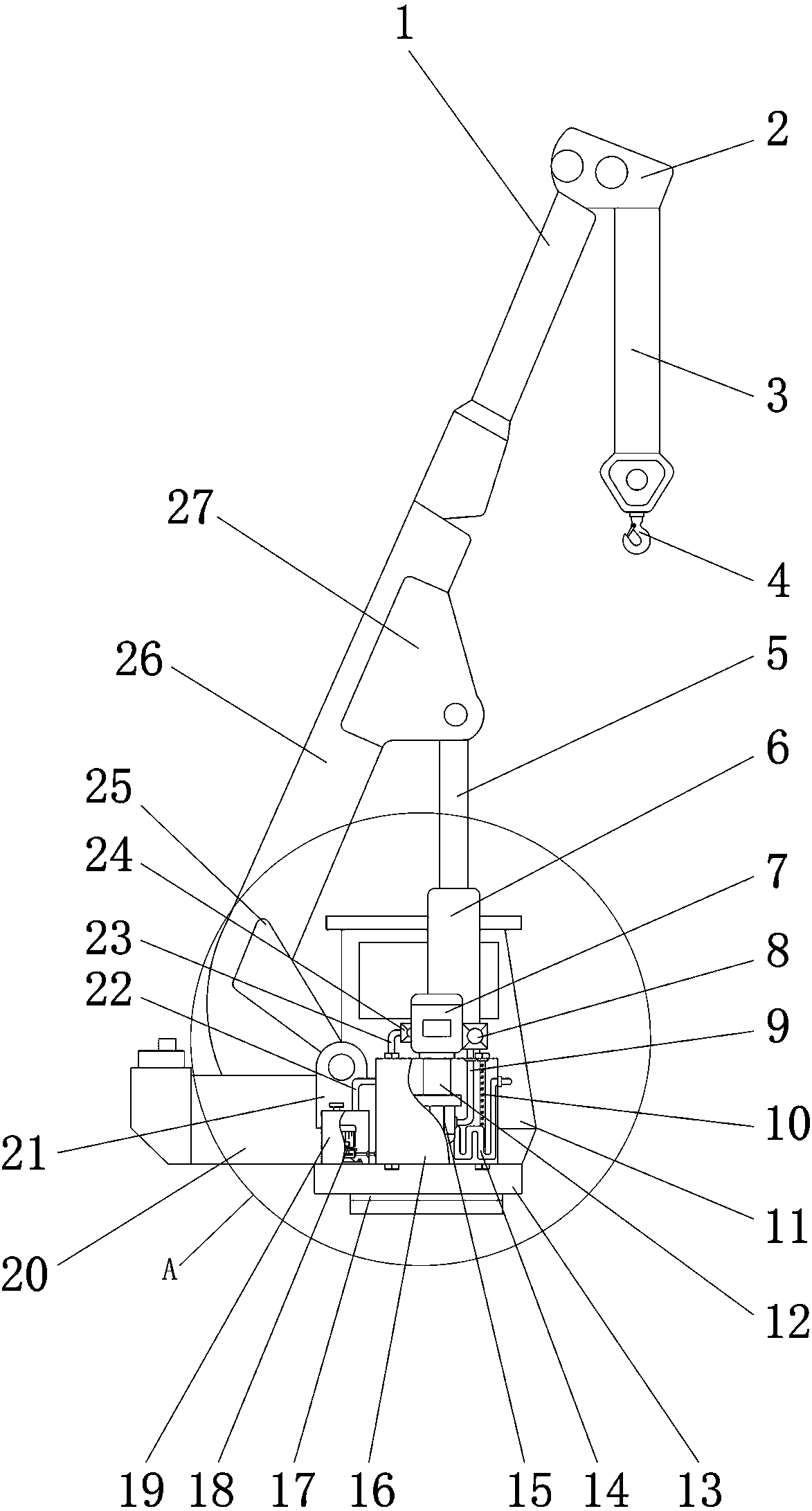

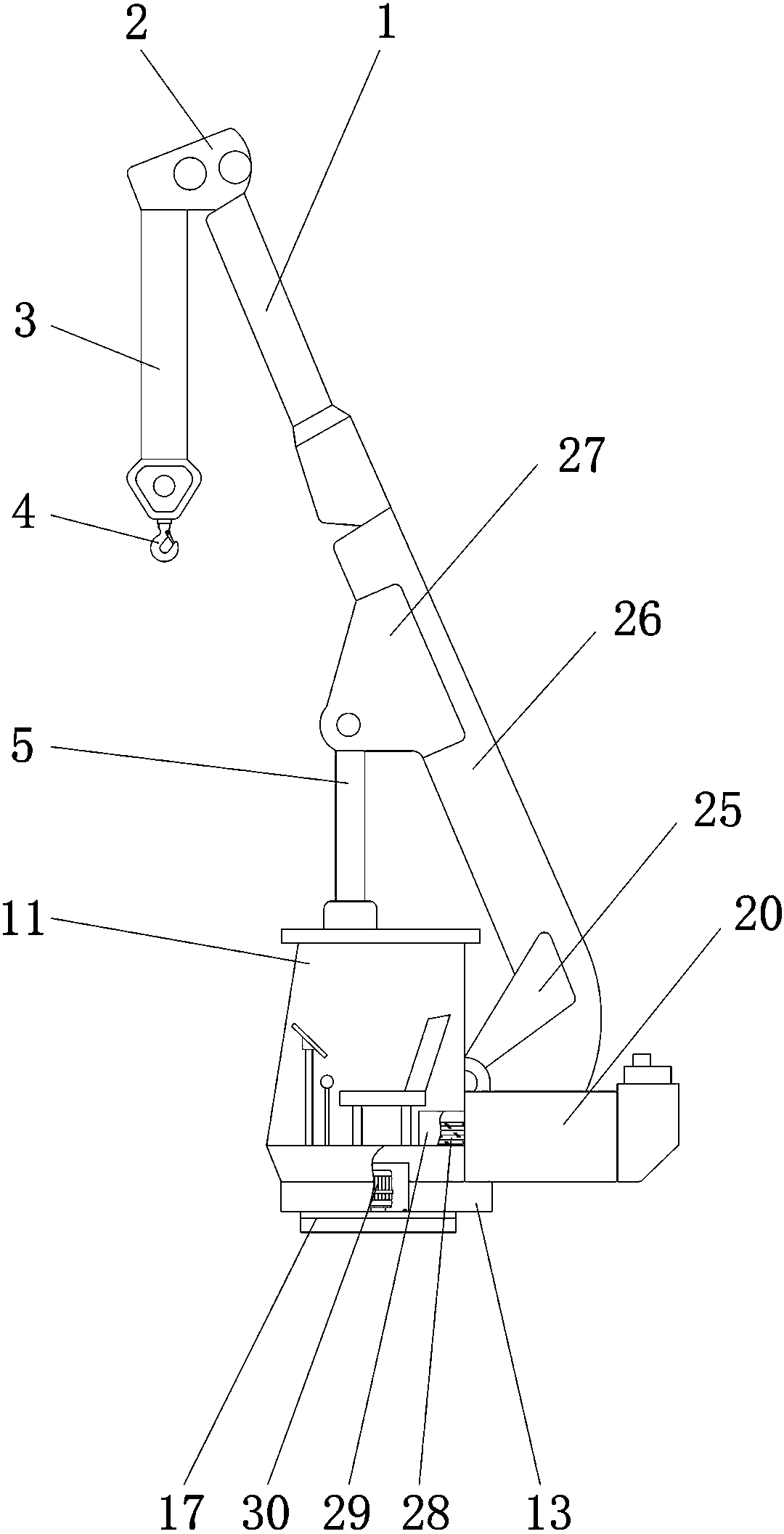

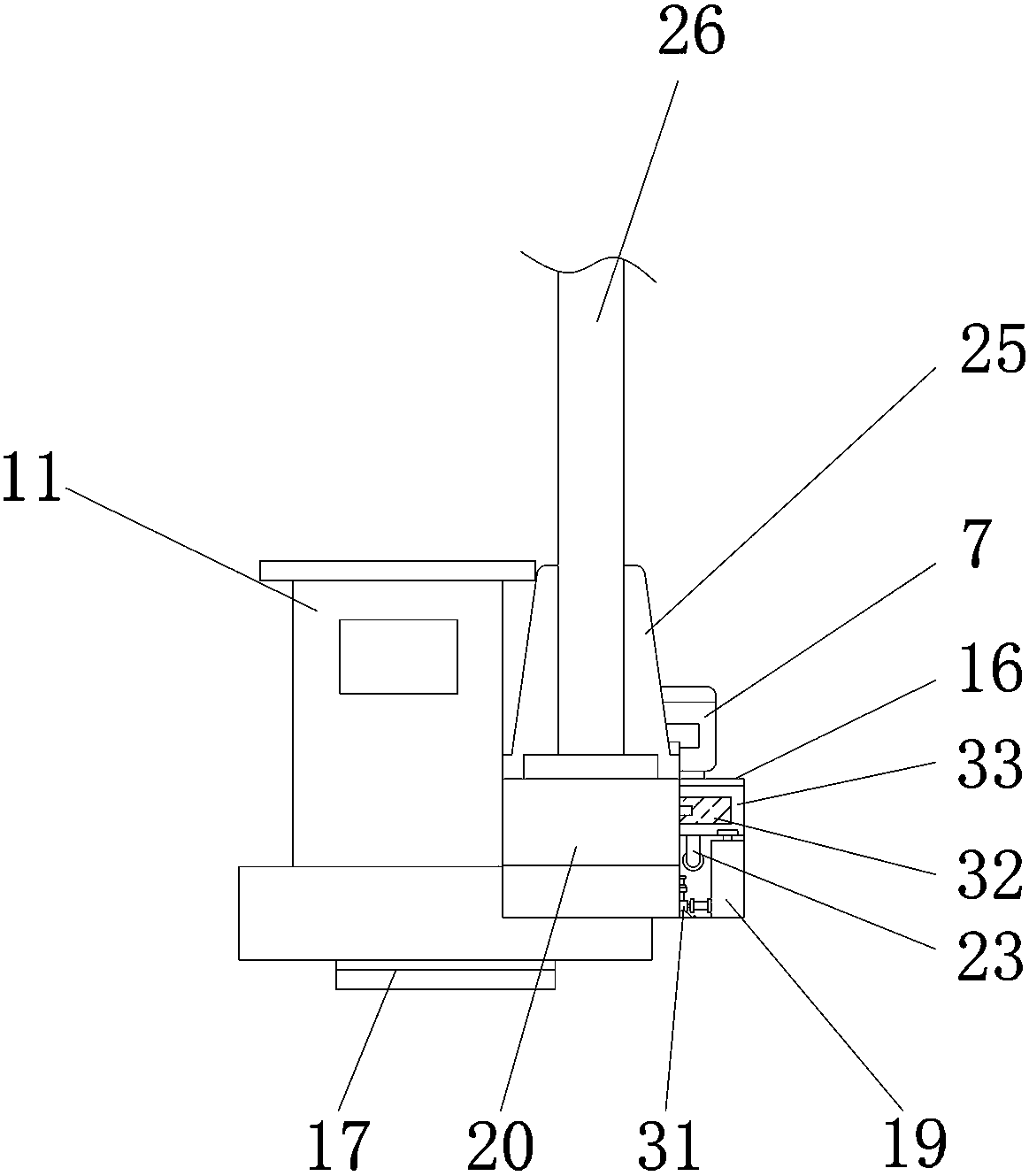

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The present invention provides a hydraulic system of a crane, comprising a base 13, a fuselage 20 is arranged on the top of the base 13, a turning mechanism 17 is arranged at the middle position of the bottom of the base 13, and a hydraulic motor 30 is arranged at an inner middle position of the turning mechanism 17; the fuselage 20 The top of the main arm 26 is fixed, and the top of the main arm 26 is equipped with a suspension hook 4 . The hydraulic motor 30 drives the slewing mechanism 17 to rotate, and then drives the fuselage 20 to rotate, so that the main arm 26 can be hoisted in different directions.

[0025] The top of the base 13 is also provided with a control room 11, through which the hoisting is operated, the control room 11 and the fuselage 20 are located on the same horizontal line, and the control room 11 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com